Selecting the appropriate Industrial Pipe Fittings for high-pressure systems is critical for both safety and operational integrity. Incorrect choices create immediate risks, including catastrophic failures, hazardous leaks, and significant downtime. Such incidents compromise personnel safety and lead to substantial financial losses. Pntek Plumbing Solutions offers a range of components, including robust PVC Ball Valves and corrosion-resistant thermoplastic fittings, which adhere to Pntek fittings performance standards. This commitment highlights why Pntek is a reliable supplier for global plumbing projects.

Key Takeaways

- Understand your system’s needs. Check pressure, temperature, and fluid type. This helps you pick the right fittings.

- Choose the correct material. Stainless steel, carbon steel, or special alloys each work best for different conditions. This ensures safety and long-lasting use.

- Pick the right fitting type. Welded fittings are permanent. Flanged fittings allow easy access. Threaded and compression fittings offer specific sealing benefits.

- Install fittings correctly. Match pressure ratings and size fittings properly. Follow installation guides to prevent leaks and ensure the system works well.

- Inspect and maintain fittings regularly. Look for signs of wear or damage. This helps avoid costly failures and keeps your system safe.

Understanding High-Pressure System Requirements for Industrial Pipe Fittings

Selecting the correct Industrial Pipe Fittings begins with a thorough understanding of the system’s specific demands. Engineers must evaluate several critical factors to ensure safety and operational efficiency. These factors include pressure, temperature, and the characteristics of the fluid being transported.

Defining System Operating Pressure and Design Pressure

System operating pressure refers to the normal pressure at which a system functions. Design pressure, however, represents the maximum pressure a system can safely withstand. This includes potential surges or abnormal conditions. High-pressure systems typically operate above 1000 psi (70 bar). They can extend to several thousand or even tens of thousands of psi. For example, high-pressure systems in the oil refinery industry often require pressure ranges up to 58,000 psi. These extreme pressures are crucial for optimizing refining processes. Ultra-high-pressure systems operate at even higher pressures, sometimes exceeding hundreds of thousands of psi.

Temperature Ranges and Their Impact on Fitting Performance

Temperature significantly influences the performance and integrity of pipe fittings. High temperatures can reduce the strength and durability of materials. As temperature increases, the atomic activity within steel pipes rises. This leads to a significant decrease in yield strength. For instance, 316 Stainless Steel maintains 100% of its allowable working pressure at 200°F. However, at 400°F, this drops to 96%, and at 1000°F, it further decreases to 76%. Engineers must consider the material’s high-temperature yield strength for applications in hot environments, such as boiler tubes.

Fluid Characteristics and Chemical Compatibility

The type of fluid flowing through the system dictates material selection for Industrial Pipe Fittings. Fluids can be corrosive, abrasive, or have specific chemical properties that react with certain materials. For example, strong acids or bases require materials like specialized alloys or certain plastics that resist chemical degradation. Abrasive slurries demand fittings with high wear resistance. Proper material selection prevents corrosion, erosion, and contamination, ensuring the longevity and safety of the entire system.

Essential Material Selection for High-Pressure Pipe Fittings

Choosing the correct material for high-pressure pipe fittings is paramount. The material directly impacts the fitting’s ability to withstand pressure, temperature, and corrosive elements. Engineers must carefully evaluate material properties to ensure system integrity and longevity.

Stainless Steel Grades (304, 316) for Corrosion Resistance

Stainless steel is a popular choice for many high-pressure applications due to its excellent corrosion resistance and strength. Two common grades, 304 and 316, offer distinct advantages.

304 stainless steel fittings provide good corrosion resistance. They are suitable for general residential and commercial potable water plumbing. This grade works well in indoor or dry environments. It also finds use in kitchen and food-processing equipment, as well as general construction. However, 304 stainless steel is not ideal for highly corrosive environments. It struggles with strong acids like sulfuric, hydrochloric, formic, and tartaric acids. It also shows vulnerability to chlorides, especially in warm or humid conditions. This can lead to pitting corrosion.

316 stainless steel offers superior corrosion resistance compared to 304. The primary distinction lies in the presence of molybdenum in 316. This element significantly enhances its resistance to corrosion and oxidation. While 304 stainless steel has a higher chromium content (minimum 18%) than 316 (16%), the 2% molybdenum in 316 is crucial. It provides greater resistance to chemical attacks and chlorides, such as seawater and de-icing salts. This makes 316 stainless steel ideal for applications with powerful corrosives, chlorides, and salt exposure. These include marine/seawater, industrial-commercial chemical, and pharmaceutical equipment.

For environments involving corrosive liquids or vapors, 316 stainless steel is the preferred choice. It fights corrosion from salt, moisture, and chemicals more effectively. This makes it suitable for:

- Marine environments

- Coastal installations

- Chemical processing systems

- Swimming pools

316 stainless steel is specifically recommended for applications involving saltwater or marine exposure, harsh chemicals or high moisture, medical components, and high temperatures with corrosive substances. Although 316 is considered marine grade, it is not entirely resistant to warmer seawater. Warmer seawater can still cause chloride pitting, but 304 is even less resistant in such conditions.

Carbon Steel for Strength and Cost-Effectiveness

Carbon steel is a widely used material for high-pressure pipe fittings. It offers an excellent balance of strength and cost-effectiveness. Manufacturers produce carbon steel by alloying iron with carbon. This composition provides high tensile strength and durability. These properties make it suitable for many industrial applications.

Carbon steel fittings perform well in systems where corrosion is not a primary concern. They handle high pressures effectively. Industries often choose carbon steel for its robust mechanical properties and lower material cost compared to stainless or alloy steels. However, carbon steel lacks inherent corrosion resistance. It requires protective coatings or linings in corrosive environments. Without protection, it can rust and degrade, compromising system integrity.

Alloy Steels and Special Alloys (e.g., Inconel 625) for Extreme Conditions

For the most demanding high-pressure applications, engineers turn to alloy steels and special alloys. These materials offer enhanced properties beyond standard carbon or stainless steels. They provide superior strength, temperature resistance, and corrosion resistance in extreme environments.

Alloy steels contain additional elements like chromium, nickel, molybdenum, and vanadium. These elements improve specific material characteristics. They enhance toughness, hardness, and resistance to high temperatures and corrosive media.

Inconel 625 is a prime example of a special alloy. It is a nickel-chromium-molybdenum alloy. This alloy is renowned for its exceptional strength and resistance to a wide range of corrosive environments. It also performs well at elevated temperatures. Inconel 625 pipe fittings maintain strength and structural integrity in extreme heat. They can withstand temperatures up to 982°C (1800°F). This makes them suitable for demanding applications in aerospace and power generation.

However, Inconel 625 also has specific temperature limitations. Inconel alloy 625 flanges, when in the annealed condition, should not be used over 645°C. Exposure in the range of 538°C to 760°C leads to a severe loss of impact strength at room temperatures.

The pressure ratings for Inconel 625 fittings also vary by class and temperature. For example, at temperatures from -29°C to 38°C, a Class 150 fitting can handle 20.0 MPa. A Class 2500 fitting can handle 430.9 MPa. For all classes, the maximum pressure decreases as the temperature approaches 645°C.

| Class | Temperature Range (°C) | Maximum Pressure (MPa) |

|---|---|---|

| 150 | -29 to 38 | 20.0 |

| 300 | -29 to 38 | 51.7 |

| 600 | -29 to 38 | 103.4 |

| 900 | -29 to 38 | 155.1 |

| 1500 | -29 to 38 | 258.6 |

| 2500 | -29 to 38 | 430.9 |

| All Classes | Not exceeding 645 | (Pressure decreases with temperature) |

These advanced materials are critical for applications requiring extreme performance. They ensure safety and reliability in the harshest industrial conditions.

Types of High-Pressure Industrial Pipe Fittings and Their Applications

Understanding the different types of Industrial Pipe Fittings is crucial for designing and maintaining high-pressure systems. Each fitting type offers unique advantages and disadvantages. Engineers select specific fittings based on the system’s pressure, temperature, fluid characteristics, and maintenance requirements.

Welded Fittings for Permanent, High-Integrity Connections

Welded fittings create permanent, high-integrity connections. These fittings are ideal for systems requiring maximum leak prevention and structural strength. They are common in critical applications like oil and gas pipelines, chemical processing plants, and power generation facilities. Welding forms a continuous, homogeneous joint. This eliminates potential leak paths often associated with mechanical connections.

Quality control is paramount for welded fittings in high-pressure environments. A modern quality management system (QMS) ensures the reliability of these components. This system includes several critical steps:

- Material Verification: Spectral analysis confirms metal composition. Testing checks for tensile strength, hardness, and corrosion resistance. Pre-weld heat treatment verification also occurs.

- Dimensional and Visual Inspection: Technicians perform tolerance checks. They visually inspect for defects like cracks or burrs. Fitment validation ensures proper assembly.

- Non-Destructive Testing (NDT): Ultrasonic testing, magnetic particle, and radiography detect hidden defects. This is especially crucial for welding integrity in high-pressure systems.

- Pressure and Vacuum Testing: Hydrostatic and pneumatic tests validate operation under rated pressure and stress. ASME and ISO protocols require these tests.

- Traceability and Documentation: Full batch traceability uses serial numbers. Data management systems store statistical process control records.

Internationally recognized standards guide quality in fittings supply. These include:

- ISO 9001 – This provides a general quality management framework.

- API 6A / 6D – These are valve and fitting performance standards for energy applications.

- ASME B16.5 / B16.34 – These specify mechanical design and pressure tolerance.

- NACE MR0175 / ISO 15156 – These qualify fittings for sour gas and corrosion-intensive conditions.

Tungsten Inert Gas (TIG) welding is a precise procedure. It uses a non-consumable tungsten electrode. This method produces high-quality welds. It is ideal for thin materials and critical applications. TIG welding is often used for stainless steel and non-ferrous metals. However, it requires skilled operators due to its complexity.

Post-welding verification for butt weld pipe fittings is also essential. This process involves:

- Weld Profile and Geometry Analysis: Technicians evaluate weld reinforcement height, root penetration, and face/root concavity. They use profile gauges and digital measurement systems. This ensures optimal stress distribution and mechanical performance.

- Heat-Affected Zone Inspection: Hardness testing and metallographic examination occur across the weld zone. This identifies microstructural changes, potential hard spots, or soft zones. These could affect mechanical properties and corrosion resistance.

- Pressure Testing Requirements: Hydrostatic testing validates the pressure-containing capability. This occurs under controlled conditions. Test pressure levels typically exceed design pressure by specified safety factors. Digital pressure monitoring systems provide precise control and documentation.

Key inspection methods for quality control in pipe welding include:

- Visual Inspection: This examines welds for surface defects. Examples include cracks, porosity, or misalignment.

- Radiographic Inspection: X-rays or gamma rays detect hidden flaws. These include voids or inclusions within the weld.

- Ultrasonic Inspection: This detects internal defects. It measures sound wave reflections within the weld.

- Magnetic Particle Testing: This identifies surface and slightly subsurface defects in ferromagnetic materials.

- Dye Penetrant Inspection: This highlights surface defects. It applies a liquid dye that penetrates cracks or voids.

Flanged Fittings for Accessibility and Maintenance

Flanged fittings provide a robust and accessible connection method. They consist of two flanges, a gasket, and bolts. Workers bolt the flanges together, compressing the gasket between them. This creates a seal. Flanged connections allow for easier assembly and disassembly. This makes them suitable for systems requiring regular maintenance, inspection, or component replacement. They are common in large-diameter piping and systems where components need periodic removal. While offering excellent sealing capabilities, proper bolt tensioning and gasket selection are critical. Incorrect installation can lead to leaks, especially in high-pressure applications.

Threaded Fittings (NPT, ORB) for Specific Pressure Ranges

Threaded fittings offer a convenient and relatively simple connection method. They rely on mating threads to create a seal. Two common types are National Pipe Taper (NPT) and O-Ring Boss (ORB) fittings. Each type has specific pressure limitations and sealing mechanisms.

| Comparison Aspect | NPT | ORB |

|---|---|---|

| Pressure Suitability | Low-pressure systems, general plumbing, gas lines | High-pressure hydraulic systems |

| Sealing Mechanism | Tapered threads, seals by compression (leakage risk if mis-installed) | Straight threads with O-ring for superior sealing |

NPT fittings use tapered threads. These threads narrow towards the end. The sealing mechanism relies on the mechanical compression of these tapered threads. Threads compress against each other to create a seal through friction and pressure. Installers often enhance this seal with thread sealant or Teflon tape. NPT fittings are common in plumbing, gas piping, and low- to medium-pressure fluid systems. However, they are generally not as effective in high-pressure environments as ORB fittings. They are more susceptible to leaks under high-pressure conditions. This is due to their reliance on thread compression. The threads can wear down or become damaged over time. This reduces seal effectiveness. The metal-to-metal seal is prone to wear. This is especially true with frequent disassembly or extreme pressure.

ORB fittings feature straight threads. These threads provide mechanical support. The sealing mechanism uses an O-ring. This O-ring sits in a groove. It compresses against the mating surface. This creates a tight, leak-proof seal. The O-ring is made from elastomeric materials. Examples include nitrile, Viton, or other rubber compounds. When tightened, the O-ring compresses. This forms a reliable seal. ORB fittings excel in high-pressure applications. The flexible and reliable O-ring seal adapts to pressure fluctuations. It maintains integrity. This makes them well-suited for hydraulic systems operating under high pressure. They are ideal for aerospace, high-pressure fluid systems, and applications where a strong, reliable seal is critical. ORB fittings ensure a consistent, reliable seal under varying pressures.

Compression Fittings for Precision and Leak-Tight Seals

Compression fittings offer a highly effective solution for creating precision and leak-tight seals in high-pressure systems. These fittings do not require welding, soldering, or threading. Instead, they rely on mechanical force to create a secure connection. This makes them a versatile choice for various applications where reliability and ease of installation are crucial.

A typical compression fitting consists of three main components: the fitting body, a compression nut, and a ferrule (or olive). Installers slide the nut and ferrule over the pipe or tubing. They then insert the pipe into the fitting body. As the installer tightens the nut, it compresses the ferrule onto the pipe. This action creates a tight seal between the pipe, the ferrule, and the fitting body. This mechanical compression ensures a robust, leak-proof connection capable of withstanding significant pressure.

Compression fittings provide several advantages. They offer quick installation, reducing downtime during assembly or repair. Their design allows for easy disassembly and reassembly, which simplifies maintenance and component replacement. This reusability makes them cost-effective over the long term. The precision engineering of these fittings ensures a consistent and reliable seal, even under fluctuating pressures and temperatures.

Many industries prefer compression fittings for their superior performance in demanding environments. They are critical for maintaining fluid integrity and ensuring safety.

- Oil & Gas: Instrumentation compression fittings are used for upstream and downstream applications. These include oilfield logging, exploration, and on offshore oil rigs, especially in harsh conditions. Bulkhead instrumentation fittings connect tubing lines to gauges and valves in instrument panels.

- Medical & Pharmaceutical: These fittings are critical for medical device equipment and pharmaceutical production. They find use in life monitoring devices, surgical equipment, and chemical compound processing.

- Power Generation: Compression fittings enable leak-free connections in process, power, nuclear, and other critical power generating applications. They often require exotic metals for high corrosion resistance.

- Aerospace: These fittings are used in virtually all aerospace applications and equipment, including life support systems in aircraft and shipbuilding. Suppliers need specific certifications for these components.

Other common applications for these specialized Industrial Pipe Fittings include:

- Industrial hydraulics: Machinery and equipment requiring hydraulic power use these fittings. They must endure intense pressure from hydraulic fluids.

- Gas transmission lines: These fittings are employed for natural gas and other high-pressure gases. They ensure safety and integrity in distribution.

- High-pressure washers: Equipment that cleans surfaces with pressurized water or cleaning solutions uses these essential fittings.

- Research laboratories: Experimental setups for precise control of high-pressure gases or liquids utilize these fittings.

- Aerospace and defense: Aircraft and military vehicles apply these fittings for fuel, oil, and hydraulic systems. Failure is unacceptable in these critical applications.

The table below summarizes key applications and advantages of compression fittings:

| Application | Usage | Advantages |

|---|---|---|

| Plumbing (Water & Gas Lines) | Connecting pipes in water and gas lines. | Leak-proof, quick installation, corrosion-resistant. |

| Hydraulic Systems | High-pressure fluid transmission. | High-pressure tolerance, secure, leak-free connections. |

| Automotive (Brake & Fuel Lines) | Safe fluid transmission in fuel and brake lines. | Critical for safety, leak-proof, high pressure resistance. |

| Instrumentation & Control | Industrial instruments, chemical processing, laboratory systems. | Precise fluid/gas control, secure connections. |

| HVAC Systems | Refrigerant lines and air ducts. | Leak-proof, durable, suitable for both low and high pressure. |

| Offshore & Marine | Critical fluid handling in marine vessels and offshore rigs. | Corrosion-resistant, reliable for harsh environments. |

| Food & Beverage Industry | Fluid handling in food production and beverage lines. | Hygienic, corrosion-resistant, ensures safety. |

Compression fittings provide a reliable and efficient solution for creating secure, leak-tight connections in a wide array of high-pressure systems. Their ease of installation and robust performance make them an indispensable component in modern industrial infrastructure.

Sizing, Pressure Ratings, and Installation Best Practices

Properly sizing pipe fittings, understanding their pressure ratings, and implementing correct installation techniques are crucial for high-pressure systems. These steps ensure operational safety and system longevity.

Matching Fitting Pressure Ratings with System Requirements

Engineers must match fitting pressure ratings precisely with system requirements. In the chemical processing industry, where corrosive and often hazardous fluids are handled under pressure, selecting pipes with appropriate pressure ratings and materials resistant to chemical corrosion is critical for maintaining operational safety. Industry standards such as ASME, ASTM, and API determine the pressure ratings for pipe fittings. Common pressure ratings include Class 150, 300, 600, 900, 1500, and 2500, as per ASME B16.5 standards for flanges and fittings. Schedule 40, 80, 160, and XXS represent thickness classifications for steel pipes and fittings. API 6A also provides pressure ratings for oil and gas applications.

| Pressure Class | Maximum Working Pressure (psi) | Typical Applications (including chemical processing) |

|---|---|---|

| Class 125 | 125 | Low-pressure piping systems, plumbing, irrigation, residential, commercial, and light industrial applications |

| Class 150 | 150 | Low-pressure systems, water supply, low-pressure steam, air, non-corrosive fluids |

| Class 300 | 300 | Higher-pressure systems, steam, gas, liquids, wide range of industrial processes |

| Class 600 | 600 | Systems requiring up to 600 psi, suitable for various industrial applications |

| Class 900 | 900 | High-pressure piping systems, petrochemical, chemical processing, power generation |

| Class 1500 | 1500 | Critical applications in oil and gas, chemical processing, very high-pressure fluid handling |

| Class 2500 | 2500 | Extremely high-pressure applications in oil and gas, petrochemical, and other sectors |

Engineers must consider fluid type, temperature, and overall pressure conditions to select the appropriate pressure class. This ensures system safety and integrity, especially in chemical processing.

Correct Sizing for Flow Dynamics and Pressure Integrity

Correct sizing of pipe fittings is essential for optimal flow dynamics and pressure integrity. Undersizing fluid lines results in high pressure loss and system overheating. Oversizing lines increases system cost. Undersized hose or tube can cause turbulent flow and excessive heat buildup. Over-sized hose or tube can add cost, size, and weight to a system. It can also decrease the rate of flow. When fluid flows, mechanical energy is lost to overcome viscous forces within the fluid. This appears as a pressure drop. This lost energy dissipates as heat energy in the oil, potentially leading to cooling problems and shortening oil life. Frictional losses in pipework depend mainly upon pipe length, cross-sectional area, surface roughness, number of bends, flow velocity, and fluid viscosity.

Recommended fluid velocities for hydraulic systems include:

- Suction: 2-4 feet/sec.

- Return: 10-15 feet/sec.

- Medium Pressure: 15-20 feet/sec.

- High Pressure: 20-25 feet/sec.

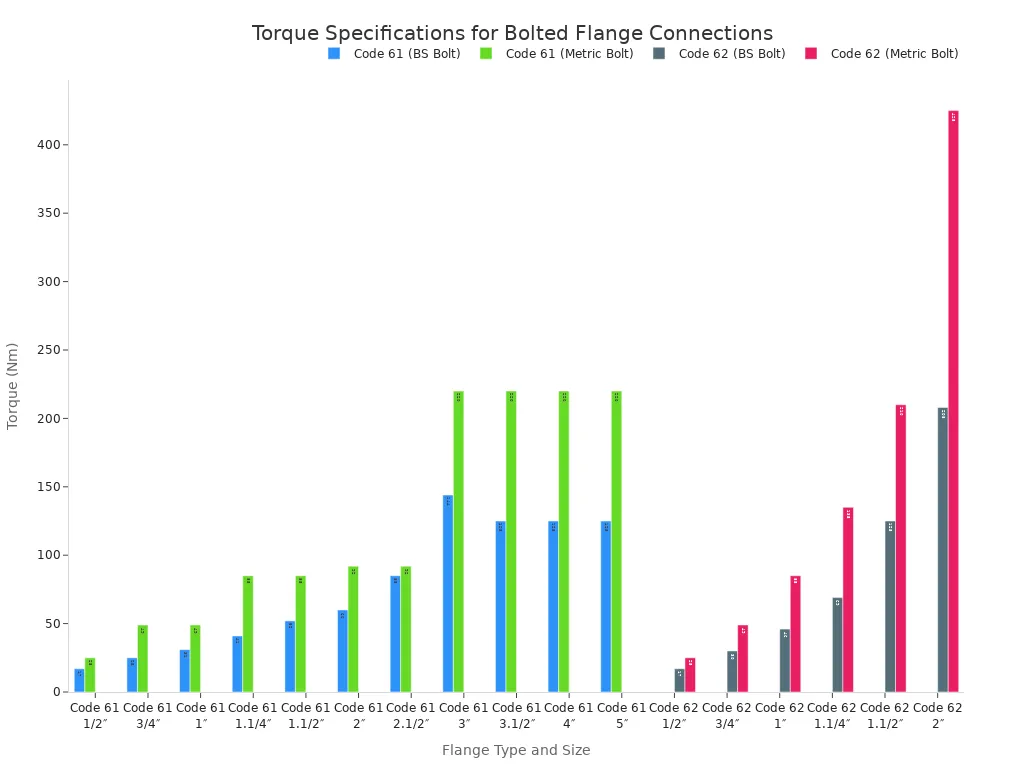

Proper Installation Techniques for High-Pressure Connections

Proper installation techniques are vital for high-pressure connections. They prevent leaks and ensure system reliability. For bolted flange connections, accurately understanding and adhering to tightening torque specifications is essential. These specifications vary by flange type, bolt size, and material. They indicate the precise rotational force needed for optimal sealing without causing damage. Following these guidelines helps avoid uneven bolt loads, flange distortion, and potential leaks or failures under pressure. Always consult manufacturer specifications or SAE J518 standards for correct torque settings.

Avoiding Common Mistakes and Ensuring Longevity of High-Pressure Fittings

Preventing common errors and maintaining high-pressure fittings extends their operational life. Proper selection, installation, and ongoing care are essential for system integrity.

Mismatched Components and Material Incompatibility

Using incompatible materials in high-pressure systems creates significant risks. For example, when carbon steel and stainless steel come into contact in an electrolyte, such as water or salt, galvanic corrosion occurs. The more reactive metal, carbon steel, corrodes. This process leads to rusting, leaks, and potential contamination of the pipe’s contents. Ultimately, this corrosion causes pipe failure. Such failures necessitate repairs and replacements, resulting in production stoppages and increased costs for companies. Engineers must ensure all components are chemically compatible with the fluid and with each other.

Importance of Regular Inspection and Maintenance Schedules

Regular inspection and maintenance schedules are crucial for the longevity of high-pressure fittings. Proactive maintenance identifies potential issues before they escalate into costly failures. Technicians should establish a routine for checking all connections, seals, and surfaces. This includes visual inspections, pressure checks, and functional tests. Adhering to manufacturer guidelines for service intervals and replacement parts ensures optimal performance. A well-maintained system operates efficiently and safely.

Recognizing Signs of Wear, Fatigue, and Potential Failure

System operators must recognize signs of wear, fatigue, and potential failure in high-pressure fittings. Early detection prevents catastrophic incidents. Key indicators include:

- Micro-cracking

- Slight deformations

- Visible cracks on the fitting body

- Surface warping or bulging

- Discoloration, which indicates material weakening

Any of these signs warrant immediate investigation and corrective action. Addressing these issues promptly helps maintain system reliability and safety.

Selecting high-pressure pipe fittings demands careful evaluation of material compatibility, pressure ratings, and fitting types. Engineers must balance safety, performance, and cost-effectiveness for optimal system design. Informed choices ensure system reliability and longevity, safeguarding operations and personnel. This proactive approach prevents costly failures and maintains operational integrity.

FAQ

What is the difference between operating pressure and design pressure?

Operating pressure refers to the normal pressure a system experiences during use. Design pressure represents the maximum pressure a system can safely endure. This includes potential surges. Engineers use design pressure for safety calculations.

Why is 316 stainless steel often preferred over 304 for high-pressure systems?

316 stainless steel includes molybdenum. This addition significantly enhances its resistance to corrosion and chlorides. It performs better in marine, chemical, and high-moisture environments. This makes it superior to 304 for demanding applications.

When should one choose welded fittings for high-pressure connections?

Welded fittings create permanent, high-integrity connections. They are ideal for critical applications requiring maximum leak prevention and structural strength. Industries like oil and gas often use them for pipelines.

What are the main advantages of using compression fittings?

Compression fittings offer quick installation without welding or threading. They provide precision, leak-tight seals. Their design also allows for easy disassembly and reassembly. This simplifies maintenance and component replacement.

What risks arise from using mismatched pipe components?

Mismatched components, especially incompatible materials, cause significant risks. They lead to galvanic corrosion, rust, and leaks. This compromises system integrity and safety. Such failures necessitate costly repairs and downtime.