Identifying the best Ball Valves and plastic valves is essential for successful plumbing and irrigation projects. Project managers often consider how to choose valves for water piping to ensure system integrity. They must select durable and cost-effective options for long-term reliability. Understanding what valve types should I use for irrigation is crucial for optimal performance. For example, plastic ball valves offer excellent corrosion resistance. Proper selection of Ball Valves, including specific ball valves for irrigation, guarantees ease of maintenance, especially when integrating with PVC Pipe Fittings.

Key Takeaways

- Choose the right valve material. It ensures your system lasts a long time. Consider what liquids or gases will flow through it.

- Understand pressure, temperature, and flow rate needs. Valves must work well within these limits. This prevents problems.

- Ball valves offer quick control. They provide a tight seal. This makes them good for many plumbing and irrigation uses.

- Plastic valves resist rust and chemicals. They are light and easy to install. This makes them good for many projects.

- Install valves correctly. Follow sealing and orientation rules. This prevents leaks and ensures the system works well.

Essential Criteria for Valve Selection

Material Durability and Chemical Compatibility

Selecting the right valve material ensures long-term system integrity. Material composition directly impacts a valve’s durability and its ability to withstand various media. Brass ball valves are robust. They handle high pressures up to 55 bar (798 psi) and temperatures up to 160 °C (320 °F). These valves suit neutral and noncorrosive media like water and compressed air. Stainless steel ball valves offer superior durability. They resist leaks in high-temperature (up to 220 °C/428 °F) and high-pressure (up to 70 bar/1015 psi) environments. Stainless steel also provides excellent corrosion resistance, making it ideal for demanding conditions. Cast iron ball valves are robust for heavy-duty use. They withstand up to 40 bar (580 psi) and 120 °C (248 °F).

Chemical compatibility is equally vital. Valves must resist external elements and the liquids or gases flowing through them. Plastic valves are often preferred over metallic options for irrigation. They resist rust and harsh chemicals. Chlorinated polyvinyl chloride (CPVC) handles corrosive liquids up to 100 degrees Celsius. Polypropylene offers high resistance against chemicals and provides high impact strength. Plastic valves are highly resistant to acids, bases, salt solutions, and organic solvents.

Pressure, Temperature, and Flow Rate Requirements

Understanding pressure, temperature, and flow rate requirements is crucial for valve performance. Valves must operate effectively within a system’s specific parameters. Standard brass ball valves, common in residential plumbing, typically handle pressures up to 600 PSI. For home plumbing, a typical working pressure range is 150-300 PSI. Residential and light commercial brass ball valves often have pressure ratings of 150 psi, 200 psi, or 300 psi. The PN (Pressure Nominal) system also specifies ratings, such as PN16 (16 bar or 232 psi) for residential systems. Temperature limits prevent material degradation and ensure safe operation. Flow rate considerations ensure efficient fluid movement without excessive pressure drop.

Installation Simplicity and Maintenance Needs

Ease of installation and maintenance significantly impacts project costs and long-term system reliability. Simple valve designs reduce labor time and complexity. Plumbers typically charge between $45 to $200 per hour for valve replacement. A simple replacement might take one to two hours. Jobs involving hard-to-access valves can take several hours. For example, replacing a main water line valve costs $200–$400. This involves shutting off the entire house water supply. Ball valves have a simpler design. They are quick to install, making them cheaper to replace. Replacing a ball valve can cost as low as $200. Globe valves, with more components, are more labor-intensive. They can cost between $150 to $350 to replace. Regular maintenance also extends valve lifespan. Easy access for inspection and repair minimizes downtime and future expenses.

Cost-Effectiveness and Long-Term Value

Project managers always consider cost-effectiveness when selecting valves. The initial purchase price often influences decisions. However, true value extends beyond this upfront expense. Durable materials like stainless steel or high-grade plastics offer significant long-term savings. These materials resist corrosion and wear, reducing the need for frequent replacements. Cheaper valves may require more maintenance or fail prematurely. This leads to higher overall costs due to repairs, downtime, and labor. Investing in quality valves from the start minimizes future expenditures. It ensures reliable system operation for many years. Consider the total cost of ownership, not just the sticker price.

Understanding Valve Certifications and Standards

Valve certifications and standards guarantee product quality and safety. These certifications ensure valves meet specific performance criteria. For instance, NSF International certifies products for public health and safety. NSF/ANSI 61 certification indicates a valve is safe for potable water applications. ASTM International develops technical standards for materials, products, systems, and services. These standards ensure material consistency and performance. ISO (International Organization for Standardization) provides global industrial and commercial standards. Adhering to these standards ensures compatibility and reliability across different systems. Always check for relevant certifications. They confirm a valve’s suitability for its intended use. This protects both the project and its users.

Understanding Ball Valves for Plumbing & Irrigation

How Ball Valves Regulate Flow

Ball valves are a type of quarter-turn valve. They operate by rotating 90 degrees to either open or close the flow of liquid or gas. This simple motion gives them the ‘quarter-turn’ designation. A ball valve uses a rotating ball with a bore, or flow passage, through its center. Turning this ball one quarter-turn stops the flow. This design allows for quick and efficient control over fluid movement.

Advantages of Using Ball Valves

Ball valves offer several key advantages for plumbing and irrigation projects. They provide a tight seal, which reliably reduces the risk of leaks. This excellent shut-off capability minimizes leakage. Their sealing mechanism ensures a secure closure. This makes them ideal for critical systems where leak prevention is paramount. While standard ball valves have restricted flow control, specialized V-port ball valves offer precise flow control. These valves feature a V-notch or contoured shape on the ball. This design provides an equal percentage flow characteristic. It allows for stable and precise flow control. They combine precise control with the durability and reliability of other ball valves. They also retain advantages like leak-tight sealing and quick operation.

Common Applications for Ball Valves in Plumbing and Irrigation

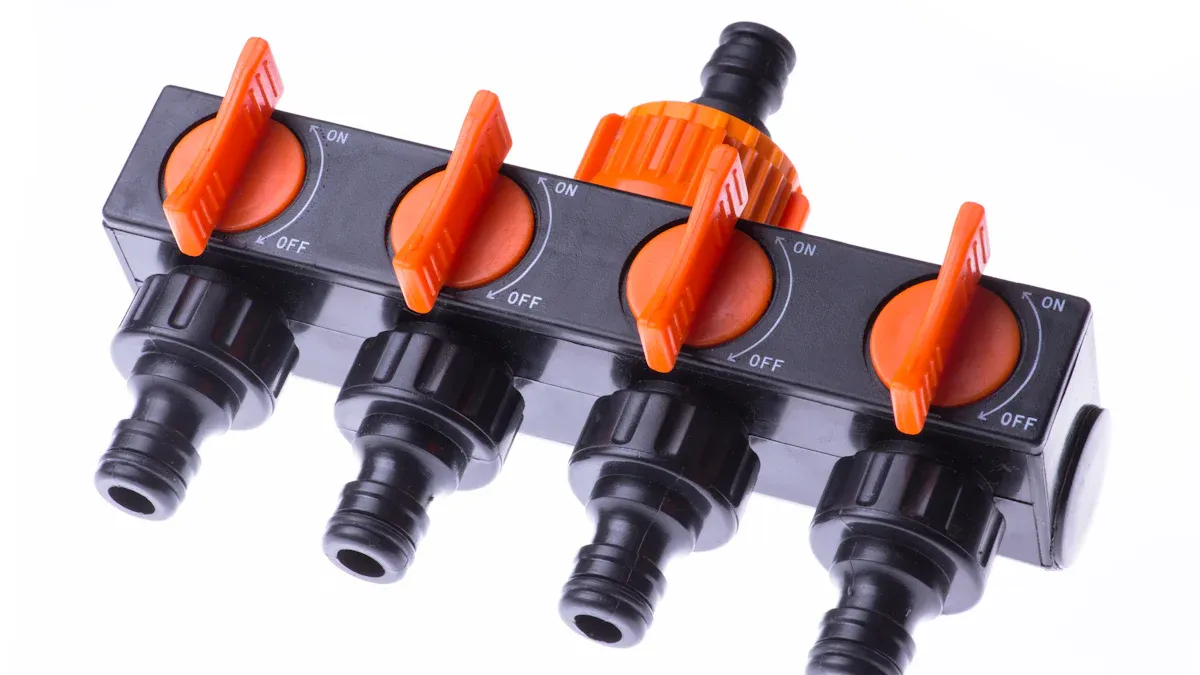

Ball valves are versatile components in many systems. In plumbing, people use them as shut-off valves for water lines, water heaters, and outdoor faucets. Their quick operation makes them useful for emergency shut-offs. For irrigation, ball valves control water flow to different zones or sections. They are common in sprinkler systems and drip irrigation setups. People also use them in industrial applications for controlling various fluids and gases. Their robust design and reliable performance make them a preferred choice for many demanding environments.

Understanding Plastic Valves for Plumbing & Irrigation

Types of Plastic Materials Used in Valves

Plastic valves play a crucial role in modern plumbing and irrigation systems. Manufacturers commonly use several types of plastic materials for these valves. These include Polyvinyl chloride (PVC), Polypropylene (PP), and Polyethylene (PE). Each material offers distinct properties suitable for various applications. Irrigation system designers increasingly choose composite (polymer) material components for irrigation control valves. These high-tech composite materials offer significant benefits. They provide cost efficiency, easy installation and maintenance, chemical resistance, and cavitation resistance.

Benefits of Choosing Plastic Valves

Choosing plastic valves offers numerous advantages for plumbing and irrigation projects. They provide superior resistance to corrosion from chemicals, unlike metal valves. This ensures long-term durability and reduces maintenance needs. Plastic valves are also highly versatile. They effectively regulate liquid flow without leakage in residential plumbing systems. Their lightweight nature simplifies installation and reduces shipping costs. This makes them an economical choice.

Plastic ball valves, for instance, are highly resistant to corrosion, rust, and chemical damage. This ensures a longer lifespan and reduces replacement needs. They are significantly lighter than metal valves, simplifying handling and installation, especially in tight spaces. Their simple design offers easy on/off control with minimal wear and tear, reducing leak risks and requiring little maintenance. PVC valves are also an environmentally friendly option because PVC is a recyclable material.

Ideal Applications for Plastic Valves, including with PVC Pipe Fittings

Plastic valves are ideal for many applications due to their unique properties. Their excellent chemical resistance makes them suitable for systems handling corrosive fluids, such as in chemical processing or water treatment plants. In irrigation, plastic valves control water flow to different zones, especially in agricultural and landscape settings. Their lightweight and easy-to-install nature makes them perfect for residential plumbing, including connections with PVC Pipe Fittings. They are also widely used in swimming pool and spa systems, where resistance to chlorine and other chemicals is essential. Plastic valves offer a reliable and cost-effective solution for many fluid control needs.

Top 5 Ball Valves for Plumbing & Irrigation Projects

Full Port Brass Ball Valves for High Flow

Full port brass ball valves are a top choice for systems demanding maximum flow efficiency. Their design features an internal bore matching the pipe diameter. This minimizes flow restriction and pressure drop. Consequently, these valves are ideal for applications requiring high flow rates. They ensure fluids move through the system with minimal impedance. Red-White Valve Corp. maintains a strong presence in the plumbing and commercial markets with their brass full port ball valves. These valves find common use in various commercial plumbing applications. They are essential components in HVAC systems, managing heating, ventilation, and air conditioning. They also serve critical functions in hot water supply lines, ensuring efficient delivery.

Stainless Steel Ball Valves for Durability

Stainless steel ball valves offer exceptional durability and corrosion resistance, making them suitable for demanding environments. Stainless steel is renowned for its superior corrosion resistance. Chromium forms a protective passive oxide layer on its surface. This property makes stainless steel ball valves highly suitable for corrosive marine environments. Specifically, 316 stainless steel includes 2% molybdenum. This significantly improves its corrosion resistance, particularly in marine settings. These valves are crucial for handling high pressures and extreme temperatures in marine applications like desalination plants. The material’s excellent corrosion resistance makes it ideal for the corrosive nature of seawater. It ensures reliable performance in saltwater environments, including desalination and offshore platforms. 316 stainless steel contains molybdenum, which boosts its resistance to pitting and crevice corrosion in chloride-containing conditions. This makes it a preferred choice for marine applications. Stainless steel ball valves can withstand corrosive media such as acids, alkalis, and saltwater. They effectively resist saltwater corrosion in marine settings.

PVC Compact Ball Valves for General Use

PVC compact ball valves offer a cost-effective and reliable solution for many general plumbing and irrigation needs. These valves are lightweight and easy to install. However, users must understand their pressure and temperature limitations. The stated pressure limit for PVC compact ball valves applies to static, non-shock pressure. This limit does not account for dynamic forces such as water hammer. Water hammer can cause sudden pressure surges significantly exceeding the valve’s rated capacity. For instance, a system operating at 60 PSI could experience spikes of up to 600 PSI due to water hammer. Standard PVC ball valves cannot withstand such forces. To prevent failures, users should close valves slowly.

The overall pressure capacity of a system using PVC compact ball valves is limited by its weakest component. For example, if a Schedule 80 valve, rated for 240 PSI, is installed on a Schedule 40 pipe, typically rated for 140 PSI, the system’s maximum safe pressure remains 140 PSI. Therefore, considering the pressure ratings of all components—pipes, fittings, and valves—is crucial. Design the system around the lowest-rated part.

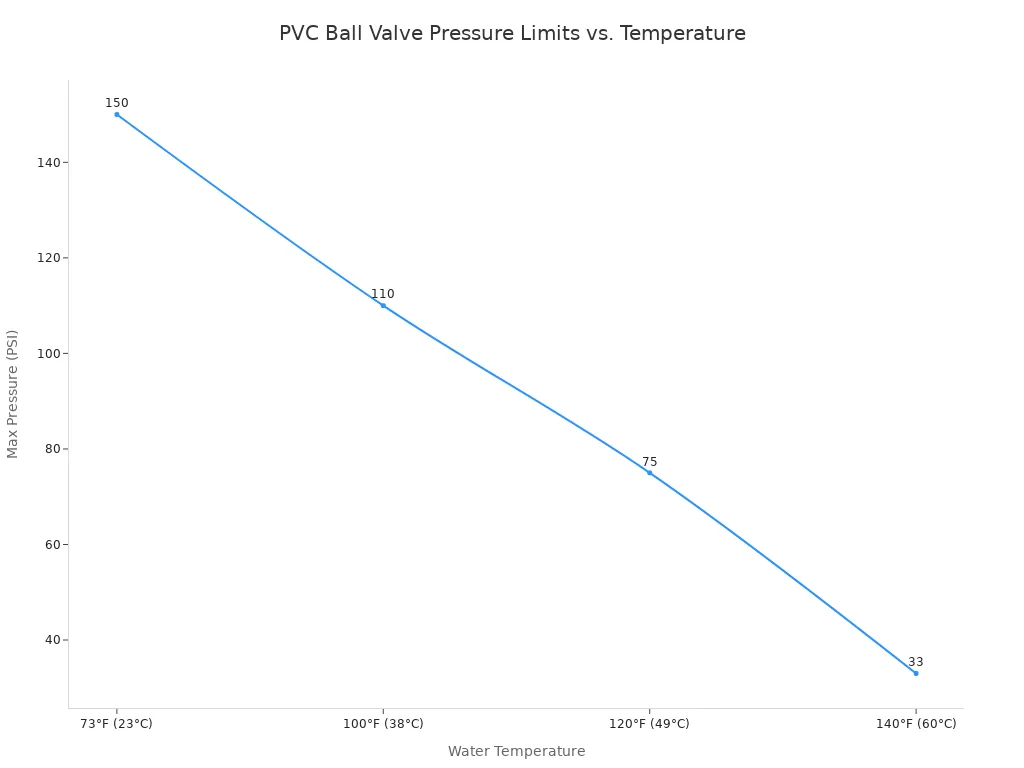

The maximum pressure a PVC compact ball valve can handle decreases significantly as water temperature increases.

| Water Temperature | Max Pressure (for a 150 PSI Valve) |

|---|---|

| 73°F (23°C) | 150 PSI |

| 100°F (38°C) | ~110 PSI |

| 120°F (49°C) | ~75 PSI |

| 140°F (60°C) | ~33 PSI |

This chart illustrates how temperature impacts pressure ratings. Always consider both factors for safe and effective system operation.

CPVC Ball Valves for Hot Water Applications

CPVC ball valves are an excellent choice for hot water applications. Manufacturers design these valves to handle higher temperatures and pressures than standard PVC. CPVC material resists corrosion and chemical degradation. This makes CPVC valves suitable for residential and commercial hot water systems. They maintain structural integrity even with continuous exposure to hot water. CPVC valves are also lightweight. This simplifies installation. Their smooth interior surfaces prevent scale buildup. This ensures consistent flow rates over time.

CPVC ball valves typically operate at temperatures up to 200°F (93°C). They also handle pressures up to 100 PSI at these elevated temperatures. This makes them ideal for hot water lines, hydronic heating systems, and industrial processes involving heated fluids. Their robust construction ensures reliable performance in demanding environments.

PEX Ball Valves for Flexible Piping Systems

PEX ball valves are specifically designed for use with flexible PEX piping systems. PEX (cross-linked polyethylene) piping has gained popularity due to its flexibility, durability, and ease of installation. PEX ball valves integrate seamlessly with these systems. They provide reliable shut-off control. These valves are available in various connection types, including crimp, clamp, and push-to-connect. This offers versatility for different installation methods.

PEX ball valves resist corrosion and scale buildup. This ensures a long service life. Their design allows for quick and secure connections to PEX tubing. This reduces installation time and labor costs. PEX systems, including their valves, can expand and contract with temperature changes. This minimizes the risk of bursting pipes in freezing conditions. PEX ball valves are commonly used in residential plumbing for hot and cold water distribution. They also find applications in radiant floor heating systems. Their flexibility and ease of use make them a preferred choice for modern plumbing projects.

Top 5 Plastic Valves for Plumbing & Irrigation Projects

Plastic valves offer distinct advantages for many plumbing and irrigation systems. Their unique material properties make them ideal for specific applications where metal valves might corrode or prove less cost-effective. This section explores five top plastic valve types, highlighting their benefits and ideal uses.

PVC True Union Ball Valves for Easy Maintenance

PVC true union ball valves stand out for their exceptional ease of maintenance. This design allows for complete valve removal without cutting pipes. This feature proves particularly beneficial for systems requiring frequent cleaning, inspection, or part replacement. Unlike traditional ball valves, true union models incorporate replaceable parts and enable hassle-free servicing. This minimizes downtime and improves system efficiency. The union ends also facilitate easy disassembly, making it simple to clean, inspect, or replace internal components without disturbing the surrounding piping.

The true union design offers significant advantages:

- True Union Design: This allows users to remove the valve body from the pipeline without cutting pipes. This simplifies maintenance, cleaning, inspection, and replacement. It also means the entire system does not need a shutdown for servicing.

- Modularity: The modular construction enables users to upgrade or change parts without replacing the entire valve. Components can be replaced without removing the whole valve, saving time and labor. It also supports quick disassembly and reassembly.

- Quick-Disconnect Feature: This feature facilitates rapid maintenance or replacement, significantly reducing downtime. For example, it can reduce maintenance time by about 73% compared to traditional valves, taking only 8 to 12 minutes.

- Replaceable Parts: The design allows for easy replacement of internal components. This minimizes downtime and maximizes system efficiency.

PP (Polypropylene) Ball Valves for Chemical Resistance

Polypropylene (PP) ball valves are highly valued in industrial fluid handling due to their robust chemical resistance and high tensile strength. This makes them suitable for applications like chemical tanks, pipes, and Returnable Transport Packaging (RTP). Polypropylene generally exhibits superior chemical resistance compared to polyethylene. It effectively resists many organic solvents, acids, and alkalis. However, it is susceptible to attack from oxidizing acids, chlorinated hydrocarbons, and aromatic solvents. Rapid swelling occurs in the latter two.

For liquid cleaning processes, polypropylene is an ideal material, particularly for aqueous parts washing. Here, baskets are submerged in non-oxidizing agents for extended periods. Its impermeability ensures complete protection of coated baskets from cleaning solutions. Furthermore, its density makes it nearly impervious to water, making it excellent for sealing against liquids, provided internal temperatures do not exceed 180°F. Users must avoid using polypropylene in processes involving oxidizing acids, chlorinated hydrocarbons (such as trichloroethylene), and aromatic solvents. The material rapidly swells when exposed to chlorinated and aromatic solvents.

ABS Ball Valves for Cold Water Applications

ABS (Acrylonitrile-Butadiene-Styrene) ball valves are an excellent choice for cold water applications. ABS material, specifically ABS-DWV, has proven satisfactory for use across a wide temperature span. This range extends from -40°F to 180°F. This broad temperature capability includes cold water applications, indicating its suitability for such conditions. ABS valves offer good impact strength and rigidity, making them durable in various plumbing and irrigation setups. They are often used in drain, waste, and vent (DWV) systems, as well as in general cold water lines where their robust nature and temperature tolerance are beneficial. Their smooth interior surfaces also help maintain consistent flow rates and resist scale buildup.

PVDF Ball Valves for High Purity Systems

PVDF (Polyvinylidene Fluoride) ball valves are critical components in systems demanding the highest levels of purity. Manufacturers design these valves specifically for applications where fluid integrity is paramount. PVDF offers exceptional chemical resistance and thermal stability. It does not leach contaminants into the fluid stream. This makes PVDF an ideal material for handling ultra-pure water, aggressive chemicals, and sensitive media.

PVDF ball valves find extensive use in several specialized industries. Food processing systems rely on them for strict cleanliness. These valves prevent contamination and maintain product quality. Pharmaceutical manufacturing also considers them essential. They help maintain contaminant-free environments. This prevents quality issues from even the slightest impurities. In drinking water treatment, PVDF ball valves precisely control water flow in filtration systems. This ensures effective impurity retention. They also stably open and close in disinfection systems for precise disinfectant dispensing. Seawater desalination, particularly reverse osmosis systems, also benefits from PVDF valves. These valves withstand high salt environments and assist in freshwater production.

The material properties of PVDF are crucial for these high-purity applications. High-purity valves must resist corrosion from both the media and the environment. This ensures excellent performance regardless of flow conditions. The valve materials must also exhibit strong chemical compatibility. They must not react with service fluids. They also must not leach chemicals into the fluid stream. This could compromise fluid integrity. PVDF meets these stringent requirements. It provides reliable and consistent performance in the most demanding high-purity environments.

Polyethylene (PE) Ball Valves for Outdoor and Irrigation Use

Polyethylene (PE) ball valves offer a robust and cost-effective solution for outdoor and irrigation projects. Their inherent flexibility, impact resistance, and excellent chemical resistance make them well-suited for agricultural, landscape, and residential irrigation systems. PE valves integrate seamlessly with PE piping, creating a durable and leak-resistant system.

PE ball valves demonstrate excellent longevity. They withstand environmental stresses such as UV radiation and extreme weather conditions. This makes them a reliable choice for outdoor installations. PE ball valves exhibit resistance to UV degradation and weathering. This ensures their long-term reliability in outdoor environments, particularly in agricultural irrigation systems. However, prolonged exposure to ultraviolet (UV) light can degrade PE material over time. Therefore, for outdoor applications, using UV-stabilized PE or protective coverings is advisable. This helps extend the valve’s lifespan and maintain its performance. Their lightweight nature also simplifies installation in large-scale irrigation networks. This reduces labor and equipment costs.

Best Practices for Valve Installation and PVC Pipe Fittings

Proper valve installation ensures system longevity and prevents costly issues. Careful attention to detail during this process minimizes leaks and optimizes performance. Following established best practices helps achieve reliable plumbing and irrigation systems.

Proper Sealing Techniques for Leak Prevention

Effective sealing is crucial for preventing leaks in any plumbing system. When working with threaded PVC Pipe Fittings, installers commonly use specific compounds. Plumber’s tape, also known as Teflon tape or thread sealant tape, provides an excellent seal. Pipe joint compound, often called pipe dope or thread sealant paste, offers another reliable option. For larger diameter pipes or high-pressure systems, using both pipe joint compound and thread sealant tape together often provides the best results. These sealants should be non-hardening and compatible with the plastic material. They must not contain lubricants that promote overtightening, which can damage fittings. Anaerobic resin compounds also offer longer-lasting seals, but they require correct chemistry matching for plastic fittings.

Correct Valve Orientation and Flow Direction

Installing valves with the correct orientation is vital for proper system function. Many valves, especially check valves, have a specific flow direction. Installers must always observe the flow arrow marked on the valve body. Installing a check valve backward, for instance, will completely block the flow when the pump is running. This incorrect installation can potentially damage the pump and the entire system. Proper orientation ensures the valve operates as intended, allowing fluid to move in the correct direction and preventing backflow where necessary.

Essential Tools and Equipment for Installation

Successful valve installation requires the right tools and equipment. Installers typically use pipe wrenches or channel locks to tighten threaded connections. For cutting pipes, they employ pipe cutters designed for the specific material, such as PVC or PEX. Measuring tape ensures accurate pipe lengths. Deburring tools smooth cut edges, preventing damage to seals. A clean rag helps prepare surfaces for sealing compounds. Having these essential tools readily available streamlines the installation process and helps achieve secure, leak-free connections.

Maintaining Your Valves for Extended Lifespan

Proper valve maintenance extends the life of plumbing and irrigation systems. Regular care prevents costly repairs and ensures efficient operation. Users can achieve long-term reliability with consistent attention.

Establishing a Regular Inspection Schedule

Regular inspections help identify potential problems early. System operators should check valves for visible signs of wear, corrosion, or leaks. They must also listen for unusual noises during operation. A consistent schedule prevents minor issues from becoming major failures. This proactive approach saves time and money.

Cleaning and Lubrication for Optimal Performance

Cleaning and proper lubrication are vital for valve function. Users should clean external valve surfaces to prevent dirt buildup. Lubricating internal components ensures smooth operation. For O-rings in plastic ball valves used with potable water, silicone-based lubricants are highly recommended. These lubricants offer excellent friction reduction and waterproof properties. They also provide high-temperature stability and low-temperature fluidity. Ester-based lubricants offer safe and biodegradable alternatives. Both silicone and ester-based lubricants are safe for use and do not pose health risks or contamination. For example, Fuchs® Silicone Compound (BOSHART PART NUMBER “OR-LUBE”) holds NSF 61 certification for potable water systems. Plumber’s Faucet And Valve Grease (SKU: J40196) is another non-toxic, waterproof silicone lubricant safe for all potable water systems. It assists in installing faucet spouts, O-rings, and stem repair kits. Hercules® Plumber’s Silicone Grease is also a high-performance, silicone-based lubricant safe for potable water systems. It lubricates O-rings, faucets, and valve stems. Users should avoid petroleum-based greases for rubber and plastic components. These greases can degrade materials over time.

Troubleshooting Common Valve Issues

Users can resolve many common valve issues with simple troubleshooting steps. A leaking stem often indicates a problem.

| Common Causes of Leaking Stem | Resolution Methods |

|---|---|

| Stem packing failure | Replace the stem packing and other damaged components. |

| Bent or misaligned stem | Replace the stem packing and other damaged components. |

| Stem nut or bolt failure | Tighten the stem nut or bolt; replace if damaged. |

| Improper lubrication | Lubricate the ball valve regularly. |

| Corrosion | Use corrosion-resistant materials; replace corroded components. |

| Operating conditions (high pressure/temperature) | Use a valve with a stronger stem or higher pressure rating. |

| Stem blockage due to debris | Clean the stem and ensure proper rotation. |

Failing valve seats also present clear signs. These include fluctuating pressure, which indicates improper sealing. Steady flow but low pressure suggests valve degradation. Squeaking or rattling noises often point to friction between the ball and valve seat. Grinding noises typically signal internal damage or wear. Damaged valve seats degrade over time due to pressure, heat, or chemical exposure. This leads to inconsistent flow and pressure.

Making informed valve choices ensures successful plumbing and irrigation projects. Project managers must balance performance, cost, and durability in their selections. Investing in high-quality valves guarantees long-lasting and efficient systems. They provide reliable solutions for various applications. Prioritize material compatibility and proper installation for optimal results. This approach leads to robust and dependable fluid control systems.

FAQ

What is the main difference between ball valves and plastic valves?

Ball valves describe a flow control mechanism. They use a rotating ball. Plastic valves refer to the material. They are made from plastic. Both types offer specific advantages depending on the application.

Why are CPVC ball valves suitable for hot water applications?

CPVC ball valves handle higher temperatures and pressures than standard PVC. Their material resists corrosion and chemical degradation. This makes them ideal for residential and commercial hot water systems.

When should one choose stainless steel ball valves for a project?

Choose stainless steel ball valves for demanding environments. They offer exceptional durability and corrosion resistance. They perform well in high-pressure, high-temperature, and corrosive marine settings.

What makes PVC true union ball valves easy to maintain?

PVC true union ball valves allow complete valve removal without cutting pipes. This design simplifies cleaning, inspection, and part replacement. It minimizes downtime and improves system efficiency.

Are ABS ball valves suitable for hot water systems?

ABS ball valves are best for cold water applications. Their material handles temperatures from -40°F to 180°F. However, they are primarily used in drain, waste, and vent (DWV) systems and general cold water lines.