Securing the best prices for UPVC plumbing valves from Chinese manufacturers requires strategic sourcing. This guide provides actionable steps for cost-effective procurement and quality assurance. The broader UPVC injector market, which includes various plastic pipes, demonstrates robust growth. Experts project this market to expand from USD 1.2 billion in 2024 to USD 2.5 billion by 2033. This significant expansion highlights the value of understanding sourcing for products like Pntek plastic pipes. Buyers often consider the differences between UPVC vs CPVC pipes when making purchasing decisions. Knowing what UPVC fittings are used for helps define specific needs. This guide will also assist those wondering where to buy plastic pipe fittings online.

Key Takeaways

- Clearly define your UPVC valve needs. This includes valve type, size, and material. This helps manufacturers give you correct prices.

- Find good Chinese manufacturers. Use online platforms and check their certifications. This ensures you get quality products.

- Ask for many quotes and compare them carefully. Look at prices, delivery times, and payment terms. This helps you find the best deal.

- Negotiate for better prices. Ask for discounts on large orders. Also, try to get good payment plans.

- Check the quality of your order. Ask for product samples. You can also use outside inspectors. This makes sure your valves are good.

Define Your UPVC Valve Requirements

Defining specific requirements forms the foundation for successful procurement. Clear specifications help manufacturers provide accurate quotes and ensure the final product meets operational needs.

Specify Valve Type, Size, and Pressure Ratings

Buyers must clearly specify the exact type of UPVC valve required for their application. Manufacturers offer a variety of UPVC valves. These include:

- UPVC Butterfly Valves (centric, geared, or handle type)

- UPVC Ball Valves

- UPVC Foot Valves

- UPVC Gate Valves

- UPVC Globe Valves

- UPVC Check Valves

Each type serves a distinct purpose. Specifying the correct valve size and required pressure ratings (e.g., PN10, PN16) ensures compatibility with existing systems and safe operation.

Detail Material Grades and Seal Specifications

The material composition of UPVC valves directly impacts their performance and longevity. Manufacturers often use premium-grade materials. For example, a typical valve might feature:

| Component | Material |

|---|---|

| Body | Polypropylene |

| Handle Type | Long Handle Polypropylene |

| Ball | Polypropylene |

| Seat | EPDM |

| O-ring | Nitrile Rubber |

| Cap | Polypropylene |

This combination of polypropylene and UPVC provides excellent resistance to chemicals, corrosion, and wear. UPVC (Unplasticized Polyvinyl Chloride) offers high pressure tolerance, weather resistance, and durability for long-term water systems and chemical pipelines.

Seal specifications are equally critical for leak-proof operation. Common seal materials include EPDM, Nitrile Rubber (NBR), TPE, and TPV. These materials ensure a secure seal and maintain system integrity. For instance, TPE seat material is pressure-resistant and elastic, while NBR O-rings are high-pressure rated. Manufacturers test valves with significant water pressure, such as 16pn, to confirm leak-proof performance.

Determine Order Quantity and Project Timelines

Clearly stating the desired order quantity allows manufacturers to offer appropriate pricing tiers and production schedules. Larger volumes often qualify for better unit prices. Additionally, communicating project timelines helps manufacturers manage their production capacity and delivery logistics effectively. This ensures timely delivery of the UPVC valves for project completion.

Identify Reputable Chinese Manufacturers of Plastic Pipes and Valves

Identifying reputable Chinese manufacturers of plastic pipes and valves is a critical step in securing quality UPVC valves at competitive prices. This process involves thorough research and verification.

Leverage B2B Platforms and Industry-Specific Directories

B2B platforms and industry-specific directories offer excellent starting points for finding potential suppliers. Alibaba, for instance, stands as a leading B2B platform for sourcing PVC check valves from China. This platform provides access to numerous suppliers, including those specializing in plastic valves, and offers tools for price comparison and supplier evaluation. Buyers can review various metrics to assess supplier reliability.

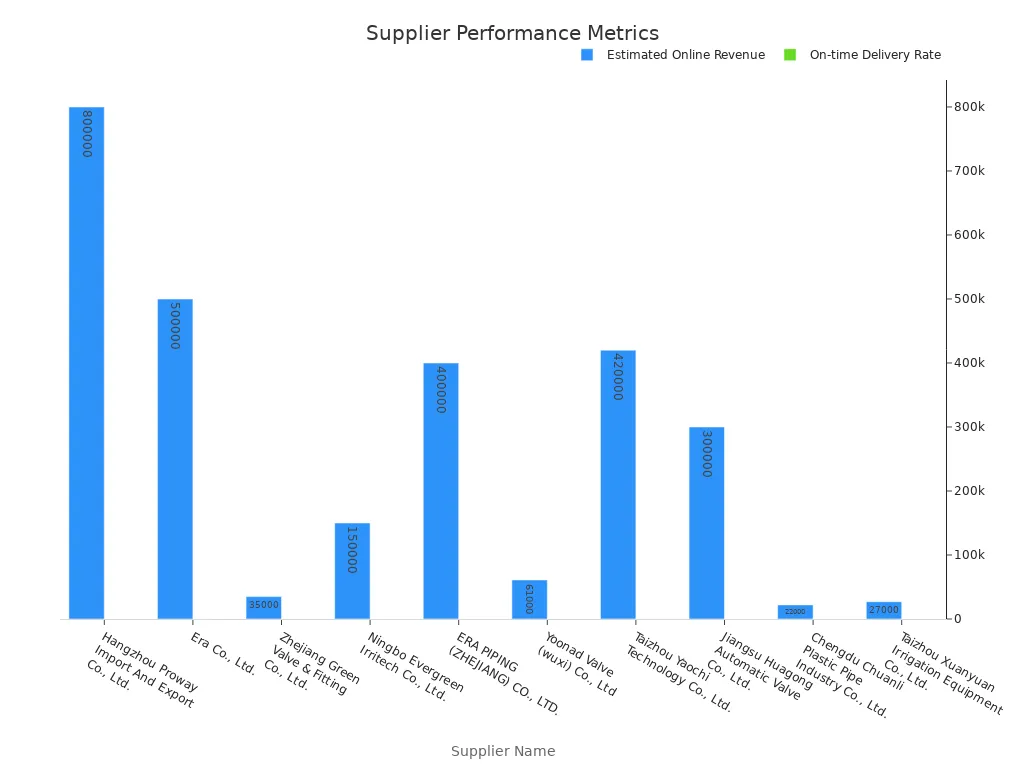

| Supplier Name | Location | Avg. Response Time | On-time Delivery Rate | Customer Rating | Estimated Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|

| Hangzhou Proway Import And Export Co., Ltd. | Zhejiang | ≤3h | 97.1% | 4.6 / 5.0 | US $800,000+ | 29% |

| Era Co., Ltd. | Zhejiang | ≤6h | 100.0% | 5.0 / 5.0 | US $500,000+ | <15% |

| Zhejiang Green Valve & Fitting Co., Ltd. | Zhejiang | ≤4h | 84.8% | 5.0 / 5.0 | US $35,000+ | 35% |

| Ningbo Evergreen Irritech Co., Ltd. | Zhejiang | ≤6h | 93.6% | 4.9 / 5.0 | US $150,000+ | 19% |

| ERA PIPING (ZHEJIANG) CO., LTD. | Zhejiang | ≤4h | 88.9% | 5.0 / 5.0 | US $400,000+ | 36% |

| Yoonad Valve (wuxi) Co., Ltd | Jiangsu | ≤3h | 76.9% | 5.0 / 5.0 | US $61,000+ | 30% |

| Taizhou Yaochi Technology Co., Ltd. | Zhejiang | ≤3h | 100.0% | 5.0 / 5.0 | 420,000+ | 15% |

| Jiangsu Huagong Automatic Valve Co., Ltd. | Jiangsu | ≤5h | 94.6% | 4.8 / 5.0 | US $300,000+ | 45% |

| Chengdu Chuanli Plastic Pipe Industry Co., Ltd. | Sichuan | ≤3h | 100.0% | 4.9 / 5.0 | US $22,000+ | 15% |

| Taizhou Xuanyuan Irrigation Equipment Co., Ltd. | Zhejiang | ≤2h | 95.7% | 4.9 / 5.0 | US $27,000+ | 25% |

This table illustrates various supplier performance metrics. Buyers can also visualize supplier performance through charts.

Zhejiang Xier Plastic Valve Lead Co., Ltd., a professional China UPVC Butterfly Valve supplier since 1993, is located in Zhejiang Province. They specialize in PVC and PPR Ball Valve manufacturing. They have achieved ISO9001, SGS, CNAS, and BS. EN 1213 Certificates.

Prioritize Manufacturers Specializing in UPVC Valve Production

Focusing on manufacturers with a strong specialization in UPVC valve production ensures expertise and quality. These companies often possess advanced manufacturing capabilities and a deep understanding of the product.

- Changzhou XITA Plastic Products Co., Ltd. specializes in comprehensive plastic pipeline system solutions. Their valve portfolio includes ball valves, butterfly valves, check valves, diaphragm valves, and motorized/pneumatic valve systems.

- Huasheng Pipeline Technology Co., Ltd. offers over 35 years of experience. They provide comprehensive manufacturing capabilities for UPVC, CPVC, PPH, and PE piping systems, including valves.

- Tommur Industry (Shanghai) Co., Ltd. stands as one of China’s largest manufacturers of plastic piping products. Their range includes complete piping system solutions with pipes, fittings, and valves.

- Zhejiang ERA Co., Ltd. is a dominant industry player. Their product line includes PVC threaded fittings and finds wide use in water supply and irrigation systems, indicating valve production as part of their comprehensive solutions.

- NBQXHY (Ningbo QXH Industrial Co., Ltd.) manufactures high-quality PVC pipes, fittings, and valves. They emphasize Schedule 40 and Schedule 80 specifications.

Verify Manufacturer Certifications and Export Experience

Verifying certifications and export experience provides assurance of product quality and reliable international trade practices. Reputable manufacturers hold various certifications.

- ISO 9001 ensures high-quality management systems in manufacturing.

- CE Marking signifies compliance with EU safety, health, and environmental protection standards for the European market.

- ASTM Standards (e.g., ASTM D1784, ASTM D2665) are global standards for material quality and performance, ensuring structural integrity.

- Other relevant certifications include OHSAS, PED, NSF, and UPC.

Manufacturers with extensive export experience demonstrate their capability to handle international logistics and compliance. Many Chinese manufacturers export their plastic pipes and valves globally. Their products reach Asia, the Middle East, Australia, Africa, Europe, America, and South America. These companies often operate under their own brands, such as ‘Huasheng’ and ‘CENIT’, and also offer OEM services. They ensure fast delivery through sufficient stock of full-size and different standard products, offering one-stop solutions. Typical payment terms require a 30% prepayment, with the balance due before shipping or upon receipt of the bill of lading. TT and LC are accepted. They commonly offer a 12-month warranty period after customers receive the products. Their products are often made from 100% Virgin PVC and produced according to international standards like F1970. They are suitable for drinking water, industrial use, and building applications, available in various colors like white, grey, black grey, and blue.

Master the Art of Requesting and Comparing Quotes

Effective procurement of UPVC valves depends heavily on a well-structured request for quotation (RFQ) and a thorough comparison of supplier offers. This process ensures buyers receive competitive pricing and suitable products.

Prepare a Comprehensive Request for Quotation (RFQ)

A detailed RFQ provides manufacturers with all necessary information to submit accurate bids. Buyers must clearly outline their needs. Essential information includes:

- Material Specifications: Specify UPVC, stainless steel, cast iron, bronze, or PVC.

- Valve Type: Indicate ball valve, gate valve, butterfly valve, or globe valve.

- Valve Size: Provide dimensions and connection types.

- Pressure and Temperature Ratings: State maximum and minimum values.

- End Connections: Specify flanged, threaded, or welded.

- Actuation Type: Detail manual, pneumatic, electric, or hydraulic.

- Industry Standards and Certifications: Ensure compliance with API, ANSI, ASME, ISO, or ASTM.

- Application: Describe the intended use, such as high-pressure steam, corrosive fluids, or gas pipelines.

- Operating Conditions: Include temperature, pressure, and flow rate.

- Special Requirements: Mention fire-safe design or anti-corrosive coatings.

For UPVC valves, buyers must specify chemical resistance to a wide range of chemicals, including acids, alkalis, and salts. The maximum service temperature of approximately 140°F (60°C) and its pressure handling capacity at different temperatures are also essential details. This is especially important when dealing with corrosive media or specific temperature requirements.

Additional RFQ components include:

- Quantity and Delivery Requirements: State the number of valves, expected delivery timeline, and phased delivery schedules for bulk procurement.

- Testing and Inspection Criteria: Request hydrostatic testing, leakage testing, material composition testing, third-party inspection, and factory acceptance tests (FAT). Also, specify required documentation like mill test certificates and compliance certificates.

- Commercial Terms and Conditions: Outline payment terms (LC, advance payments, credit period), Incoterms (FOB, CIF, DDP), warranty and guarantees, and penalty clauses for late delivery or quality issues.

- Submission Requirements: Clarify the submission format (digital/physical), deadlines, and supporting documents (company profile, past project experience, references).

Obtain Multiple Quotes for UPVC Valves

Buyers should solicit quotes from several qualified manufacturers. This strategy allows for a broader comparison of pricing, product specifications, and service offerings. Multiple quotes help buyers identify the most competitive and reliable suppliers.

Analyze Quotes Beyond Price: Terms, Lead Time, and MOQ

A thorough analysis of quotes goes beyond the unit price. Buyers must evaluate the entire package.

- Payment Terms: Common payment terms from Chinese manufacturers include L/C, D/A, D/P, T/T, and Trade Assurance. Pntek, for example, emphasizes offering "easy payment terms" as part of their customer-centric approach. This focus on flexibility benefits buyers.

- Lead Time: Consider the delivery schedule.

Typical lead times for UPVC valve orders from Chinese suppliers range from 5 to 30 days after receiving the down-payment, with the exact duration depending on the order quantity.

Buyers should align lead times with project schedules. - Minimum Order Quantity (MOQ): Manufacturers often have MOQs. While some suppliers, like Pntek, advertise "Low MOQ" for UPVC valves, they may not specify a numerical standard. Buyers should clarify the exact MOQ for their specific order.

Implement Effective Negotiation Strategies for Better Pricing

Effective negotiation plays a crucial role in securing the best prices for UPVC valves. Buyers can employ several strategies to achieve more favorable terms and reduce overall procurement costs.

Utilize Volume-Based Discounts for Larger Orders

Manufacturers often offer significant price reductions for larger order quantities. This practice incentivizes buyers to purchase more, leading to lower per-unit costs. Understanding the typical discount structures helps buyers plan their procurement effectively.

| Company Name | Min MOQ | Price Range (USD) | Discount Structure |

|---|---|---|---|

| Tangshan Qiming Trade Co., Ltd. | 1 pc | $5.50-6.50 | Volume Discounts |

| Sichuan Jiyang Electromechanical Equip | 2 pcs | $6-6.50 | Volume Discounts |

| Jiangsu Shoulong Valve Co., Ltd. | 1 set | $38-132 | Huge Bulk Discount |

| Zhejiang Green Valve & Fitting Co. | 100 pcs | $4.50-10 | Significant Bulk Discount (1000+ pcs) |

| Taizhou Jinsheng Plastic Co., Ltd. | 2000 pcs | $0.53 | Extremely Low Price Point for High Volume |

| Yiwu Yifan E-Commerce Firm | 220 pcs | $0.10-0.19 | Deep Bulk Discounts (22000+ pcs) |

| Tommur Industry (shanghai) Co., Ltd. | 1000 pcs | $0.25-0.30 | Very Low Price at Volume |

Manufacturers like Sichuan Jiyang and Tangshan Qiming explicitly offer volume discounts. Higher Minimum Order Quantities (MOQs) often lead to significant or deep bulk discounts, resulting in lower per-unit prices. For example, Zhejiang Green Valve & Fitting Co. provides substantial discounts for orders exceeding 1000 pieces. Yiwu Yifan E-Commerce Firm offers deep bulk discounts for quantities over 22,000 pieces. Extremely low price points become achievable with very high MOQs, as seen with Taizhou Jinsheng Plastic Co., Ltd. for 2000 pieces and Tommur Industry (Shanghai) Co., Ltd. for 1000 pieces. Specialized products, such as pneumatic actuation valves from Jiangsu Shoulong Valve Co., Ltd., also qualify for huge bulk discounts.

Negotiate Favorable Payment Structures

Payment terms significantly impact a buyer’s cash flow and financial flexibility. Negotiating favorable payment structures can provide substantial benefits. Buyers can propose various payment arrangements, such as a lower upfront deposit, extended payment periods, or payment upon delivery. Some manufacturers may accept Letters of Credit (L/C), Documents Against Acceptance (D/A), Documents Against Payment (D/P), or Telegraphic Transfers (T/T). Trade Assurance, offered by platforms like Alibaba, also provides a secure payment option. A manufacturer willing to offer flexible payment terms demonstrates a commitment to building a strong business relationship.

Explore Off-Season Deals and Long-Term Partnership Benefits

Strategic buyers can leverage off-season periods to secure better deals. Demand for UPVC valves might decrease during certain times of the year, allowing manufacturers to offer lower prices to maintain production levels. Inquire about potential discounts during these slower periods.

Building long-term partnerships with Chinese UPVC valve suppliers offers numerous advantages beyond immediate cost savings. These relationships foster consistent supply and ensure a steady flow of products. Partners often provide valuable technical support, helping buyers optimize system performance. Quality assurance becomes more reliable, as products consistently meet international standards for safety and performance.

Long-term collaborations also lead to competitive pricing, providing access to cost-efficient solutions over time. Suppliers bring dependable products and specialized knowledge, enhancing reliability and expertise. Clients benefit from responsive customer service and timely deliveries, fostering a strong collaborative relationship.

Furthermore, top manufacturers employ stringent quality control and advanced production methods, leading to valves that perform consistently and prevent failures in demanding environments. Leading suppliers invest significantly in research and development, offering the latest valve technologies, smart solutions, and expert engineering consultation to optimize system performance. While initial costs might be higher for premium products, their longevity, reduced maintenance needs, and efficient operation significantly lower long-term operational expenses, reducing the total cost of ownership. Established manufacturers typically have robust global supply chains and efficient production management, ensuring timely product delivery and minimizing project delays. A global service network and dedicated after-sales teams provide prompt technical support, spare parts, and repair services, ensuring continuous equipment operation. Utilizing industry-leading valve solutions ultimately improves the quality and reliability of a buyer’s own products, thereby boosting their market competitiveness.

Be Prepared to Disengage if Terms Are Unfavorable

Buyers must maintain a firm stance during negotiations. If a manufacturer’s terms remain unfavorable despite negotiation efforts, buyers should be prepared to disengage. This willingness to walk away signals seriousness and can sometimes prompt a supplier to reconsider their offer. It also prevents buyers from committing to deals that do not meet their financial or operational requirements.

Be Prepared to Disengage if Terms Are Unfavorable

Buyers must maintain a firm stance during negotiations. If a manufacturer’s terms remain unfavorable despite negotiation efforts, buyers should be prepared to disengage. This willingness to walk away signals seriousness. It can sometimes prompt a supplier to reconsider their offer. It also prevents buyers from committing to deals that do not meet their financial or operational requirements.

Disengagement is a powerful negotiation tactic. It demonstrates a buyer’s commitment to their procurement objectives. Suppliers often recognize a buyer’s resolve when they are ready to explore other options. This can lead to improved offers from the initial supplier.

Consider these points when preparing to disengage:

- Clear Boundaries: Buyers establish clear boundaries for acceptable terms. These include price, quality standards, delivery schedules, and payment conditions.

- Alternative Suppliers: Having multiple quotes from various manufacturers strengthens a buyer’s position. It provides viable alternatives if one negotiation fails.

- Cost-Benefit Analysis: Buyers conduct a thorough cost-benefit analysis. They compare the potential risks and costs of an unfavorable deal against the effort of finding a new supplier.

- Long-Term Impact: Accepting poor terms can lead to long-term issues. These include higher costs, compromised quality, and project delays. Disengaging protects the project’s integrity.

A buyer’s ability to disengage ensures they secure the best possible terms. It prevents them from being pressured into agreements that do not serve their interests. This strategic approach ultimately leads to more successful and cost-effective procurement outcomes. It reinforces the buyer’s leverage in the market.

💡 Tip: Always have a backup plan. Researching multiple suppliers from the start provides leverage. It makes disengaging from an unfavorable deal less risky.

Ensure Robust Quality Control for UPVC Valve Shipments

Implementing robust quality control measures is essential for securing high-quality UPVC valves. These measures safeguard against defects and ensure product reliability. Buyers must proactively engage in quality assurance throughout the procurement process.

Request and Evaluate Product Samples

Requesting and thoroughly evaluating product samples provides direct insight into a manufacturer’s quality. Buyers should critically assess these samples before placing large orders. When reviewing UPVC valve product samples, critical aspects to evaluate include:

- Pressure Testing Standards: This involves both hydrostatic pressure tests and air pressure tests. Hydrostatic tests fill the valve with liquid and pressurize it to 1.5 times the maximum working pressure. This checks for leaks or deformation. Air pressure tests use compressed air to detect smaller leaks with a soap solution or leak detector.

- Flow-Rate Testing: This determines the valve’s ability to pass fluid. It involves calculating the Flow Coefficient (Cv), which measures the volume of water (US gallons per minute) that flows through the valve with a 1 psi pressure drop.

- Diaphragm Integrity Testing: The diaphragm is crucial for fluid separation and flow control. Evaluation includes visual inspection for cracks or wear. Functional testing repeatedly opens and closes the valve to check for fatigue or failure.

- Actuator Performance Testing: For valves with actuators, this assesses response time. It checks how quickly the valve opens or closes after a signal. Torque testing ensures the actuator generates sufficient force for smooth operation.

- Temperature and Chemical Resistance Testing: UPVC valves must perform in various environments. Temperature testing checks for brittleness at low temperatures and material degradation at high temperatures. Chemical resistance testing exposes the valve to acids, alkalis, and solvents. This checks for corrosion, swelling, or degradation.

Discuss Manufacturer’s Quality Assurance Protocols

Buyers should engage manufacturers in detailed discussions about their internal quality assurance protocols. This includes understanding their manufacturing processes, material sourcing, and in-house testing procedures. A reputable manufacturer readily shares their quality control documentation and explains how they maintain consistent product standards. This transparency builds trust and confidence in their products.

Consider Independent Third-Party Inspections

Independent third-party inspection services offer an additional layer of quality verification. These services provide unbiased assessments of product characteristics. Through certifications, they ensure that UPVC valve shipments meet specified quality standards. This independent oversight helps mitigate risks and confirms compliance with international regulations. It gives buyers greater assurance regarding the quality and performance of their purchased valves.

Optimize Shipping and Logistics for Cost Savings

Efficient shipping and logistics significantly reduce the total cost of UPVC valve procurement. Buyers must understand various shipping terms and strategies. These elements directly impact final expenses and delivery timelines.

Understand Incoterms and Their Financial Implications

Incoterms, or International Commercial Terms, define responsibilities between buyers and sellers for the delivery of goods. They specify who pays for and manages the shipment, insurance, and customs duties. Choosing the right Incoterm impacts the final price of UPVC valves. For example, FOB (Free On Board) means the seller pays for transport to the port and loading onto the vessel. The buyer then assumes costs and risks from that point. CIF (Cost, Insurance, and Freight) means the seller covers costs and insurance to the destination port. Buyers should carefully select Incoterms that align with their logistical capabilities and cost preferences.

Compare Quotes from Multiple Freight Forwarders

Buyers should obtain quotes from several freight forwarders. Freight forwarders specialize in organizing shipments. They can offer competitive rates for air, sea, or land transport. Comparing their services and pricing helps buyers find the most cost-effective solution. Factors to consider include transit time, reliability, and insurance options. A good freight forwarder streamlines the shipping process. They also handle customs clearance efficiently.

Consolidate Shipments to Reduce Unit Costs

Consolidating multiple smaller orders into one larger shipment often leads to significant cost savings. Shipping a full container load (FCL) is generally more economical per unit than shipping less than a container load (LCL). Buyers can coordinate with their Chinese manufacturers to combine various UPVC valve types or other plastic pipe products into a single consignment. This strategy reduces overall freight charges. It also minimizes handling fees and customs processing costs. Strategic planning of order quantities supports shipment consolidation.

Build Sustainable Relationships with Suppliers of Plastic Pipes

Building strong, lasting relationships with Chinese manufacturers of plastic pipes is crucial for long-term procurement success. These partnerships extend beyond single transactions. They foster mutual trust and benefit both parties.

Maintain Clear and Consistent Communication

Effective communication forms the bedrock of any successful business relationship. Buyers must evaluate a supplier’s communication skills and responsiveness early on. A trustworthy supplier promptly addresses inquiries. They also provide clear and detailed information. To ensure clarity and avoid misunderstandings, consider these best practices:

- Build a Relationship First: Invest time in virtual introductions. Personal connections can lead to better accommodation for urgent requests and pricing discussions.

- Use Clear and Simple Language: Avoid jargon or slang. Only about 10% of China’s population speaks English. Simplify emails and calls. Focus on key points. Use visual elements like screenshots or product diagrams.

- Mind Cultural Nuances: Understand that ‘Face’ (mianzi) is crucial. Avoid direct confrontation. Use polite phrasing. Be aware of hierarchical structures. Focus discussions on the designated point of contact.

- Leverage Visual Aids: Photographs, product sketches, and flowcharts significantly reduce confusion. Use labeled diagrams for new designs. Consider video calls for complex components.

- Confirm in Writing: Always follow up phone calls or voice notes with an email. Summarize the conversation. This creates a written record and ensures accountability.

- Use the Right Communication Channels: WeChat is common for quick chats. Handle formal matters like major negotiations or documents via email or secure file-sharing platforms.

- Show Patience in Negotiations: Chinese partners often prefer a step-by-step approach. Being flexible and patient can lead to better rates or favorable payment terms for plastic pipes.

- Pay Attention to Time Zones and Holidays: Plan calls for decent overlap during the Chinese workday. Be aware of major holidays like Lunar New Year. Production lines may shut down for weeks during these times.

Leverage Repeat Business for Improved Pricing and Service

Consistent orders and repeat business offer significant advantages. Suppliers value loyal customers. They often reward this loyalty with improved pricing structures. Buyers can expect better unit costs over time. This applies to UPVC valves and other plastic pipes. Long-term partnerships also lead to enhanced service. Suppliers prioritize repeat clients. They offer faster response times and more flexible terms. This builds a reliable supply chain. It ensures a steady flow of high-quality products.

A systematic approach is key for successful UPVC valve procurement. Buyers define needs, research suppliers, negotiate terms, and ensure quality. This process helps achieve optimal pricing and a reliable supply of UPVC valves from China. Fostering long-term partnerships with manufacturers ensures sustained procurement success. These relationships provide consistent quality and better service over time.

FAQ

What are the main advantages of purchasing UPVC valves from Chinese manufacturers?

Chinese manufacturers offer competitive pricing due to efficient production scales. They provide a wide range of UPVC valve types and specifications. Many suppliers also possess extensive export experience and adhere to international quality standards.

How can buyers verify the quality of UPVC valves from China?

Buyers should request product samples for evaluation. They discuss the manufacturer’s quality assurance protocols. Consider independent third-party inspections for unbiased assessments. Verify certifications like ISO 9001 and ASTM standards.

What payment methods do Chinese UPVC valve suppliers typically accept?

Suppliers commonly accept Letters of Credit (L/C), Documents Against Acceptance (D/A), Documents Against Payment (D/P), and Telegraphic Transfers (T/T). Trade Assurance platforms also offer secure payment options.

What is the typical lead time for UPVC valve orders from China?

Lead times for UPVC valve orders generally range from 5 to 30 days. This duration depends on the order quantity and specific product requirements. Buyers should confirm exact timelines with their chosen supplier.