Making informed decisions for your plumbing, irrigation, or drainage needs is crucial. You need to consider critical factors when selecting plastic pipes and fittings. This helps you avoid common mistakes in material selection for your project. The global plastic pipe fitting market was valued at 37.61 billion USD in 2023. It is projected to reach approximately $27 billion by 2032, growing at a CAGR of 6.5% from 2024. This growth shows the increasing demand for durable and cost-effective piping solutions. These solutions are used in residential, commercial, industrial, and agricultural applications. For example, plastic pipes for agricultural irrigation are becoming very popular. You might wonder, "PVC vs. CPVC Pipes: Which One is Best for Your Plumbing Needs?" or how HDPE pipes and fittings fit into a water supply system plastic pipes. Understanding the PVC vs CPVC pipe comparison is key.

Key Takeaways

- Match the pipe type to your project needs. Consider temperature, pressure, and chemical resistance.

- Understand different plastic pipes. PVC, CPVC, PEX, ABS, and HDPE each have unique uses.

- Check local building codes. This ensures your project is safe and follows rules.

- Choose the right fittings and connection methods. They must match your pipe material.

- Think about long-term costs. This includes installation, maintenance, and durability.

Understanding Different Types of Plastic Pipes

What are PVC Plastic Pipes?

PVC pipes are a common choice for many projects. They are made primarily from polyvinyl chloride (PVC) polymer. This polymer forms from vinyl chloride monomer. The structure of PVC is similar to polyethylene, but it has a chlorine atom instead of a hydrogen atom. This means PVC contains about 55% chlorine by mass. This chlorine atom greatly affects PVC’s stiffness and its resistance to chemicals.

However, raw PVC is difficult to process. It has poor heat stability and can result in brittle parts if used alone. For this reason, PVC for pipes is a complex mixture. Manufacturers add many different substances to it. These additives include heat stabilizers, UV stabilizers, processing aids, and impact modifiers. They also add thermal modifiers, fillers, flame retardants, and sometimes pigments. The specific additives chosen depend on the cost and how the pipe will perform in its final use. Heat stabilizers are especially important because raw PVC has very poor heat stability. Adding them ensures the product keeps its properties during processing.

PVC pipes offer good performance within certain temperature limits. Standard PVC pipe can operate continuously up to 140°F (60°C) without pressure. For systems under pressure, it is best to keep temperatures below 100°F (38°C). This helps maintain enough pressure capacity. As the temperature rises, the pressure capacity drops significantly. For example, at 100°F, PVC loses about 40% of its pressure capacity. At 140°F, only about 22% of the original rating remains.

PVC can handle higher temperatures for short periods. Drainage systems, for instance, can tolerate discharges up to 212°F (100°C) for less than two minutes. This is an emergency tolerance, not a regular design parameter. When temperatures drop below 32°F (0°C), PVC becomes more brittle. This reduces its impact resistance. Pipes can crack from physical impact or bending during handling in cold environments. Therefore, careful handling is necessary in such conditions. Despite this, PVC pipe retains 70% to 90% of its room-temperature strength at 32°F. Field experience over fifty years shows its good performance in cold-weather installations.

What are CPVC Plastic Pipes?

CPVC plastic pipes are a step up from standard PVC. Manufacturers create CPVC by chlorinating PVC resin. This process adds more chlorine to the material. The extra chlorine makes CPVC pipes stronger and more resistant to higher temperatures and corrosive chemicals. This makes them suitable for applications where PVC might not perform well.

CPVC pipes can handle hot water better than PVC. They typically have a maximum operating temperature of 200°F (93°C). This is significantly higher than PVC’s limit. This higher temperature rating makes CPVC a popular choice for hot and cold water distribution in homes and businesses. It also works well in industrial applications that involve hot liquids or aggressive chemicals.

Like PVC, CPVC pipes are rigid. They connect using solvent cement, which creates strong, leak-proof joints. Installers appreciate CPVC for its ease of installation and long service life. It resists corrosion, scaling, and pitting, which are common problems with metal piping systems.

What are PEX Plastic Pipes?

PEX plastic pipes, or cross-linked polyethylene, offer a flexible alternative to rigid piping materials. Manufacturers create PEX through a process that cross-links polyethylene molecules. This process makes the material much more durable, flexible, and resistant to temperature extremes.

PEX pipes are known for their excellent resistance to both high and low temperatures. They can generally withstand a range from -40°C to 95°C. This wide range makes them suitable for use in cold climates and hot water systems. PEX pipes can even handle higher temperatures, up to 110°C, for short durations. This broad resistance makes them ideal for hot water supply and floor heating systems.

| Temperature Range | Performance Characteristics | Suitable Applications |

|---|---|---|

| 0-60°C | Optimal performance, minimal aging | Cold water supply, low-temperature floor heating |

| 60-80°C | Good performance, minor aging over long-term use | Domestic hot water systems |

| 80-95°C | Usable but with accelerated aging, requires regular inspection | High-temperature heating systems |

| >95°C | Not recommended for long-term use, potential for deformation/failure | Short-term emergency use only |

Installers often prefer PEX because of its flexibility. It can bend around corners, reducing the need for many fittings. This saves time and labor during installation. PEX also resists scale buildup and chlorine degradation. It does not corrode, making it a reliable choice for potable water systems. PEX pipes are available in various colors, often indicating their intended use: red for hot water, blue for cold water, and white for either.

What are ABS Plastic Pipes?

ABS plastic pipes are a popular choice for many drainage and vent systems. Acrylonitrile Butadiene Styrene, or ABS, is a thermoplastic polymer. It offers a good balance of strength, rigidity, and impact resistance. Manufacturers create ABS by polymerizing styrene and acrylonitrile in the presence of polybutadiene. This unique blend gives ABS its distinct properties.

The primary chemical compositions of ABS contribute to its overall performance:

| Component | Contribution |

|---|---|

| Acrylonitrile | Thermal and chemical stability |

| Butadiene | Toughness and impact resistance |

| Styrene | Rigidity and a smooth, glossy finish |

This combination makes ABS pipes very durable. They resist many chemicals and maintain their integrity over time. ABS pipes are also known for their ability to withstand cold temperatures. They perform effectively within a temperature range of -40°C to 80°C. This means they maintain high impact strength even in freezing conditions. This makes them suitable for outdoor installations in colder climates. Installers often use ABS for drain, waste, and vent (DWV) applications. They connect ABS pipes using solvent cement, which creates strong, leak-proof joints.

What are HDPE Plastic Pipes?

HDPE plastic pipes are a flexible and robust solution for various applications. High-Density Polyethylene, or HDPE, is a thermoplastic polymer. It is known for its high strength-to-density ratio. HDPE is primarily composed of ethylene monomers. These monomers polymerize to form its long molecular chains. Alpha-olefin monomers, such as butene, propylene, hexene, and octene, are also crucial components. Manufacturers use them in the production process to regulate the material’s density through copolymerization with ethylene. This gives HDPE its unique properties.

HDPE pipes offer excellent flexibility and resistance to corrosion. They do not rust, rot, or corrode. This makes them ideal for underground installations and harsh environments. HDPE plastic pipes also boast an impressive temperature resistance range. They can withstand temperatures as low as -50°C (-58°F) without becoming brittle. They handle up to 50°C (122°F) and can tolerate brief spikes up to 80°C (176°F) without losing their shape. Some specialized HDPE pipes, like nano-modified or glass fiber reinforced versions, can even withstand high temperatures of 150°C for extended periods. This wide range makes them suitable for diverse projects. People commonly use HDPE for water supply lines, gas lines, and agricultural irrigation systems. They often connect HDPE pipes using heat fusion. This creates a strong, leak-proof joint that is as strong as the pipe itself.

Matching Plastic Pipes to Project Applications

Choosing the right plastic pipes for your project depends heavily on the specific application. Different types excel in various environments, from residential homes to demanding industrial settings.

Which Plastic Pipes are Best for Residential Plumbing?

For residential plumbing, PEX pipes often stand out as a top choice. Their flexibility simplifies installation, reducing the need for many connections and lowering labor costs. This flexibility also enhances durability, minimizing leak risks and preventing breaks in freezing conditions. PEX-A, for example, expands and contracts with temperature changes, making it ideal for cold climates. Installers can easily snake PEX through walls and around corners, which speeds up the process. PEX resists rust and corrosion, ensuring long-term water quality and system efficiency. It also does not accumulate scale, a common issue with metal piping. PEX pipes withstand temperatures up to 210°F and pressures of 150 psi. They are generally cheaper to install and maintain compared to traditional copper piping. PEX also reduces noise, absorbing sound and eliminating water hammering.

Which Plastic Pipes are Best for Commercial and Industrial Use?

CPVC pipes are excellent for commercial and industrial applications. Their additional chlorine atoms protect the polymer’s carbon backbone from chemical attack and provide greater heat resistance. This allows CPVC to handle higher temperatures, up to 200°F (93°C), which is crucial for hot water supply lines and industrial processes. CPVC is inherently inert to acids, bases, salts, and aliphatic hydrocarbons, chemicals that typically corrode metals. This makes CPVC highly suitable for industrial environments. These plastic pipes resist corrosion, unlike metal pipes, which can rust. They are lightweight and easy to install with solvent cement, requiring minimal specialized tools. CPVC pipes offer a long lifespan, often over 50 years, resisting scale formation and maintaining consistent flow rates. They are also cost-effective, often more affordable than copper or other metal piping.

Which Plastic Pipes are Best for Drainage and Waste Systems?

ABS plastic pipes are a popular and effective choice for drainage and waste systems. They are shock-resistant, meaning they can withstand impacts and even minor earthquakes. Unlike other pipe materials, ABS pipes do not rust, preventing breakage and leaks over time. They also perform well in cold temperatures, resisting freezing and cracking, making them suitable for outdoor underground use. ABS pipes are lightweight, which makes installation quicker and simpler compared to heavier materials like steel and iron. This reduces labor time. ABS plastic is also inexpensive, leading to lower material costs for plumbing installations. Despite their low cost, ABS pipes are durable and long-lasting, often providing a lifespan of up to 50 years. They are also eco-friendly and recyclable.

Which Plastic Pipes are Best for Irrigation and Outdoor Applications?

For irrigation and outdoor applications, HDPE (High-Density Polyethylene) pipes are often the best choice. They offer a long lifespan, often over 50 years, without corrosion, rust, or aging. This holds true even in extreme climates and harsh geological conditions. HDPE pipes are highly flexible and impact-resistant. This allows them to adapt to unstable environments like earthquakes and soil settlement, which reduces the risk of rupture.

HDPE pipes also feature a leak-free joint system. Installers use butt fusion or electrofusion welding to create monolithic connections, which prevents leakage. These pipes show excellent corrosion and chemical resistance, maintaining stability when transporting acids, alkalis, or other industrial chemicals. Their smooth inner wall ensures high flow efficiency, reducing friction and pumping energy consumption. HDPE is lightweight, making transport, cutting, and welding easier. This contributes to easy installation and cost efficiency. They are also eco-friendly and sustainable, as the material is recyclable with a long lifecycle and low maintenance needs. HDPE pipes have superior UV resistance, preventing degradation from prolonged sun exposure, which makes them ideal for outdoor use. They can withstand extreme temperatures for stable operation in various climates. This makes them versatile for agricultural and horticultural settings, including transporting water to crop rows, precise water distribution in greenhouses, drip irrigation, and sprinkler systems. They are also ideal for livestock watering because they are non-toxic and durable.

Which Plastic Pipes are Best for Specialized Chemical Transport?

When it comes to specialized chemical transport, both PE (polyethylene) and PVC (polyvinyl chloride) pipes offer strong advantages. PE pipe has superb chemical resistance and is a top material choice in harsh chemical environments. It works well in various mineral processes, from low pH acids to high pH caustic solutions. PE pipe is also abrasion-resistant, making it suitable for solids environments in mining applications. Its heat-fused joints create a monolithic structure, and these leak-free joints have proven long-term reliability in demanding environments. The polyethylene pipe industry estimates a service life of 50-100 years, which saves on replacement costs. PE pipe is also pressure surge resistant. Its flexible nature expands with pressure surges, increasing pipeline life and reducing maintenance costs.

PVC pipes also show excellent resistance to many chemical reagents and disinfectant chemicals. This makes them a top choice for carrying strong acids, alkalis, aqueous solutions, fluorides, plating solutions, brine, and mineral oils. PVC pipes are invulnerable to underground external and internal corrosion. They have the lowest pipe break rate compared to other materials. The smooth surface of PVC pipes allows for leak-free joints, reducing water loss. Their elastomeric seals enable quick and easy joining without electricity. Studies show the life expectancy of PVC pipes can be over 100 years, which reduces water main breaks and maintenance costs. The smooth lining of PVC pipes decreases water flow resistance, reducing potential blockages and ensuring free flow of water. This also helps prevent build-up in sewage and wastewater systems. These plastic pipes are durable, lightweight, and resistant to chemical corrosion, making them cost-effective for large-scale installations.

Key Factors for Selecting Plastic Pipes and Fittings

Choosing the right plastic pipes and fittings involves looking at several important details. These factors ensure your project works well and lasts a long time.

What Pressure and Temperature Ratings Do I Need?

Understanding the pressure and temperature limits of plastic pipes is very important. Each type of plastic pipe handles different conditions. You must match the pipe’s ratings to your project’s needs.

For example, PEX tubing has specific pressure ratings. All PEX tubing sold in the U.S. has a standard hydrostatic rating of 160 psi at 73℉. However, these ratings can change based on the manufacturer, the type of PEX (A, B, or C), and how thick the pipe wall is. PEX A is known for its high burst pressure resistance. It can hold up to 500 psi. When the temperature goes up, the pressure rating often goes down.

Here is a quick look at some common ratings:

| Material | Temperature | Pressure Rating |

|---|---|---|

| PEX | 73℉ | 160 psi (630 HDB) |

| PEX | 180℉ | 100 psi |

| PEX A | N/A | Up to 500 psi |

PVC is another common plastic pipe. It is light and easy to move. People use it for drinking water and sewage. PVC also resists heat and chemicals. Always check the specific product details for exact pressure ratings.

Temperature ratings are also key. CPVC and HDPE pipes have different temperature limits. Corzan CPVC can handle pressurized service up to 200°F. It generally offers higher pressure ratings across its useful temperature range compared to most other industrial plastic pipes. Some HDPE grades can be pressure rated up to 180°F. However, their maximum pressure at higher temperatures is lower than Corzan CPVC.

Consider these temperature ranges for different materials:

| Material | Working Temperature Range | Maximum Short-Term Tolerance Temperature | Heat Deformation Temperature |

|---|---|---|---|

| CPVC | -20°C to 93°C | Up to 110°C | Approximately 103°C |

| HDPE | -40°C to 60°C | N/A | Approximately 80°C (for PE80/100) |

You can see that Corzan CPVC has a glass transition temperature (Tg) of 275°F and a heat deflection temperature (HDT) of 230°F. HDPE has a Tg of -166°F and an HDT of 140°F. These numbers show how well the material handles heat. Always choose pipes that can safely manage the highest temperatures and pressures your system will experience.

What Chemical Resistance and Compatibility are Required?

The chemicals your pipes will carry are a big deal. You need to pick pipes that will not break down or react with these substances. Different plastic pipes offer different levels of chemical resistance.

PVC pipes resist many common household chemicals. They handle many alcohols, fats, oils, and gasoline without aromatics. They also resist most corroding agents. This includes inorganic acids, alkalis, and salts. PVC pipes are good with ammonium hydroxide, iodine, and sodium hydroxide (up to 30% concentration). They also work well with ammonium nitrate, acetylene, aluminum chloride (anhydrous and 20% concentration), and silver nitrate. You can use them for distilled water and deionized water too.

However, some chemicals can harm PVC pipes. These include tetrahydrofuran, acetone, xylene, and methyl ethyl ketone (MEK). Some alcohols can also cause issues, depending on their type and concentration.

Several things affect how well PVC pipes resist chemicals:

- Temperature: Resistance goes down as temperatures rise. Above 140°F (60°C), you should test the pipe first. Higher temperatures speed up chemical attacks.

- Chemical Concentration: Stronger chemicals cause faster damage. Below certain levels, the effect might be very small.

- Contact Time: Longer exposure to chemicals can increase the rate of attack. This can make the pipe soft, weak, or swollen.

- Plasticizers: PVC without plasticizers usually resists chemicals better.

Here is a look at how PVC resists various chemicals:

| Chemical | Resistance |

|---|---|

| Sodium Bisulfate | R |

| Sodium Bisulfite | R |

| Sodium Bromide | R |

| Sodium Carbonate | R |

| Sodium Chlorate | R |

| Sodium Chloride | R |

| Sodium Chlorite | N |

| Sodium Cyanide | R |

| Sodium Dichromate | R |

| Sodium Phosphate | R |

| Sodium Ferricyanide | R |

| Sodium Hydroxide | R |

| Sodium Hypochlorite | R23 |

| Sodium Meta-Phosphate | R |

| Sodium Nitrate | R |

| Sodium Silicate | R |

| Sodium Sulfate | R |

| Sodium Sulfide | R |

| Sodium Sulfite | R |

| Sodium Thiosulfate | R |

| Stannic Chloride | R |

| Stannous Chloride | R |

| Stearic Acid | R |

| Sugar, Sucrose | R |

| Sulfamic Acid | N |

| Sulfuric Acid 0-80% | R |

| Sulfuric Acid 90% | R23 |

| Sulfuric Acid > 93% | N |

| Sulfurous Acid | R |

| Tall Oil | R |

| Tannic Acid | R |

| Tartaric Acid | R |

| Toluene (Toluol) | N |

| Transformer Oil | R |

| Trichloroacetic Acid 50% | R |

| Trisodium Phosphate | R |

| Urea | R |

| Vegetable Oils | R |

| Vinegar | R |

| Water – Deionized | R |

| Water – Demineralized | R |

| Water – Distilled | R |

| Water – Fresh | R |

| Water – Salt | R |

| Water – Sea | R |

| White Liquor – Pulp Mill | R |

| Wine | R |

| Xylene (Xylol) | N |

| Zinc Chloride | R |

| Zinc Nitrate | R |

| Zinc Sulfate | R |

(Note: R = Resistant, N = Not Resistant, R23 = Resistant with caution)

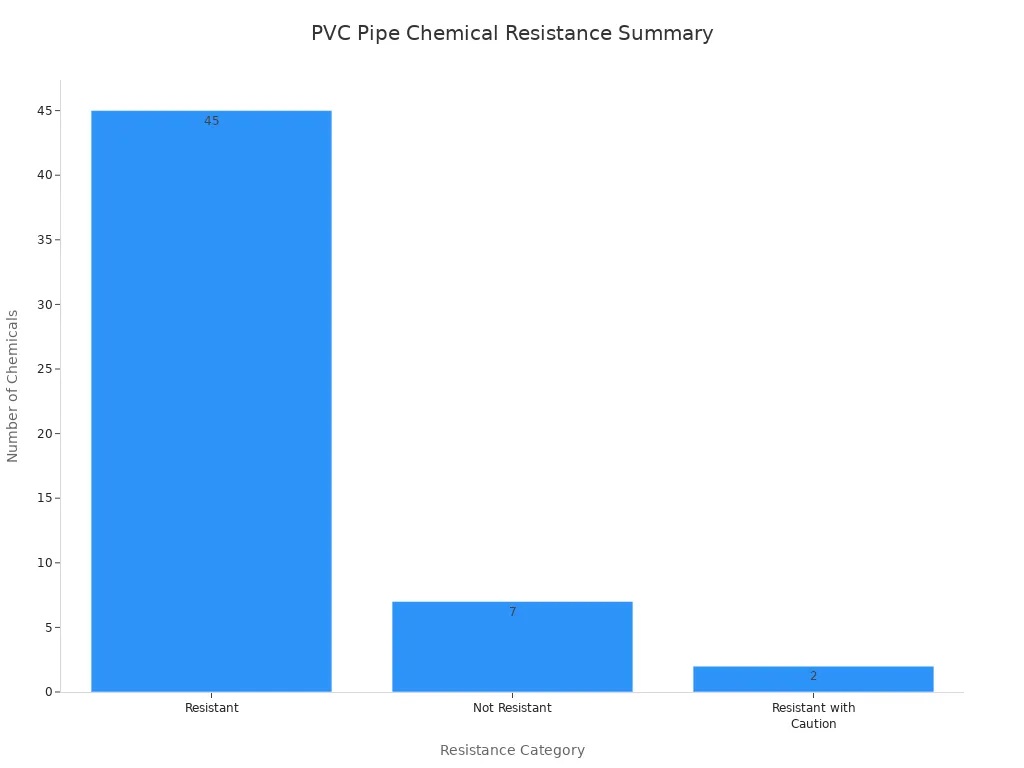

This chart shows the general resistance of PVC pipes to many chemicals:

CPVC pipes offer even broader chemical resistance. Industries use CPVC widely for pressure and chemical process applications. It resists strong acids and alkalis. CPVC is especially good against oxidizers and sodium hypochlorite solutions. It also resists some dilute water-soluble solvents. However, CPVC has limited resistance to certain strong, concentrated solvents. Always check a chemical resistance chart for your specific application.

How Do I Assess Durability and Lifespan?

You want your piping system to last a long time. Durability and lifespan are key factors. Different plastic pipes have different expected lifespans, and many things can affect how long they actually last.

PVC pipes are known for their long life. PVC systems can last 50 years or more under normal conditions. Some research even suggests properly made PVC piping can last 100 years or more. This is true even in tough conditions like extreme temperatures and corrosive soils. PVC pipes typically last between 70 to 100 years in systems for drinking water and sewage. They resist rust, corrosion, and many chemicals, which helps them last longer.

PEX piping systems also offer good durability. PEX pipes are generally designed to last 40 to 50 years or more. This is true when you install and maintain them correctly. Several factors influence how long PEX plumbing actually lasts:

- Water Temperature and Pressure: Higher operating temperatures significantly shorten PEX lifespan. For example, PEX might last over 50 years at 60-70°F but only 20-30 years at 180°F. Constant pressure surges or water hammer events also add stress.

- Chemical Exposure: Chlorine and chloramine disinfectants in water can slowly break down PEX polymers. This can reduce lifespan by 10-20 years, especially with high disinfectant levels, warmer water, and constant exposure. Other chemicals like cleaners, pesticides, or petroleum can also degrade PEX.

- UV Radiation: Direct sunlight is a big threat. UV radiation can make PEX brittle and cause tiny cracks within months.

- Mechanical Stress: How much stress the pipes experience from bending or external forces matters.

- Installation Quality: Proper installation is very important. Bad installation can lead to leaks and a shorter lifespan.

- Manufacturing Quality: PEX made to standards like ASTM F876, F877, and NSF/ANSI 61 usually performs better. PEX-A often resists stress cracks and fatigue better than PEX-B or PEX-C.

- Water Quality: Hard water with lots of minerals can cause buildup. Extreme pH levels can affect fittings. Rodent activity can also damage PEX.

To ensure your pipes last, consider all these factors. Choose a pipe material that can handle the specific conditions of your project for many years.

What Installation Complexity and Tools are Involved?

The type of plastic pipe you choose directly impacts how complex the installation will be and what tools you need. Some pipes are very flexible, making them easier to route through tight spaces. Others are rigid and require more precise measurements and cuts.

PEX pipe, for example, offers great flexibility, which often simplifies installation. Installers can bend PEX around corners, reducing the number of fittings needed. This saves time and labor. However, PEX systems do require specialized tools for proper connections. A PEX cutter makes clean, square cuts on the tubing, which prevents leaks. For press-style PEX systems, professional installers often use battery press tools and jaws to compress sleeves or fittings securely. When attaching PEX tubing to wood framing, subfloors, or walls, manual and pneumatic clip guns come in handy, using plastic clips. For radiant floor systems, foam staplers secure PEX tubing to foam board insulation with plastic staples. Installers also use PEX-to-wire mesh tools to quickly tie tubing to welded wire in slab or over-pour radiant heating.

Different PEX connection methods also require specific tools. A calibrated crimp tool compresses a copper crimp ring uniformly around a barbed fitting in crimp systems. After crimping, a Go/No-Go gauge verifies the crimp ring has been compressed to the correct diameter. If a crimp needs removal, a de-crimping tool cuts copper crimp rings without damaging the fitting. For cold-expansion systems, an expander tool enlarges PEX-A tubing and an expansion ring before inserting a fitting. Finally, a clamp tool, also known as a cinch tool, tightens a stainless-steel clamp ring around tubing and a barbed fitting with a single pinch action in clamp systems.

PVC and CPVC pipes are rigid. Installers typically join them with solvent cement. This process requires careful application and proper curing times. While it does not need as many specialized tools as PEX, precise cutting and fitting alignment are crucial for strong, leak-free joints. HDPE pipes often use heat fusion for connections. This method creates a very strong, seamless joint, but it requires specialized heat fusion equipment and training. ABS pipes also use solvent cement, similar to PVC, making their installation straightforward for drain, waste, and vent applications.

How Do I Evaluate Cost-Effectiveness and Budget?

When you choose plastic pipes, you need to think about more than just the upfront cost. Consider the long-term cost-effectiveness and how it fits your budget. This includes material costs, installation labor, and future maintenance.

Some plastic pipes, like PEX, can reduce labor costs because they are flexible and require fewer fittings. This makes installation quicker. However, the specialized tools for PEX can add to the initial investment. PVC and ABS are generally less expensive per foot than PEX or CPVC, making them attractive for budget-conscious projects. CPVC often costs more than PVC but offers superior performance in high-temperature or chemical applications, which can save money on repairs later. HDPE pipes might have a higher initial material cost, but their durability and long lifespan can lead to significant savings over time.

Long-term maintenance costs also play a big role in the overall budget. PVC pipes can crack under freezing conditions or heavy impact, which leads to joint failures. PEX pipes resist freezing, but improper installation can lead to fitting failures. PEX can also suffer UV damage if exposed to sunlight for too long.

When pipes need repair or replacement, the costs can vary widely. Pipe lining, which costs about $80–$250 per foot, is less disruptive and works well for pipes that are still structurally sound. A full replacement can cost $150–$450 per foot, but it offers a longer service life. Cured-in-place pipe (CIPP) is a trenchless method that costs $100–$300 per foot. It extends pipe life by 30-50 years, depending on the pipe’s diameter and length. Excavation, which costs $50–$150 per foot, is labor-intensive and necessary for severe damage. After excavation, site restoration can add another $500–$5,000 or more to the total cost, depending on the landscaping or pavement that needs repair.

Environmental factors also influence long-term costs. PVC and other plastics have a high carbon footprint because their manufacturing uses a lot of energy and relies on fossil fuels. While they are lighter, which reduces transport emissions, they often end up in landfills because recycling options are limited. This can release greenhouse gases as they degrade or if they are incinerated. In contrast, materials like ductile iron and copper, despite higher production emissions, are highly recyclable. This reduces their long-term environmental impact and waste generation.

What Local Building Codes and Regulations Apply to Plastic Pipes?

Local building codes and regulations are critical for any piping project. They ensure safety, proper function, and compliance with environmental standards. Always check with your local authorities before starting any installation.

For burying plastic pipe in underground drain, waste, and vent (DWV) applications, specific guidelines and industry standards must be followed. Plastic pipe and fittings should be buried strictly according to the ASTM standard relevant to the type of plastic piping system you are installing. Key industry standards include ASTM D2321 for underground installation of thermoplastic pipe for sewers and other gravity-flow applications. ASTM D2774 covers the underground installation of thermoplastic pressure piping. ASTM F1668 provides a standard guide for construction procedures for buried plastic pipe. In addition to these standards, plastic piping systems must also follow local code requirements.

Proper bedding and backfill are crucial for PVC and ABS piping in underground applications. This helps them withstand external live and earth loads. Installers must dig a trench larger than the pipe, install the foundation and bedding, and compact the material to the spring line of the pipe. Installation should follow ASTM D2321.

The Pipeline and Hazardous Materials Safety Administration (PHMSA) often proposes revisions to regulations concerning plastic pipe installation. For example, PHMSA has proposed prohibiting the use of PVC pipe for new installations and repairs after a rule’s effective date. However, existing PVC pipe and components for repair would still be allowed. PHMSA also proposes a new section, § 192.67, requiring operators to have written procedures for plastic pipe storage and handling. For gathering lines, a new paragraph (d)(7) would specify compliance with all Part 192 requirements applicable to plastic pipe.

PHMSA also aims to merge and clarify design requirements for plastic pipe in §§ 192.121 and 192.123. This includes increasing the maximum design factor for PE pipe and adding design and pressure limitations for PA-11 and PA-12 pipes. Revisions are also proposed for mechanical fittings, requiring them to provide a Category 1 joint as defined in ASTM F1924, ASTM F1948, and ASTM F1973. This ensures resistance to lateral forces. For trenchless excavation, new sections §§ 192.329 and 192.376 would detail requirements for sufficient clearance from other utilities and the use of a ‘weak link’ to prevent damage during pulling. Revisions to § 192.281 clarify solvent cement requirements for PVC pipe and heat-fusion joint requirements for both pipe and components. A new paragraph (e)(3) would require mechanical fittings to meet listed specifications. Finally, § 192.283 would be revised to refer operators to appropriate listed specifications for qualifying plastic pipe joining procedures.

Specific regulations for plastic pipe installation also include other important points. The pipe must adequately resist exposure to ultraviolet light and high and low temperatures. When installed on bridges, plastic pipe must be protected from mechanical damage, for example, by placing it in a metallic casing. It also needs protection from ultraviolet radiation. The pipe must not exceed the temperature limits specified in § 192.121. Plastic mains may terminate above ground level if the above-ground part is protected against deterioration and external damage. The plastic main must not be used to support external loads. Installations of risers at regulator stations must meet the design requirements of § 192.204.

Choosing the Right Plastic Fittings and Connection Methods

Selecting the correct plastic fittings and connection methods is just as important as choosing the right pipes. Fittings help you change direction, join pipes, or connect to other components. The connection method ensures a strong, leak-proof system.

What Types of Fittings are Available?

Many types of fittings exist for plastic pipes. Each one serves a specific purpose in your plumbing system. For PVC pipes, you will commonly find these fittings:

- Tees: These fittings have three ends. Two ends are in a straight line, and one is at a 90-degree angle. People use them to split or combine lines in plumbing and structures.

- Elbows: Elbows help divert pipe direction. They come in 45- or 90-degree bends. Side elbows have three ends and work well for corners.

- Crosses: These fittings are like tees but have four slip connections at 90-degree angles. They form a plus shape. People use them to divide fluid flow in four directions or for framework.

- Couplings and Unions: Couplings connect two pipes or a pipe to a fitting, often permanently. Unions are similar but allow for easy removal and reattachment without cutting the pipe.

- Caps and Plugs: Caps stop flow at the end of a pipeline. Plugs stop flow inside a fitting.

- Adapters and Bushings: Adapters change the end type of a pipe to connect different sizes. Bushings connect pipes of varied diameters by reducing the fitting.

What Connection Methods Should I Use?

The connection method depends on the type of plastic pipe. For PVC and CPVC pipes, solvent cementing is common. This method uses a special glue to create a strong, fused joint. HDPE pipes often use heat fusion. This process melts the pipe ends together, forming a seamless, very strong bond. PEX pipes use mechanical connections. These include crimp rings, expansion rings, or compression fittings. Each method requires specific tools and techniques for a secure connection.

How Do I Ensure Material Compatibility for Plastic Pipes?

Ensuring material compatibility is crucial. Always use fittings made from the same material as your pipes. For example, use PVC fittings with PVC pipes. Mixing materials can lead to chemical reactions, different expansion rates, or weak joints. This can cause leaks or system failure. Manufacturers design pipes and fittings to work together. Always check product specifications to confirm compatibility. This step helps you build a reliable and long-lasting system.

Selecting the best plastic pipes and fittings requires careful thought. People confidently choose materials by understanding their project’s specific needs. They match pipe properties like pressure, temperature, and chemical resistance to the application.

To ensure project longevity and efficiency, people must select the right materials. Proper installation and adherence to local building codes are also crucial. These steps prevent future problems and ensure the system works well for many years.

Here are key takeaways for your next project:

- Research different plastic pipe types thoroughly.

- Always ensure material compatibility between pipes and fittings.

- Plan carefully, considering all project requirements and regulations.

FAQ

What is the most important thing to consider when choosing plastic pipes?

The most important thing is to match the pipe’s properties to the project’s needs. Consider pressure, temperature, and chemical resistance. Also, check local building codes. This ensures safety and a long-lasting system.

Can you use PVC for hot water?

No, you should not use standard PVC for hot water. PVC’s pressure capacity drops significantly at higher temperatures. CPVC pipes are a better choice for hot water applications. They handle temperatures up to 200°F (93°C).

Which plastic pipe is best for outdoor use?

HDPE pipes are excellent for outdoor use. They resist UV radiation, extreme temperatures, and corrosion. Their flexibility also helps them adapt to unstable ground conditions. This makes them ideal for irrigation and other outdoor applications.

Do all plastic pipes use the same connection method?

No, different plastic pipes use various connection methods. PVC and ABS pipes often use solvent cement. HDPE pipes typically use heat fusion. PEX pipes use mechanical connections like crimp rings or expansion fittings.

What are the benefits of using plastic pipes over metal pipes?

Plastic pipes offer many benefits. They resist corrosion, are lightweight, and often cost less to install. They also have smooth inner surfaces, which reduces friction and prevents buildup. This leads to better flow and longer system life.