Selecting the ideal PVC Ball Valves ensures efficient water management in irrigation systems. Users must understand critical factors for valve compatibility and longevity. Incompatible valves cause softening, cracking, or catastrophic brittle failure, leading to significant irrigation problems in Water Supply Systems. Proper selection prevents these issues. Durable Plastic Faucets, with their advantages highlighted in resources like “Top 5 Advantages of Using Plastic Faucets in Outdoor and Garden Environments,” also ensure reliability. HDPE Fittings and PPR Pipe Fittings contribute to overall system integrity.

Key Takeaways

- Understand your irrigation system’s needs, like water flow and pipe size, before choosing a PVC ball valve.

- Match the PVC ball valve’s pressure rating and material type to your system’s demands and water quality.

- Choose the right connection type, handle design, and port size for easy use and efficient water flow.

Understand Your Irrigation System’s Specific Needs

Selecting the correct PVC ball valve begins with a thorough understanding of the irrigation system’s unique requirements. This foundational step ensures optimal performance and longevity for the entire setup.

Determine Required Flow Rate and Pipe Diameter

The flow rate and pipe diameter are critical factors for efficient water distribution. The system needs a specific volume of water to reach all plants effectively. For residential irrigation systems, a stationary sprinkler typically requires about 2-4 GPM at 30-50 psi for effective coverage. Smaller spray zones with four heads might use around 2.9 GPM, while larger zones with nine heads could require 6.3 GPM. Standard spray nozzles operate within a range of 0.18 to 2.7 GPM. For smart sprinkler systems, a minimum water flow of 8 GPM at the source is often necessary for correct and efficient operation.

The pipe’s diameter directly influences its capacity to transport water. A larger diameter increases the cross-sectional area, which reduces water velocity for a given flow and minimizes frictional losses. This leads to higher flow efficiency and consistent irrigation, especially across large fields. Conversely, smaller diameters increase water velocity and friction, reducing flow efficiency and potentially causing uneven water distribution.

- Small-Diameter PVC Pipes (1/2 Inch to 2 Inches): These pipes restrict flow and suit lower flow rates or precise control. They are ideal for residential plumbing or greenhouse irrigation where delicate plants need controlled water flow.

- Medium-Diameter PVC Pipes (2 Inches to 6 Inches): These offer greater capacity and versatility. They find use in municipal water distribution and agricultural irrigation networks for larger fields, ensuring adequate hydration.

- Large-Diameter PVC Pipes (8 Inches to 24 Inches and Above): These are essential for high flow rates and large capacities in industrial and municipal applications. They serve as main water distribution lines across cities, ensuring consistent delivery during peak demand.

Choosing the correct pipe size is crucial for efficient water distribution. Pipes that are too small restrict water flow, leading to inadequate supply. Oversized pipes can cause excessive pressure, potentially damaging fittings. Proper sizing ensures water reaches plants efficiently, optimizes system capacity, and minimizes energy costs for pumping. Common PVC irrigation pipe sizes range from 1-inch for small gardens to 6-inch and larger for extensive agricultural operations and main-line installations. These larger pipes handle significant water volumes. Factors influencing pipe size selection include the water demand of crops, the system layout (drip, sprinkler), the length of water travel (longer distances require larger diameters to reduce friction), and pump capacity. All these factors must align to ensure efficient water delivery and conservation.

Evaluate System Operating Pressure

Understanding the system’s operating pressure is equally important. Different irrigation components, such as sprinklers, drip emitters, and spray nozzles, function optimally within specific pressure ranges. For instance, most drip irrigation systems generally operate best within a pressure range of 20-30 psi. Pressure regulation is crucial because these systems are designed to function optimally within this specific range. For drip lines, the ideal pressure is approximately 20 psi, with an acceptable operating range between 15 to 30 psi. Exceeding or falling below these recommended pressures can lead to inefficient watering, equipment damage, or premature system failure.

Identify Water Source and Quality Considerations

The water source significantly impacts valve selection. Water from a municipal supply typically has consistent quality, but well water or pond water may contain sediments, algae, or other impurities. These contaminants can clog valves, reduce their lifespan, or interfere with their operation. If the water source contains particulates, consider valves designed for such conditions or incorporate filtration systems upstream. Chemical treatments in the water, such as chlorine, can also affect certain PVC materials over time. Understanding the water quality helps in choosing a valve material that resists degradation and ensures reliable performance.

Key Features of PVC Ball Valves and Plastic Faucets

Understand Different PVC Material Types

Standard PVC is a common material for irrigation components. It offers good chemical resistance and durability. However, temperature significantly affects its performance. PVC softens and loses structural integrity above 130°F (54°C) to 140°F (60°C). This can lead to potential leaks and system failures. Specific PVC formulations and valve designs can have varying temperature limits. Users must check these limits for their specific application to ensure proper function.

Match Pressure Rating to System Demands

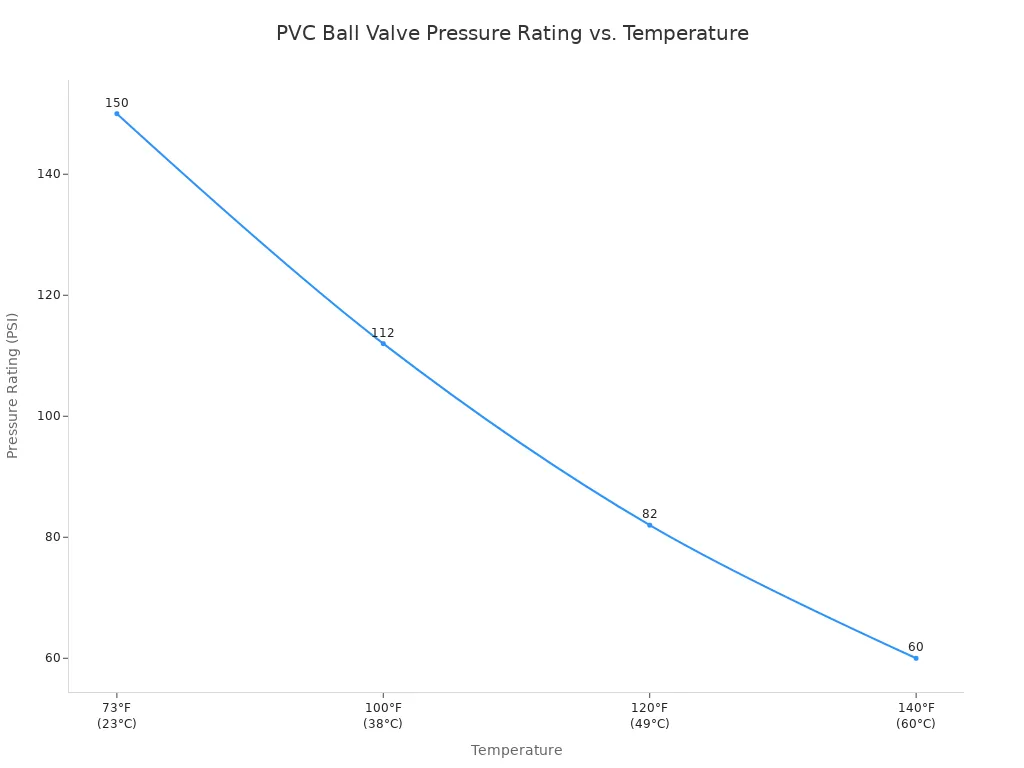

Matching the valve’s pressure rating to the system’s demands is crucial for safety and longevity. A PN10 PVC ball valve operates safely at pressures up to 10 bar (145 psi). A UPVC plastic ball valve with a PN10 rating handles pressures up to 150 PSI. PVC ball valves typically have a maximum pressure rating of 150 PSI at 73°F (23°C). This rating is generally sufficient for common residential irrigation applications.

Pressure ratings decrease as temperature increases.

| Temperature (°F/°C) | Pressure Rating (PSI) |

|---|---|

| 73°F (23°C) | 150 |

| 100°F (38°C) | 112 |

| 120°F (49°C) | 82 |

| 140°F (60°C) | 60 |

All PVC ball valves from 1/4 inch to 2 inches often carry a pressure rating of 250 PSI at 70°F under non-shock conditions. Specific series of 4-inch PVC ball valves carry a pressure rating of 235 psi at 70°F under non-shock conditions. This 235 PSI rating applies to sizes ranging from 2-1/2 inches to 4 inches. Exceeding a valve’s pressure rating causes several problems. It can lead to reduced pressure ratings, potential seal degradation, and thermal expansion concerns. There is also a risk of permanent deformation.

| Failure Mode | Common Cause |

|---|---|

| Cracking | Over-tightening, impact, freezing water |

| Handle Breakage | Excessive force, UV exposure |

| Chemical Attack | Incompatible fluid |

| Leaks | Damaged internal seals, improper installation, cracks, debris |

Select the Appropriate Connection Type

Choosing the right connection type ensures a secure and efficient system. Two common types are threaded and slip (glue socket) connections.

- Threaded Connections:

- Pros: They are easy to install and remove for maintenance.

- Cons: They add cost due to precision machining and surface polishing.

- Glue Socket (Slip) Connections:

- Pros: They are very common and easy to install.

- Cons: They create a permanent attachment. Users cannot remove them unless they use true-union socket weld connections.

| Feature | Threaded Connections | Socket (Slip) Connections |

|---|---|---|

| Installation | Quick, no adhesive/welding needed; forgiving for less experienced installers. | Lengthier due to solvent welding; requires higher skill. |

| Seal Strength | Suitable for low-pressure systems; larger sizes (over 4 inches) may leak. | Stronger, more reliable seal due to solvent cement. |

| Disassembly | Easy to disassemble and reassemble for maintenance. | Permanent once cemented, challenging to disassemble. |

| Flow Disruption | N/A | Minimizes flow disruption due to smooth transition. |

| Cost | Inexpensive. | N/A |

Slip connections offer a stronger, more reliable seal due to solvent cement. Threaded connections are inexpensive and easy to disassemble.

Choose the Best Handle Design for Usability

The handle design impacts how easily users operate the valve. Lever handles are ideal for quick and easy manual operation of ball valves. They are especially useful in applications requiring frequent, rapid valve operation. Their simple design allows for quick opening or closing without significant force. T-handles are ergonomic industrial handles. They offer a generous grip area and simple mechanism activation. This helps relieve stress on the user’s joints. T-handles provide enhanced grip and torque. They allow operators to apply greater force with minimal effort. Their ergonomic design offers a comfortable grip, which reduces operator fatigue during repetitive tasks. This makes them beneficial in industrial settings where frequent manual valve adjustments are necessary. Many Plastic Faucets also feature ergonomic handle designs for ease of use. The choice between a lever and a T-handle often depends on the frequency of operation and the required torque. For simple on/off tasks, lever handles on Plastic Faucets are often preferred.

Differentiate Between Full Port and Standard Port

Understanding the port design is essential for flow efficiency. A full port ball valve exhibits low flow resistance. It acts like a straight piece of pipe. This results in very little pressure drop across the valve. Conversely, a standard port ball valve has a narrower flow path. It creates higher resistance to flow. This leads to a larger pressure drop across the valve.

| Feature | Full Port Valve | Standard Port (Reduced) Valve |

|---|---|---|

| Bore Size | Matches pipe’s internal diameter | One nominal size smaller than the pipe |

| Flow Restriction | Essentially none | Minor restriction |

| Pressure Drop | Very low | Slightly higher |

| Flow Efficiency | Maximum | Reduced |

A full port PVC ball valve offers minimal flow restriction. Its bore diameter equals the pipe’s inner diameter. This allows fluid to flow with little change in velocity or pressure. This leads to more efficient flow, reduced energy consumption, and minimized cavitation risk. In contrast, a standard port PVC ball valve has a smaller bore. It restricts fluid flow. This causes a significant reduction in cross-sectional area, an increase in flow velocity, and a substantial pressure drop. This can negatively impact the overall efficiency of a fluid system.

Full port PVC ball valves are critical in applications requiring maximum flow rates or minimal pressure loss. These include main water supply lines and irrigation systems with long runs. A reduced port valve in a large irrigation system could lead to uneven water distribution or insufficient pressure at the furthest sprinklers. This highlights the necessity of full port valves for efficiency. Full-port ball valves are perfect for irrigation systems that require steady water delivery. They provide maximum flow with minimal restriction. A full port PVC ball valve’s design ensures maximum flow capacity. It eliminates turbulence and prevents clogging. This makes it ideal for applications where preserving flow rate and minimizing pressure drop are crucial. This includes bulk fluid transfer and potable water systems. Many Plastic Faucets also use full port designs for optimal water delivery.

Installation, Durability, and Maintenance Insights

Consider Ease of Installation and Compatibility

Proper installation ensures the long-term performance of any PVC ball valve. Installers must provide proper pipe support. Unsupported piping transmits mechanical stresses to the valve. This stress can cause cracks, leaks, or complete valve failure. This is especially critical for quarter-turn valves. Installers must also retighten bolts or union connections. Valves can relax or settle during storage and installation. Failure to retighten connections before startup can lead to leaks. Poor alignment between the pipe and valve also causes problems. Even slight misalignment introduces shear stress. This stress distort valve internals, warps bodies, or damages seals. This is particularly true for thermoplastics like PVC. Axial misalignment and lack of parallelism create undue stress on the valve body and seals. This leads to premature failure and leakage.

Factors Influencing Valve Durability and Lifespan

Several factors influence a PVC ball valve’s durability and lifespan. A high-quality PVC ball valve can last many years, even up to 20 years or more, under normal irrigation conditions. While the PVC body itself can last over 50 years, the seals (EPDM or FPM) and seat (PTFE) are the primary limiting factors. They typically last between 5 to 20 years. UV exposure significantly impacts outdoor plumbing materials. Prolonged sun exposure causes these materials to weaken, lose flexibility, and eventually break down. UV-resistant PVC pipes and fittings are specifically engineered with enhanced UV inhibitors to prevent such damage. This maintains structural integrity even in direct sunlight. Consider applying UV-resistant coatings to extend the lifespan of PVC ball valves exposed to sunlight. Other factors like chemicals, pressure fluctuations, and high temperatures also affect valve longevity.

Understand Maintenance Requirements and Serviceability

Regular checks help identify issues before they become major problems. A valve that gets stuck or will not close completely indicates a problem. This could be due to debris, damaged parts, or improper installation. Leaking at the handle or pipe suggests worn-out seals or packing. These components deteriorate over time. Obvious corrosion on metal parts signals the valve is nearing its lifespan. A sudden decrease in fluid flow can also indicate a failing valve. This might be due to a partially blocked or damaged ball inside. A slow drip from the handle of a PVC ball valve indicates internal failure. This primarily results from the degradation of flexible seals. The O-rings on the stem and the PTFE seats around the ball can harden, shrink, or crack with age. These internal seals are not permanent. Continuous exposure to chemicals, UV light, or repeated opening and closing causes them to become hard and brittle. Many Plastic Faucets also exhibit similar signs of wear.

Selecting the ideal PVC ball valve requires careful consideration of flow rate, pressure, water quality, and valve features. A correctly chosen valve ensures system longevity, optimal performance, and prevents common irrigation problems. Make informed decisions to build a reliable and efficient irrigation system.

FAQ

What is the difference between full port and standard port PVC ball valves?

- Full port valves have a bore matching the pipe’s diameter. They offer minimal flow restriction. Standard port valves have a smaller bore, which slightly restricts flow.

How long can a PVC ball valve last in an irrigation system?

- High-quality PVC ball valves can last 20 years or more. Seals and seats typically last 5 to 20 years, limiting the overall lifespan.

What temperature limits should users consider for PVC ball valves?

- PVC softens and loses integrity above 130°F (54°C) to 140°F (60°C). Always check specific valve temperature limits for your application.