Reliable pipe fittings are essential for project success. They ensure durability and high performance in any system. Careful Pipe Fittings Selection prevents costly failures and maintains operational integrity. Engineers must consider various factors for compatibility. For instance, industrial pipe fittings for construction sites demand robust materials. Project managers often ask, "What pipe fittings are suitable for irrigation?" PVC Pipe Fittings are a common choice for many applications. Ensuring compatibility, especially for PVC fittings for irrigation systems, is vital. One must also understand "How to ensure pipe fitting compatibility with existing systems?" to avoid issues.

Key Takeaways

- Always check what liquid flows through pipes. Different liquids need different pipe materials to stop leaks and damage.

- Match pipe fittings to the right temperature and pressure. Using the wrong fitting can cause pipes to break or leak.

- Think about where pipes will go. Sunlight, rain, and soil can damage pipes, so pick materials that can handle these conditions.

- Choose the right material for your pipes. PVC is good for water, but metal or special plastics are better for strong chemicals or high heat.

- Make sure new pipe parts fit old ones. Check their size, material, and how they connect to avoid big problems later.

Evaluate Project Needs for Optimal Fitting Selection

Determine Fluid Type and Chemical Compatibility

Project managers must first identify the fluid type flowing through the system. Different fluids possess unique chemical properties. These properties dictate the required material for pipe fittings. For example, aggressive chemicals demand specialized corrosion-resistant materials. Water, oil, or gas each require specific fitting compositions to prevent degradation and leaks. Chemical compatibility ensures the long-term integrity of the entire piping system.

Assess Operating Temperature and Pressure Ratings

Engineers must carefully evaluate the system’s operating temperature and pressure. These factors directly influence fitting performance and lifespan. API 5L Grade B pipe offers reliable performance across a range of temperatures, from sub-zero to moderately high. This pipe is suitable for large-scale water transportation and construction. However, extreme temperatures may require higher-grade materials.

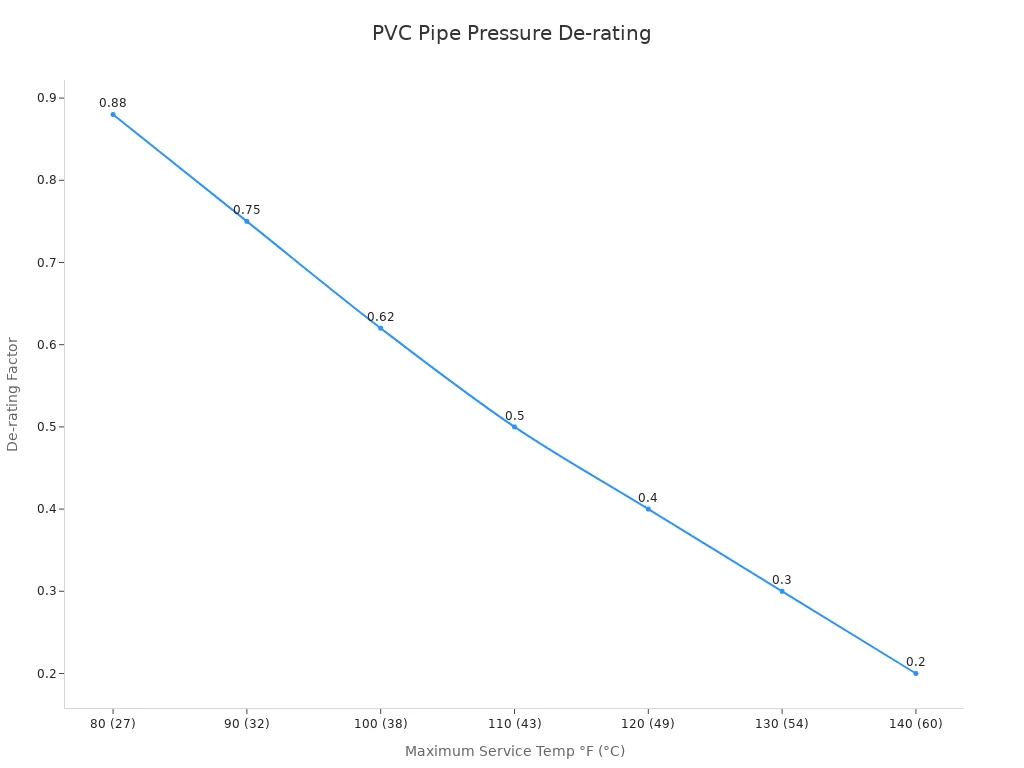

PVC pipe has a maximum operating temperature of 140°F (60°C). Its pressure rating decreases at higher temperatures. For instance, at 100°F (38°C), the pressure class is de-rated to 62% of its 73.4°F (23°C) rating.

| Maximum Service Temp °F (°C) | Multiply pressure class at 73.4°F (23°C) by factor shown |

|---|---|

| 80 (27) | 0.88 |

| 90 (32) | 0.75 |

| 100 (38) | 0.62 |

| 110 (43) | 0.50 |

| 120 (49) | 0.40 |

| 130 (54) | 0.30 |

| 140 (60) | 0.20 |

Pressure ratings also vary significantly by fitting type and material. Class 150 malleable iron fittings handle approximately 300 psi for water, oil, and gas. They suit general plumbing and low-pressure steam. Class 300 malleable iron fittings manage around 2000 psi for water, oil, and gas, ideal for high-pressure industrial applications. Stainless steel fittings can withstand up to 1000 psi for demanding uses.

| Fitting Type | Material | Pressure Rating (PSI) | Notes |

|---|---|---|---|

| Elbows / Tees / Couplings | Malleable Iron | 150 – 300 | For general plumbing systems |

| Heavy-duty Unions | Malleable Iron | 300 – 600 | Fire protection / industrial |

| Stainless Steel Fittings | Stainless Steel | Up to 1000 | High-pressure applications |

Consider Environmental Exposure and UV Resistance

The installation environment plays a crucial role in fitting selection. Outdoor applications expose fittings to sunlight, rain, and extreme temperatures. UV radiation significantly impacts plastic pipes like ABS, CPVC, and PVC. Prolonged UV exposure causes several issues:

- Color change: PVC often turns yellow or brown.

- Surface cracking: The plastic surface becomes brittle.

- Lowered impact strength: Pipes become more prone to damage.

- Heat buildup: Radiant heat can increase pipe surface temperatures.

- Decreased lifespan: Overall, UV exposure shortens the functional life of plastic pipes.

For PEX, UV light destroys chlorine-inhibiting antioxidants. This makes the pipe vulnerable to chlorine degradation and premature failure. Some manufacturers advise protecting PEX from fluorescent and LED lighting within five feet. Selecting UV-resistant materials or providing adequate shielding is essential for outdoor installations.

Account for Soil Conditions and Burial Depth

Project success often depends on understanding the ground where engineers install pipes. Soil conditions significantly influence the longevity and performance of buried pipe fittings. Soil is a porous, gelatinous capillary with solid, liquid, and gas phases. Its pores contain air and water. The presence of salt in the water provides ionic conductivity. The combination of the soil’s physical and chemical properties and the electrochemical inhomogeneity of the metal material creates the conditions necessary for electrochemical corrosion in buried pipelines.

Engineers must consider several factors regarding soil corrosivity:

- Dissimilar Soils: Laying a pipeline across undisturbed local soil and backfilled dissimilar soil, or entirely dissimilar soils, can create corrosive cells.

- Corrosive Elements: The presence of sulfates, chlorides, and other acidic contents in soil increases corrosion potential. Corrosive chlorides in soil can originate from tidal flows or ocean currents, carrying saltwater droplets inland.

- Soil Composition: Clay content and moisture in soils contribute to corrosion. Soils with high sand content are less corrosive due to higher electrical resistance. Shifting soils can worsen pipe damage.

- Fuel-Generated Combustion Products: Soils containing sulfur compounds and nitrogen from fuel combustion reduce resistivity and increase corrosion potential.

- Moisture Content: Soil moisture, influenced by climate and groundwater levels, affects corrosion. Shifting groundwater levels and the temperature of moist air can increase corrosion. Below freezing point, high soil resistivity leads to low corrosion potential.

- Oxygen Levels: Disturbed (filled) soils have higher oxygen content, supporting vigorous corrosion at cathodic regions. Undisturbed soil has lower oxygen. Soil aeration impacts moisture and oxygen availability for electrochemical corrosion.

- Soil Resistivity: Lower soil resistance leads to higher current flow and accelerated corrosion. Salt-polluted ground and clay soils are more corrosive than gravel and sandy soils. Dry gravel may not require cathodic protection or coatings.

Buried metallic pipes are prone to specific types of corrosion:

- Graphitization Corrosion: Grey cast iron pipes fail due to graphitization. Residual graphitic flakes intersperse with ferrous oxides, weakening the pipe and making it susceptible to failure. This also includes localized pitting corrosion depending on soil conductivity.

- Galvanic Corrosion: This occurs when dissimilar metals, such as ductile iron and copper, are used. Copper becomes cathodic to iron.

- Microbiological Corrosion (MIC): Both aerobic and anaerobic microbes (bacteria) cause MIC. Sulfate-reducing bacteria, in the presence of sulfur compounds, can significantly accelerate corrosion. Anaerobic microorganisms can release oxygen from compounds like carbonates and sulfates for corrosion reactions, even without dissolved oxygen. MIC can accelerate corrosion rates by more than ten times compared to sterile conditions.

Proper burial depth protects pipes from surface loads, frost, and external damage. It also helps maintain a stable temperature environment. Selecting appropriate materials and protective coatings becomes critical when considering these soil and depth factors.

Choosing the Right Material, Including PVC Pipe Fittings

Selecting the correct material for pipe fittings ensures system longevity and performance. Engineers consider various material properties for different applications.

Understanding PVC and CPVC Applications

PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) are popular choices for many piping systems. PVC Pipe Fittings offer cost-effectiveness, light weight, and excellent corrosion resistance. They require low maintenance and provide versatility for various projects. CPVC, a more robust version of PVC, handles higher temperatures and pressures.

CPVC pipe fittings are highly effective in demanding industrial environments. They handle harsh chemicals like sulfuric, hydrochloric, and nitric acids. They also resist bases such as caustic (NaOH) and magnesium hydroxide. Industries widely use CPVC in:

- Wastewater Treatment: For handling aggressive chemicals.

- Pulp and Paper: Ideal for bleaching operations and various liquor processes.

- Food and Beverage: Suitable for frequent cleaning with harsh chemicals and high-temperature agents.

- Chemical Processing: Successfully installed in various chemical transport systems.

- Chlor-alkali Industry: Transports highly corrosive chemicals like sulfuric acid and sodium hypochlorite.

- Metal Finishing: A viable alternative to metal due to resistance to strong acids and high-pH caustics.

Exploring Metal Fittings: Steel, Copper, and Brass

Metal fittings offer strength and durability for specific applications. Copper, brass, and steel each provide unique benefits.

| Material | Typical Applications in Construction |

|---|---|

| Copper | Plumbing, refrigeration, and HVAC systems |

| Brass | Plumbing, gas pipelines, and fire protection systems, water distribution networks |

| Alloy Steel | High-temperature and pressure applications (e.g., power plants) |

| Carbon Steel | High-pressure applications (e.g., power plants) |

Copper and brass are valuable for their thermal conductivity and machinability. They are crucial in HVAC systems, providing durable, leak-proof connections for refrigerant and chilled water lines. Steel fittings, including alloy and carbon steel, manage high-pressure and high-temperature systems, such as those found in power plants.

Metal fittings also exhibit varied corrosion resistance. Austenitic stainless steel pipe fittings perform well in fresh water, acidic water, and most soil types. They resist nitric acid and phosphoric acid effectively. However, stainless steel is generally not suitable for hydrochloric acid.

Investigating Polyethylene and PEX for Flexibility

Polyethylene and PEX (cross-linked polyethylene) pipes offer exceptional flexibility. This characteristic significantly simplifies installation. PEX pipes bend around obstacles, reducing the need for numerous joints and fittings. Fewer connections mean fewer potential points of failure, enhancing system reliability. PEX also expands without bursting when frozen, making it suitable for cold climates.

Crimp fittings streamline the process of joining PEX tubing. These fittings provide secure and reliable connections. The crimp ring ensures a tight and correctly positioned connection, preventing leaks. PEX’s cross-linking process enhances its durability and flexibility. This makes it resistant to cracking and breaking under stress. High-quality PEX fittings are made from the same strong material, ensuring consistent performance.

PEX and polyethylene pipe fittings are preferred in several applications:

- Water Distribution Systems: For hot and cold water in residential and commercial settings.

- Radiant Floor Heating Systems: For circulating heated water beneath floors.

- Snow Melting Systems: Employed under driveways and walkways.

- Geothermal Heat Pump Systems: Essential for underground heat exchange.

- Hydronic Heating Systems: For distributing heated water to warm spaces.

Selecting Specialty Materials for Corrosive Environments

Some projects involve extremely harsh conditions. Standard materials, such as common PVC Pipe Fittings, cannot withstand these aggressive environments. Engineers must select specialty materials for highly corrosive applications. These materials offer superior resistance to chemical attack, high temperatures, and extreme pressures.

Several specialized pipe fitting materials exist for these demanding situations:

- Stainless Steel Pipe Fittings: These offer excellent corrosion resistance and strength. Grades like SS 304/316 are common in chemical industries and water systems.

- Duplex Stainless Steel Pipe Fittings: These provide high strength and improved resistance to stress corrosion. Duplex 2205 works well in aggressive environments like offshore platforms.

- Super Duplex Stainless Steel Pipe Fittings: These offer even higher strength and corrosion resistance than Duplex grades. Super Duplex 2750 is ideal for extremely harsh conditions, including seawater desalination.

- Inconel/Incoloy Pipe Fittings: These high-performance materials resist heat, oxidation, and corrosion. Inconel 625 serves aerospace and chemical processing. Incoloy 825 handles corrosive chemicals like sulfuric and phosphoric acids.

- Monel Pipe Fittings: These resist corrosion, especially in marine environments. Monel 400 handles both acidic and alkaline conditions.

- Titanium Pipe Fittings: These offer an exceptional strength-to-weight ratio and corrosion resistance. Titanium Grade 2 suits marine and chemical systems.

The table below details various stainless steel grades and their suitability for corrosive environments:

| Stainless Steel Grade | Key Feature | Suitable for Corrosive Environments? |

|---|---|---|

| 304/304L | General purpose, good welding | Mild environments, many oxidizing acids |

| 316/316L | Molybdenum added, better welding | Chlorides, sulfuric acid (some), marine |

| Duplex (e.g., 2205) | High strength, pitting resistance | Chlorides, sour gas, higher pressure |

| Super Duplex (e.g., 2507) | Higher Cr/Mo/N, excellent PR | Severe chlorides, aggressive acids, offshore |

| Hastelloy C22/C276 | Ni-Cr-Mo superalloys | Extreme acids, mixed oxidizers/reducers |

| Titanium | Excellent corrosion, light | Seawater, strong chlorides, nitric acid |

These materials perform exceptionally well in extreme chemical conditions. For example, Super Duplex Stainless Steel offers enhanced resistance to pitting and stress corrosion cracking in aggressive chloride environments. Nickel alloys like Hastelloy provide unmatched resistance to strong acids and alkalis. Titanium forms a passive oxide layer, resisting oxidizing acids and chlorides. Engineers carefully select these advanced materials to ensure long-term system integrity in the most challenging applications.

Ensuring Proper Sizing and Connection Compatibility

Matching Fitting Size to Pipe Diameter

Correctly matching fitting size to pipe diameter is crucial for system integrity. Incorrect sizing often leads to poor system performance and leaks. Understanding the dimensions of both pipes and fittings ensures a secure fit. Even minor mismatches cause significant problems. Engineers must take adequate measurements and verify compatibility.

Pipe dimensions use several measurement types. Nominal Diameter (DN) represents the general diameter of pipes and accessories. It is an average of outside and inside diameters. DN ensures interchangeability between pipes and fittings. Nominal Pipe Size (NPS) is an inch-based standard for pipe sizing. For DN less than 100mm, specific conversions apply. For DN 100mm or greater, the conversion is approximately DN = 25 * NPS. Pipe Weight Class (WGT) indicates pipe wall thickness, such as STD (standard) or XS (extra strong). These classes handle different fluid pressures.

Understanding Thread Types and Sealing Methods

Various thread types exist for pipe fittings. These include NPT (American Standard Pipe Taper Thread) and BSPT (British Standard Pipe Thread Tapered). NPT threads are common in plumbing, irrigation, and HVAC systems. BSP threads are often used for low-pressure plumbing. NPTF (National Pipe Taper Fuel) threads prevent spiral leakage by controlling the crests and roots of both male and female threads. This ensures a material displacement for a seal. Even with NPTF threads, Teflon tape or liquid is recommended as a lubricant and to fill any voids.

Selecting Appropriate Connection Types

Pipe fittings offer a wide range of connection types. These include threaded, socket weld, butt weld, grooved, compression, solvent weld, push-fit, and press-fit. Solvent welding joins plastic pipes like PVC by partially dissolving the material. This fuses them together at a molecular level. Compression fittings secure connections by squeezing tubing to create a watertight seal. Mechanical connections, such as flanges or threaded pipes, are easily removed and replaced. Flanges provide strong connections for high pressures and large diameter pipes. Threaded pipe is one of the easiest connection types to use. Each connection type offers specific advantages and disadvantages, influencing selection based on project needs.

Verifying Compatibility with Existing Systems

Engineers must verify compatibility when integrating new pipe fittings with existing piping systems. This step prevents future failures and ensures system integrity. Several critical steps guide this process:

- Material Compatibility: Match the fitting material with the piping material and the fluid. This prevents corrosion, degradation, and chemical reactions. For example, PVC works well for cold water, CPVC handles hot and cold water, and copper suits household water. Stainless steel is ideal for high-pressure, high-temperature, or corrosive situations. Brass is suitable for hot water, air, and gas.

- Pipe Size and Fitting Dimensions: Ensure the fitting’s inside or outside diameter precisely matches the pipe size. This avoids leaks or improper connections.

- Pressure and Temperature Ratings: Verify the fitting’s design withstands the system’s pressure and temperature ranges. Exceeding these limits can cause premature failure or catastrophic leaks. Always consult manufacturer specifications.

- Connection Method: Select a connection method suitable for the system design, skill level, and maintenance needs. Common methods include threaded connections for metal pipes, solvent welds for plastic pipes, compression fittings for easy installation, and push-fit options for quick connections.

To ensure compatibility, measure the pipe’s outside diameter. For instance, Flexpipe connectors require the pipe’s outside diameter not to exceed 1.063 inches. Larger diameters may not fit properly. Flexpipe connectors are compatible with various materials like EMT conduits, PVC pipes, and wooden dowels. Creative solutions, such as shims, can enhance compatibility with other pipe materials. This requires innovative thinking for successful implementation.

Material compatibility is crucial for extending a process piping system’s life. It also prevents contamination of the process fluid. The chosen pipe material must be non-reactive with the conveyed fluids. Chemicals, fuels, and even water can be corrosive. This leads to damage, leakage, or rupture. Designers should consult chemical compatibility charts. This ensures the material will not corrode or contaminate the fluid. Additionally, the material must withstand operating requirements. These include pressure and temperature ranges and environmental factors like rain, wind, and UV radiation. Installation details, such as buried pipe, also matter. Key considerations include the pipe material’s pressure-temperature rating, thermal expansion and contraction characteristics, and potential pressure surges or phase changes.

Incompatible pipe fitting systems can lead to significant issues. Environmental stress cracking is one such problem. This occurs when chemical effects and mechanical stress combine, causing pipe failure. This typically involves:

- An initial flaw in the pipe or fitting. This can result from manufacturing, transport damage, or sun exposure.

- Mechanical stress applied during installation. This includes overtightening, incorrect connections, or insufficient support leading to sagging.

- Exposure to an incompatible chemical. This further weakens the material.

Individually, these factors might not cause failure. However, their combination, especially under water pressure, can result in cracks or breaks. For example, ketones like acetone and butanone, and plasticizers found in some caulks, tapes, and gaskets, cause deformation and failure in CPVC pipes.

One significant issue arising from incompatible pipe fitting systems is corrosion, particularly galvanic corrosion. This occurs when dissimilar metals, such as brass and other materials, combine. This leads to the deterioration of the metals and the formation of weak points that can cause leaks.

A primary cause of CPVC pipe failure stems from material incompatibility with common construction materials. Many contractors are often unaware that everyday products can degrade CPVC pipes. These include:

- Caulks

- Cleaners

- Sealants

- Fire stop

- Pipe clamps

- Pipe tape

- Thread sealants

- Waterproofing

- Spray foam

- Oils and lubricants

Incompatible pipe fitting systems can also lead to the degradation of PEX piping. PEX is susceptible to chlorine. PEX manufacturers add sacrificial antioxidants to protect against chlorine. However, these consume over time. Furthermore, these antioxidants can leach into the water or other materials in contact with the PEX. This represents a compatibility issue that can lead to damaging pipe failures.

Best Practices for Installation and Maintenance

Proper installation and consistent maintenance are critical for the long-term success of any piping system. These practices prevent costly failures and ensure optimal performance.

Following Manufacturer’s Installation Guidelines

Project teams must always follow the manufacturer’s specific installation guidelines for pipe fittings. These instructions ensure product compatibility, performance, and warranty coverage. For instance, push-to-connect fittings offer fast, tool-free installation. PEX crimp and expansion fittings provide durable connections. Installers use solvent cement to connect PVC solvent-weld fittings, which are ideal for drainage. Copper press and soldered fittings reliably serve water supply systems. Soldering copper requires clean surfaces, even flux application, and uniform heating. Installers correctly wrap Teflon tape clockwise around male threads. They avoid overtightening fittings to prevent cracks, thread stripping, and leaks. For high-pressure or hot water systems, they use CPVC or copper for dependable performance. Matching the fitting material to the pipe type, such as PVC fittings for PVC pipes, is also essential.

Using Correct Tools and Techniques

Using the correct tools and techniques ensures precise and secure pipe fitting installations. Essential tools include pipe jack stands, pipe alignment tools, pipe cutters, and threading machines. Multi-purpose and adjustable tools offer greater flexibility. Accurate measurement and cutting techniques involve double-checking measurements, clearly marking cutting points, and using precise cutting tools for clean edges. This improves fit-ups and reduces alignment errors. Pipe alignment is crucial for smooth fluid flow and preventing stress on joints. Tools like laser alignment devices and mechanical fit-up clamps enhance precision. Installers use pipe wrenches for gripping and turning pipes and fittings. Plumbers’ tape seals pipe threads and prevents leaks. Pipe benders help bend pipes without kinking. Safety gear, including gloves and eye protection, is always necessary.

Performing Thorough Leak Testing

Thorough leak testing confirms the integrity of newly installed pipe systems. This process prevents future issues and ensures operational safety. First, prepare and select representative pipe samples, fittings, and assemblies according to standards like ISO 13259. Ensure these are defect-free and assembled per manufacturer instructions. Condition samples to standard laboratory conditions for consistent results. Next, install the test assembly into a rig, ensuring airtight or watertight connections. Fill the system with water for hydrostatic testing or air for pneumatic testing as specified. Attach and calibrate measurement devices like pressure gauges. Gradually increase internal pressure to the specified level, avoiding sudden surges. Maintain pressure for the required duration, carefully observing the assembly. After the pressure hold, inspect for leaks, such as water droplets, misting, or pressure drops. Document any failures like leaks, joint separation, or cracks. Repeat tests if necessary and compare results to pass or fail criteria.

Establishing a Regular Inspection Schedule

Establishing a regular inspection schedule ensures the long-term reliability and performance of any pipe fitting system. This proactive approach identifies potential issues early, preventing costly repairs and operational disruptions. A comprehensive inspection plan covers various stages of a project, from delivery to post-installation.

Inspectors begin with delivery inspection checks. They verify that the delivery matches the order. They also confirm pipework and equipment are undamaged and complete. Any issues require immediate reporting with photographic evidence. If materials require storage, storage inspection checks ensure the area is clean, safe, and protects the pipework from damage and dirt.

During construction and before testing, teams conduct installation and pre-commissioning inspection checks. These checks cover pre-installation, maintenance access, and pre-commissioning steps. For instance, before hydrostatic testing, general prerequisite checks are crucial. These include confirming all technical submissions, drawings, method statements, and calibration certificates are in place. Inspectors verify pipework fittings and equipment are rated for pressure testing. They also ensure gauges are correctly installed, joints are exposed, and the system is properly filled and vented. Trained personnel must be present.

A pipework installation checklist confirms proper installation. This includes checking that pipework and ancillaries are installed according to drawings and manufacturer requirements. Inspectors ensure discharge nozzles are correctly oriented and deflectors are positioned. They verify pipework is free of damage, corrosion, and obstructions. They also confirm the system can expand and contract without stress. Proper pitch for drainage and venting is essential. Seismic restraints, supports, and hangers must meet specifications.

For hydrostatic testing, the process involves several steps:

- Raising the system pressure: Slowly increase water pressure in 1 bar / 14.5 psi increments until the required testing pressure is reached.

- Allow the system to stabilize: Once testing pressure is reached, shut off valves and let the system settle for 10 minutes. If pressure drops due to settling, top up the system once.

- Confirm the system is stable: After stabilization, document information on the pressure testing certificate.

- Testing started: Maintain the testing pressure for the period NFPA specifies, monitoring for leaks or pressure loss.

- Completion of testing: If no pressure loss is observed over the required time, the test passes.

Regular inspections and adherence to these detailed checks significantly enhance system durability and operational safety.

Informed pipe fitting selection provides significant long-term benefits. It ensures system durability and prevents costly failures. Matching fittings, such as PVC Pipe Fittings, to specific project needs is crucial for operational integrity. This proactive planning leads to successful and efficient project outcomes. Engineers consistently consider all factors for reliable and high-performing systems. They ensure every component contributes to overall success.

FAQ

What are the primary benefits of using PVC pipe fittings?

PVC pipe fittings offer cost-effectiveness, light weight, and excellent corrosion resistance. They require minimal maintenance. Their versatility makes them suitable for various irrigation and construction projects.

How does one ensure compatibility between new fittings and existing piping systems?

Engineers must match material, size, and pressure ratings. They verify the new fitting’s material suits the existing pipe and fluid. They also confirm the fitting’s dimensions and pressure capacity.

Why is professional installation crucial for pipe fittings?

Professional installation ensures proper sealing and alignment. It prevents leaks and premature system failures. Experts follow manufacturer guidelines, use correct tools, and perform thorough leak testing.

How often should one inspect pipe fitting systems?

Regular inspections are essential. Project managers establish a consistent schedule based on environmental factors and system usage. This proactive approach identifies potential issues early, preventing costly repairs and operational disruptions.

Can UV exposure damage plastic pipe fittings?

Yes, UV radiation significantly impacts plastic pipes like PVC. Prolonged exposure causes color changes, surface cracking, and reduced impact strength. It ultimately decreases the functional lifespan of the fittings.