Choosing the right pipe material is crucial for project success. The ideal choice depends on specific application requirements, considering factors like temperature, pressure, and chemical exposure. Understanding the distinctions between UPVC, CPVC, and PPR is vital. Plastic piping now dominates over 60% of new residential construction, including plastic faucets and various HDPE fittings. Many water supply systems rely on these materials. A plastic ball valve manufacturer China often supplies PVC ball valves and PPR pipe fittings.

Key Takeaways

- UPVC pipes work best for cold water and drainage systems. They resist corrosion and cost less.

- CPVC pipes are good for hot water systems. They handle high temperatures and chemicals well.

- PPR pipes are versatile for both hot and cold water. They last a long time and have strong, leak-proof joints.

What are UPVC Pipes and Their Uses?

UPVC Pipe Composition and Key Characteristics

Unplasticized Polyvinyl Chloride, or UPVC, is a rigid and durable plastic material. Its primary component is PVC resin. Manufacturers blend this resin with thermal stabilizers to prevent degradation during processing. They also add flow lubricants to improve material flow and surface finish. Impact modifiers enhance the pipe’s mechanical strength. Fillers like calcium carbonate increase rigidity and reduce costs. Pigments provide color and UV protection. The manufacturing process involves selecting high-quality UPVC resin and blending it with these additives. An extrusion process then heats and melts the mixture, forcing it through a die to shape the pipe. For fittings, an injection molding process is used.

Advantages of UPVC for Cold Water Systems

UPVC offers significant advantages for cold water systems. It provides exceptional corrosion resistance; it never rusts, scales, or corrodes. This maintains water quality and flow characteristics. Its chemically inert composition resists electrochemical reactions and chemical attacks that degrade metal pipes. The smooth interior surface prevents mineral buildup, which eliminates the need for descaling and maintains efficient water flow. UPVC pipes exhibit exceptional resistance to chemical corrosion, remaining unaffected in corrosive environments. This material also boasts exceptional longevity and resists wear and tear.

Limitations of UPVC Pipes

UPVC pipes have specific limitations. Their temperature rating typically ranges from 0°C to 60°C (32°F to 140°F) for standard applications. Performance diminishes as the temperature approaches 60°C, leading to reduced tensile strength and stiffness. Continuous exposure beyond this can cause softening. Standard UPVC fittings are commonly rated for operating pressures up to 150 psi. However, pressure capacity decreases with increasing temperature. For example, a PN16 fitting at 20°C can withstand full pressure, but at 50°C, its pressure tolerance reduces significantly.

Common Applications for UPVC

UPVC pipes find widespread use across various settings. In residential areas, people use them for potable cold water supply, drainage systems, and vent pipes. Commercial applications include HVAC condensate drainage and chemical waste drainage in laboratories. Industrially, UPVC transports various chemicals, acids, and alkalis in chemical processing plants. Agricultural uses include irrigation systems and water supply for livestock. Infrastructure projects utilize UPVC for underground drainage and sewer systems, stormwater management, and cable protection conduits.

What are CPVC Pipes and Their Applications?

CPVC Pipe Composition and Key Characteristics

Chlorinated Polyvinyl Chloride, or CPVC, is a thermoplastic material. It originates from Polyvinyl Chloride (PVC). Manufacturers produce CPVC by chlorinating PVC resin. This process involves a free-radical reaction where chlorine atoms replace hydrogen atoms in the PVC polymer chain. This increases the chlorine content from about 25% in PVC to approximately 40% in CPVC. After chlorination, the product undergoes cooling, washing, and drying to remove impurities. The dried CPVC is then granulated or pelletized for easier handling. This chemical modification gives CPVC enhanced properties.

Advantages of CPVC for Hot Water Systems

CPVC offers significant advantages for hot water systems. Its modification provides higher temperature tolerance and greater chemical resistance compared to regular PVC. CPVC pipes are rated for water temperatures up to 93°C (200°F). This makes them a single-material solution for both hot and cold water lines. CPVC also exhibits superior chemical inertness. It does not react with chlorine-based disinfectants used in municipal water treatment. This prevents corrosion and eliminates the leaching of harmful substances into drinking water. CPVC systems withstand typical residential and commercial water pressures without bursting.

Limitations of CPVC Pipes

CPVC pipes have specific temperature and pressure limitations. They can generally be used safely at temperatures up to 93°C (200°F) for pressure applications. The specific pressure rating depends on pipe size, wall thickness, and temperature. Smaller pipe sizes allow for higher pressure ratings. However, higher temperatures lead to lower pressure ratings. For example, a ½-inch Schedule 80 pipe can handle up to 850 psi at room temperature. At 82°C (180°F), its maximum working pressure rating drops to 210 psi.

Common Applications for CPVC

CPVC pipes find widespread use across various sectors. In residential settings, people use them for safe drinking water, bathroom and kitchen plumbing, and concealed piping. Commercial applications include offices, hotels, hospitals, and apartment complexes. CPVC handles continuous hot water supply in these environments. Industrially, CPVC pipes are built to withstand chemical exposure, aggressive water qualities, and high pressure. They are ideal for process lines, water treatment systems, and chemical effluent handling in manufacturing plants, food and beverage facilities, and laboratories.

What are PPR Pipes and Their Benefits?

PPR Pipe Composition and Key Characteristics

PPR, or Polypropylene Random Copolymer, is a thermoplastic polymer. It forms from a blend of propylene and ethylene. Manufacturers adjust the proportion of ethylene to fine-tune the material’s properties. This provides unique characteristics ideal for piping systems. The primary raw material is Polypropylene Random Copolymer (PP-R). It offers excellent heat, chemical, and stress-crack resistance. Color masterbatch adds distinctive coloring. Stabilizers and antioxidants prevent degradation from UV radiation, oxidation, and environmental stress cracking. The manufacturing process involves several steps. First, raw materials are mixed and melted in an extruder. This forces the mixture through a die to form the pipe shape. Then, a water bath or air-cooling system cools the formed pipe. This stabilizes its shape. Finally, pipes are marked and packaged for shipment.

Advantages of PPR for Residential and Industrial Use

PPR pipes offer significant advantages for both residential and industrial applications. They boast a long lifespan, resisting corrosion, scaling, and chemical reactions. Unlike metal pipes, PPR pipes do not rust or corrode, preventing water contamination. They handle high temperatures, up to 95°C continuously, and high internal pressures. This makes them suitable for hot water and high-pressure systems. Installation is easy because they are lightweight. Heat fusion welding creates seamless, leak-proof joints without threading or soldering. This method results in strong, leak-proof connections, reducing potential failure points. The flexibility of PPR pipes also contributes to their ease of installation. This makes them suitable for underfloor heating systems and various plumbing needs.

Limitations of PPR Pipes

PPR pipes have specific temperature and pressure limitations. The temperature tolerance of PPR pipes relates to the operating pressure. Higher temperatures can reduce the pressure rating of PPR pipes. Therefore, considering both parameters for specific applications is essential. The pressure-holding capacity of PPR pipes can also be influenced by temperature. Manufacturers specify pressure ratings at a certain temperature. Exceeding this temperature may impact overall performance. The maximum operating pressure limit for PPR pipes depends on their service life and the working environment’s temperature. Higher temperatures lead to a lower maximum allowable working pressure.

Common Applications for PPR

PPR pipes find widespread use across various sectors. In residential plumbing, people use them for hot and cold water supply systems. They ensure clean and safe water due to their resistance to scaling and corrosion. PPR pipes are also excellent for hydronic underfloor heating systems. They circulate warm water efficiently due to their high-temperature resistance. In industrial applications, PPR pipes transport chemicals, acids, and other fluids. They require high corrosion resistance and suit high pressure and temperature environments in factories and power plants. Agricultural systems also utilize PPR for irrigation and water systems. They handle large volumes of water without degradation.

How Do UPVC, CPVC, and PPR Compare?

Selecting the appropriate piping material requires a thorough understanding of each option’s performance characteristics. UPVC, CPVC, and PPR each offer distinct advantages. Project managers must evaluate these differences against specific application requirements. This comparison highlights key factors influencing material choice.

Temperature Resistance: UPVC vs. CPVC vs. PPR

Temperature resistance is a critical factor in pipe material selection. Each material performs optimally within a specific temperature range. Exceeding these limits can compromise the pipe’s structural integrity and lifespan.

| Pipe Type | Maximum Operating Temperature |

|---|---|

| UPVC | 140°F (60°C) |

| CPVC | 200°F (93°C) |

| PPR | Not specified in the provided text |

UPVC pipes are suitable for cold water applications. Their maximum operating temperature is 140°F (60°C). Temperatures above this limit can cause softening and reduce the pipe’s pressure capacity. CPVC pipes offer superior heat resistance. They can handle temperatures up to 200°F (93°C). This makes CPVC ideal for hot water distribution systems. PPR pipes also demonstrate high-temperature resistance. They are commonly used in hot water systems, often tolerating continuous temperatures up to 95°C. This broad temperature tolerance makes PPR a versatile choice for various plumbing needs.

Pressure Ratings: Which Material Withstands More?

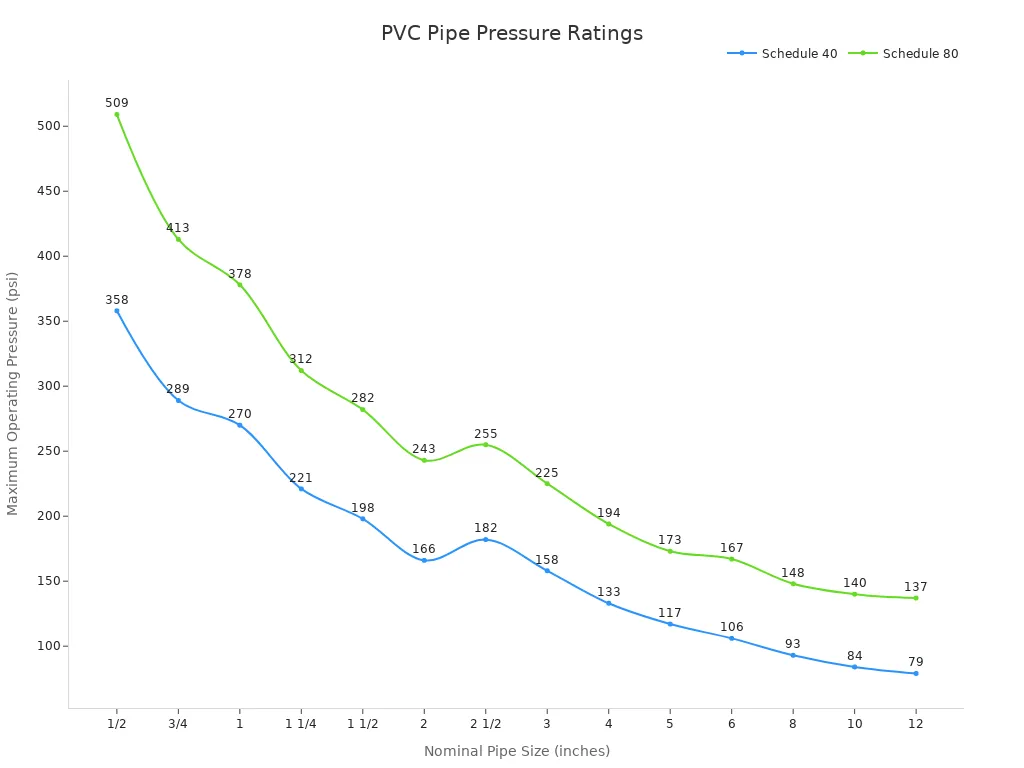

Pressure rating indicates a pipe’s ability to withstand internal pressure without failure. This capacity varies significantly among UPVC, CPVC, and PPR. It also depends on pipe size, wall thickness (schedule), and temperature.

PVC pipes, which share characteristics with UPVC, have specific pressure ratings at standard temperatures. For example, a 1/2-inch Schedule 40 PVC pipe can handle 358 psi at 73°F (23°C). A 1/2-inch Schedule 80 PVC pipe can withstand 509 psi at the same temperature.

| Nominal Pipe Size (inches) | Schedule 40 Maximum Operating Pressure (psi) | Schedule 80 Maximum Operating Pressure (psi) |

|---|---|---|

| 1/2 | 358 | 509 |

| 3/4 | 289 | 413 |

| 1 | 270 | 378 |

| 1 1/4 | 221 | 312 |

| 1 1/2 | 198 | 282 |

| 2 | 166 | 243 |

| 2 1/2 | 182 | 255 |

| 3 | 158 | 225 |

| 4 | 133 | 194 |

| 5 | 117 | 173 |

| 6 | 106 | 167 |

| 8 | 93 | 148 |

| 10 | 84 | 140 |

| 12 | 79 | 137 |

These pressure ratings decrease significantly with increasing temperature. At 140°F (60°C), the strength reduces to approximately 20% of its value at 73°F. CPVC pipes generally offer higher pressure ratings than UPVC, especially at elevated temperatures. Their robust composition allows them to maintain structural integrity under pressure in hot water systems. PPR pipes also exhibit excellent pressure resistance. Their seamless heat-fused joints contribute to the overall system’s strength. Manufacturers specify PPR pressure ratings based on service life and operating temperature. Higher temperatures lead to a lower maximum allowable working pressure for PPR.

Chemical Compatibility: Protecting Your System

Chemical compatibility is crucial for systems transporting various fluids. Each pipe material reacts differently to chemical exposure.

UPVC pipes demonstrate outstanding corrosive resistance and chemical resistance. This makes them suitable for industrial applications involving the transport of acids, alkalis, and other corrosive substances. Their inert nature prevents degradation from chemical attacks. CPVC pipes also possess inherent chemical resistance features. They offer dependability and can withstand high heat and pressure. CPVC eliminates internal and exterior corrosion, which prevents leaks and premature failure. This makes CPVC a reliable choice for aggressive water qualities and chemical process lines. PPR pipes are generally corrosion resistant. They do not react with many common chemicals found in plumbing systems. This property ensures the purity of transported fluids and extends the system’s lifespan.

Installation Methods and Ease of Use

Installation methods vary among these pipe types, impacting project timelines and labor costs.

CPVC pipes are joined using a solvent cement welding process, also known as cold welding. This method requires inexpensive and readily available tools. It does not necessitate heat fusion or other complex techniques. This makes CPVC installation safer, faster, and more plumber-friendly compared to PPR and other pipe types. Installation involves preparation steps. These include wearing protective clothing, wiping away dirt and moisture, inspecting and cutting pipes, and using appropriate tools like sharp circular saws or ratchet cutters for square cuts.

For UPVC pipes, the selection of a connection method depends on specific engineering requirements, pipe material specifications, and economic factors. Various connection methods exist. Each method has its own advantages and disadvantages. This necessitates careful consideration and optimization for practical applications. Regardless of the chosen method, ensuring connection quality meets relevant standards is crucial for the pipeline system’s operation and longevity. Common methods include solvent cementing, threading, and flanging. PPR pipes utilize heat fusion welding. This process involves heating the pipe and fitting ends simultaneously. Workers then join them to create a homogeneous, leak-proof connection. This method eliminates the need for glues or solvents. It results in strong, seamless joints. However, it requires specialized heat fusion tools and trained personnel.

Cost-Effectiveness of Each Pipe Material

The cost-effectiveness of each pipe material involves more than just the initial purchase price. It includes installation costs, maintenance requirements, and expected lifespan.

UPVC pipes generally offer the lowest initial material cost. Their straightforward solvent cement installation also contributes to lower labor costs. This makes UPVC a cost-effective solution for large-scale cold water and drainage projects. CPVC pipes typically have a higher material cost than UPVC. However, their ease of installation with solvent cement can offset some of this initial expense. Their superior temperature and chemical resistance also reduce long-term maintenance and replacement costs, especially in hot water or corrosive environments. PPR pipes often have a higher initial material cost compared to UPVC and CPVC. The heat fusion welding process requires specialized equipment. This can add to the initial setup cost. However, PPR’s long lifespan, resistance to scaling and corrosion, and leak-proof joints contribute to significant long-term savings. These factors reduce maintenance needs and prevent costly repairs over the system’s operational life.

Which Pipe Material is Best for Your Project?

Selecting the optimal pipe material for a project requires careful consideration of various factors. Engineers and project managers must align material properties with specific application demands. This ensures system efficiency, longevity, and cost-effectiveness.

Selecting for Cold Water and Drainage Systems

For cold water supply and drainage systems, UPVC pipes often present the most suitable choice. Their inherent rigidity and resistance to corrosion make them ideal for transporting cold potable water and managing waste. UPVC does not rust or scale, which maintains water quality and consistent flow rates over time. Installers find UPVC easy to work with, and its solvent cement joining method is straightforward. This contributes to lower installation costs. Many cold water systems, including those with plastic faucets, benefit from UPVC’s reliability. Its excellent chemical resistance also makes it a strong candidate for drainage applications where various household or light industrial effluents might be present.

Choosing for Hot Water and High-Pressure Applications

Hot water and high-pressure applications demand materials with superior temperature and pressure resistance. CPVC and PPR pipes are excellent choices for these demanding environments. CPVC handles continuous hot water temperatures up to 93°C (200°F), making it suitable for residential and commercial hot water distribution. PPR pipes also excel in hot water systems, often tolerating continuous temperatures up to 95°C.

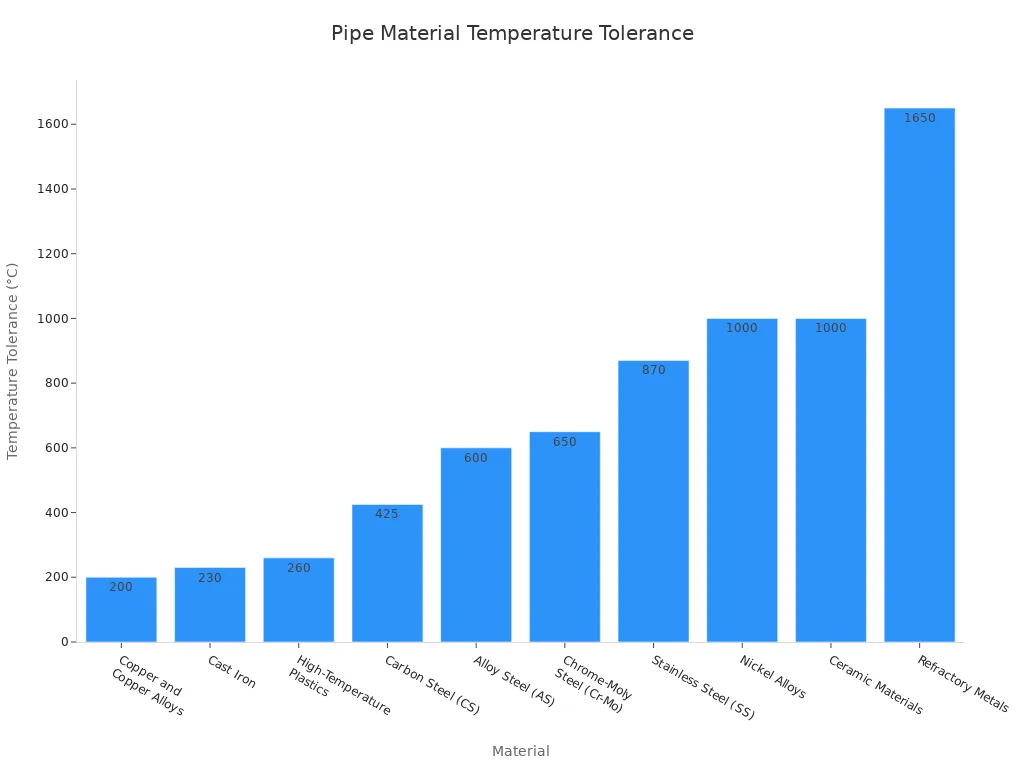

However, for extremely high temperatures and pressures, other materials become necessary. The table below illustrates various materials and their temperature tolerances for such demanding conditions:

| Material | Temperature Tolerance | Applications | Advantages |

|---|---|---|---|

| Carbon Steel (CS) | Up to 425°C (800°F) | General industrial piping, steam, water, oil, gas | Cost-effective, good strength, weldable |

| Alloy Steel (AS) | Up to 600°C (1112°F) | High-pressure steam, power plants, refineries | Improved strength and creep resistance at high temperatures |

| Stainless Steel (SS) | Up to 870°C (1600°F) | Chemical processing, food and beverage, pharmaceutical, corrosive environments | Excellent corrosion resistance, high strength, good for cryogenic applications |

| Chrome-Moly Steel (Cr-Mo) | Up to 650°C (1200°F) | Power generation, petrochemical, high-temperature and high-pressure applications | Excellent creep resistance, good strength at elevated temperatures |

| Nickel Alloys | Up to 1000°C (1832°F) | Aerospace, chemical processing, heat treatment furnaces, extreme corrosive environments | Superior corrosion resistance, high strength at very high temperatures, excellent oxidation resistance |

| High-Temperature Plastics (e.g., PEEK, PTFE) | Up to 260°C (500°F) | Chemical processing, semiconductor, pharmaceutical, food processing | Excellent chemical resistance, lightweight, low friction, good electrical insulation |

| Cast Iron | Up to 230°C (450°F) | Drainage, low-pressure steam, water distribution | Good compressive strength, corrosion resistance in certain environments, vibration dampening |

| Copper and Copper Alloys | Up to 200°C (392°F) | HVAC, plumbing, refrigeration, heat exchangers | Excellent thermal conductivity, corrosion resistance, ductility, antimicrobial properties |

| Refractory Metals (e.g., Tungsten, Molybdenum) | Above 1650°C (3000°F) | High-temperature furnaces, aerospace, nuclear reactors, specialized industrial applications | Extremely high melting points, excellent strength at very high temperatures, good corrosion resistance |

| Ceramic Materials (e.g., Alumina, Silicon Carbide) | Above 1000°C (1832°F) | High-temperature furnaces, aerospace, chemical processing, wear applications | Extremely high temperature resistance, excellent hardness, chemical inertness, wear resistance |

The chart below visually represents the temperature tolerance of various pipe materials, highlighting the broad range of options available for different thermal demands.

For standard residential and commercial hot water systems, CPVC and PPR provide reliable and efficient solutions. They maintain structural integrity under pressure even at elevated temperatures.

Best Materials for Industrial and Chemical Transport

Industrial and chemical transport applications demand pipes with exceptional chemical compatibility and corrosion resistance. The choice of material directly impacts safety and system longevity.

| Material | Corrosive Resistance | Specific Applications |

|---|---|---|

| Stainless Steel | Resists most corrosion, forms protective oxide layer | Oils, some chemicals, water |

| Fluoropolymer (PTFE) Lining | Non-reactive, very resistant against corrosive chemicals | Acid, water, chemicals, oil, universally applicable |

| PVDF Kynar® Lining | Very durable, strong, abrasion-resistant | High-strength acids, chemicals, saltwater, nuclear materials, resists natural sunlight and weathering |

| Resistoflex ATL PTFE Lining | Very strong and durable against saltwater and aggressive chemicals | Paper processing, power generation plants, service industry |

| Polypropylene (PP) Lining | Performs well in saltwater, basic and acidic applications | Water treatment facilities, chemical processing plants, power generation facilities, food and beverage manufacturing |

| Polyvinylidene Fluoride (PVDF) (Lined Pipe) | Withstands corrosive properties of fluids | High-strength acids, chemical processing, electronics manufacturing |

| Fluoropolymer (PTFE) (Lined Pipe) | Strong and corrosion-resistant | Many industrial applications, high temperatures and pressures |

| Polypropylene (PP) (Lined Pipe) | Best for basic fluids with low chemical makeup and low to no corrosive qualities | Small-scale operations, average temperature liquids |

UPVC offers strong resistance to many acids and alkalis, making it suitable for various chemical processing lines. CPVC provides even greater chemical inertness, especially in aggressive water qualities or when transporting harsh chemicals at higher temperatures. PPR pipes are also generally corrosion-resistant and do not react with many common chemicals. For highly corrosive or specialized industrial fluids, lined pipes such as Fluoropolymer (PTFE) or PVDF Kynar® offer superior protection. These materials ensure the integrity of the transported chemicals and prevent system degradation.

Considerations for Plastic Faucets and Fittings

The selection of plastic faucets and fittings plays a crucial role in the overall performance and aesthetics of a plumbing system. While pipes form the backbone, the quality and compatibility of plastic faucets and other connection components are equally important. For cold water systems, UPVC fittings and plastic faucets are common due to their durability and cost-effectiveness. In hot water applications, CPVC or PPR fittings, along with compatible plastic faucets, ensure the entire system withstands elevated temperatures and pressures. Manufacturers design these plastic faucets and fittings to integrate seamlessly with their respective pipe materials, creating a cohesive and leak-proof system. Choosing high-quality plastic faucets and fittings prevents weak points in the plumbing infrastructure. Many modern homes feature stylish and functional plastic faucets in kitchens and bathrooms.

Durability and Lifespan Expectations

Understanding the expected lifespan of piping materials helps in long-term project planning and cost analysis. Each material offers distinct durability characteristics.

| Pipe Type | Expected Lifespan |

|---|---|

| PPR | 50 to 100 years |

| CPVC | Minimum of 50 years |

| UPVC | Not specified in the provided text |

PPR pipes boast an impressive expected lifespan, ranging from 50 to 100 years. This longevity makes them a highly durable choice for both residential and industrial applications. CPVC pipes also offer excellent durability, with a minimum expected lifespan of 50 years. Their resistance to corrosion and high temperatures contributes to this extended service life. While the specific lifespan for UPVC is not detailed in the provided data, its known resistance to corrosion and chemical degradation suggests a long service life in appropriate cold water and drainage applications. The durability of plastic faucets and other components should also align with the pipe’s lifespan to ensure a consistently reliable system.

The optimal pipe material is always application-specific. UPVC excels in cold water and drainage systems. CPVC performs best in hot water applications. PPR offers great versatility for both residential and industrial uses. Always consult project specifications. Also, check local building codes for the final selection.

FAQ

What is the maximum temperature for UPVC pipes?

UPVC pipes have a maximum operating temperature of 140°F (60°C). Higher temperatures can cause softening and reduce the pipe’s pressure capacity.

Which pipe material is best for residential hot water?

CPVC and PPR pipes are excellent choices for residential hot water systems. They handle continuous high temperatures effectively. 🌡️

How do installers connect these plastic pipes?

Installers join UPVC and CPVC pipes using solvent cement. PPR pipes utilize heat fusion welding. This creates strong, leak-proof connections.