Compact ball valves offer superior durability, minimal maintenance, and efficient design for residential Water Supply Systems. This ensures significant long-term savings for homeowners; average plumbing repairs cost $338. Robust PVC Ball Valves or those with HDPE Fittings and PPR Pipe Fittings provide reliable performance. Homeowners gain financial benefits and peace of mind, even with Plastic Faucets or general PPR Fittings, by choosing these valves.

Key Takeaways

- Compact ball valves save money. They last a long time and need little repair.

- These valves are easy to put in. This means less work time and lower costs.

- Compact ball valves stop leaks well. This protects homes from water damage.

Understanding the True Value: Beyond Initial Price

Homeowners often focus on the immediate price tag of plumbing components. However, a comprehensive understanding of true value extends far beyond this initial investment. It encompasses long-term savings, avoids hidden costs, and considers the critical role of material selection.

Initial Investment Versus Lifetime Savings

A compact ball valve’s initial purchase price represents only one part of its overall cost. Homeowners must consider the valve’s entire lifespan. While some traditional valve types might appear cheaper upfront, their long-term expenses often outweigh any initial savings. Compact ball valves, with their robust design and reliable operation, minimize the need for frequent repairs or replacements. This translates into significant savings over many years. They offer a superior return on investment by reducing maintenance calls and preventing costly water damage.

Hidden Costs of Traditional Valve Alternatives

Traditional valve alternatives, such as gate valves, often carry substantial hidden costs that homeowners overlook. These expenses can quickly accumulate, making the seemingly cheaper option far more expensive in the long run.

| Cost Type | Gate Valves |

|---|---|

| Initial Cost | Generally lower, making them a cost-effective choice upfront. |

| Long-term Cost | Higher maintenance needs increase overall long-term expenses. |

Replacing a shut-off valve, especially if it involves closing the municipal main line, often requires permit fees. Excavation fees become necessary for underground valves. This involves digging, breaking slabs, or trenching, costing $5 to $12 per linear foot. Utility lines, concrete, or tree roots can further increase these excavation costs. Undetected faulty valves can cause significant damage, requiring additional water line repairs. These repairs can push replacement costs beyond $1,000.

Labor costs also contribute significantly to the overall expense. Plumbers typically charge $75 to $150 per hour. A job taking 1 to 2 hours results in labor costs of $150 to $300. While the valve itself might range from $10 to $100, replacing a gate valve can cost $20 to $200. Additional fees, such as $50 to $150, apply for hard-to-reach areas or emergency services. Valves located in difficult-to-access spots—behind walls, under floors, or within cabinetry—can increase costs to $200-$750. Valves underground or beneath concrete slabs requiring excavation can escalate expenses to $1,000 or more.

The Role of Material in Cost-Effectiveness

The material composition of a compact ball valve significantly impacts its cost-effectiveness. Different materials offer varying levels of durability, performance, and price points.

| Factor | PVC Ball Valves | Brass Ball Valves |

|---|---|---|

| Initial Purchase Cost | Significantly cheaper due to lower raw material and production costs. | Higher upfront price. |

| Installation & Labor Costs | Lightweight, easier, and faster to install (lower labor fees). | Heavier, requires more careful handling, potentially increasing installation time and labor. |

| Maintenance & Replacement | More prone to cracking from temperature fluctuations or UV exposure, leading to frequent replacements. | Longer service life, corrosion-resistant, temperature tolerant, requires less frequent maintenance. |

| Application-Driven Cost Efficiency | Economical for low-pressure, non-potable systems (e.g., irrigation). | Often necessary for high-temperature, high-pressure, or potable water systems due to strength, safety, and longevity. |

| Regulatory & Compliance | May not meet certain standards for hot or drinking water. | Low-lead brass required for potable water systems, increasing price but ensuring compliance and safety. |

PVC ball valves offer a lower initial purchase cost due to cheaper raw materials and production. They are lightweight, making installation easier and faster, which reduces labor fees. However, PVC can be prone to cracking from temperature fluctuations or UV exposure, leading to more frequent replacements. They are economical for low-pressure, non-potable systems like irrigation.

Brass ball valves have a higher upfront price. They are heavier, requiring more careful handling during installation, potentially increasing time and labor. Brass offers a longer service life, corrosion resistance, and temperature tolerance, requiring less frequent maintenance. These valves are often necessary for high-temperature, high-pressure, or potable water systems due to their strength, safety, and longevity. For potable water applications, low-lead brass is required, which increases the price but ensures compliance and safety. Brass fittings are consistently more expensive than PVC, impacting profit margins or competitive pricing. Brass is about eight times denser than PVC, leading to significantly higher freight costs for shipments over time. Additionally, sourcing specific, more expensive lead-free alloys for potable water applications further increases costs.

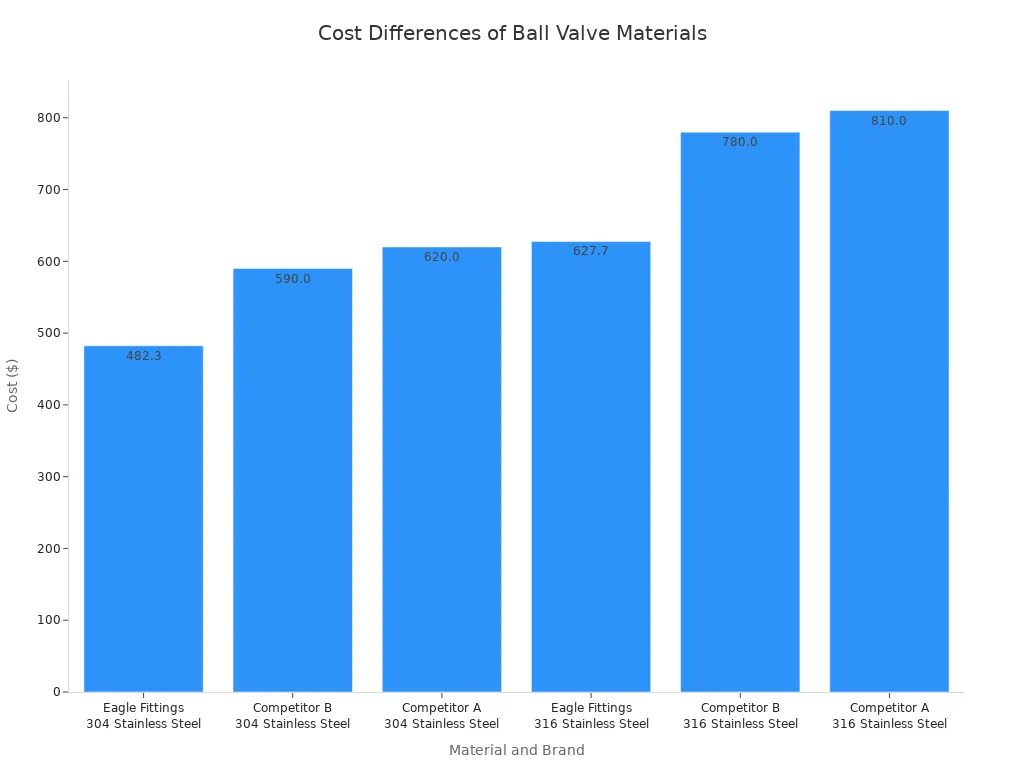

Sanitary valves made from corrosion-resistant metals like 304 or 316 stainless steel are generally more expensive than those made from cast iron or brass. The cost differences for a 2 1/2 inch ball valve illustrate this point:

| Material/Brand | Cost Range (2 1/2 Inch Ball Valve) |

|---|---|

| Standard Brass | $100–$200 |

| Sanitary Stainless Steel 3PC (Top Brands) | Exceeds $800 |

| Eagle Fittings 304 Stainless Steel | $482.30 |

| Eagle Fittings 316 Stainless Steel | $627.70 |

| Competitor A 304 Stainless Steel | $620.00 |

| Competitor A 316 Stainless Steel | $810.00 |

| Competitor B 304 Stainless Steel | $590.00 |

| Competitor B 316 Stainless Steel | $780.00 |

This comparison highlights that while initial costs vary widely by material, the most cost-effective choice depends on the specific application, required durability, and long-term performance expectations.

Durability, Ease of Installation, and Reduced Maintenance

Compact ball valves offer significant advantages in residential plumbing systems. Their design prioritizes long-term performance, straightforward installation, and minimal upkeep. These characteristics directly translate into substantial cost savings and increased reliability for homeowners.

Robust Construction for Extended Lifespan

The inherent design of compact ball valves contributes significantly to their extended operational life. Manufacturers construct these valves from high-quality materials, ensuring resilience against wear and tear. For instance, stainless steel ball valves demonstrate remarkable longevity, often exceeding 20 years in residential systems. Brass ball valves also offer impressive durability, typically lasting between 20 and 30 years. This extended lifespan means homeowners replace valves less frequently, avoiding recurring material and labor costs.

Specific design features further enhance the durability of these valves. A three-piece design, for example, allows for the replacement of seals. This capability extends the valve’s lifespan by enabling repair instead of full replacement when a seal fails. The choice of seal material also plays a crucial role. Manufacturers often use PTFE (polytetrafluoroethylene) as the standard seal material. For enhanced protection against corrosives or abrasives, they may use RPTFE (reinforced PTFE). These material choices contribute directly to the valve’s overall durability and reliable performance over many years.

Simplified Installation and Labor Cost Reduction

Compact ball valves simplify the installation process for plumbers and homeowners alike. Their straightforward design and smaller footprint make them easier to handle and position within tight spaces common in residential plumbing. This ease of installation directly reduces labor time. Plumbers can complete tasks more quickly, which translates into lower labor costs for the homeowner. The simple quarter-turn operation also means less complex piping configurations compared to some traditional valve types. This reduces the potential for installation errors and subsequent rework. Homeowners benefit from a faster, more efficient plumbing project, minimizing disruption and expense.

Minimal Maintenance Requirements for Long-Term Savings

One of the most compelling cost-effective features of compact ball valves is their minimal maintenance requirement. Unlike gate valves, which can seize up or leak due to internal corrosion and require regular exercising, ball valves maintain their integrity with little intervention. Their simple internal mechanism, consisting of a rotating ball with a bore, prevents debris accumulation and ensures a tight seal.

While compact ball valves require minimal maintenance, a structured approach ensures their optimal performance and extends their lifespan even further. Upon installation, an initial inspection identifies any damage or issues. This includes a visual check for physical damage, wear, corrosion, and tight connections. A function test also ensures smooth operation and accurate position indication. Daily checks involve a quick visual inspection for leaks, damage, abnormal operation, and position indicator accuracy. More detailed inspections, conducted weekly or monthly, include checking lubrication levels, inspecting seals and gaskets for wear, and adjusting stem packing for leaks. Quarterly or semi-annual checks involve a comprehensive inspection of internal components like the ball, seats, and stem, along with flow control adjustments if necessary. Annual maintenance typically involves a complete overhaul, including disassembly, cleaning, inspection, replacement of worn parts, reassembly, and a final function test. Regular cleaning of exterior and internal components (after disassembly) with mild detergent and lubrication of moving parts with compatible lubricants, as per manufacturer recommendations, also contribute to longevity. Furthermore, regular inspection for wear, damage, or deterioration of seals and gaskets, followed by immediate replacement with specific parts, prevents leaks and maintains efficiency. This proactive, yet infrequent, maintenance schedule ensures the valves operate reliably for decades, significantly reducing the likelihood of costly emergency repairs and contributing to substantial long-term savings for homeowners.

Performance, Versatility, and Avoiding Costly Repairs with Plastic Faucets

Compact ball valves deliver superior performance and adaptability in residential plumbing. They also help homeowners avoid expensive repairs, even with components like Plastic Faucets. Their design ensures efficient water flow and reliable shut-off.

Efficient Flow and Reliable Shut-Off Capabilities

Compact ball valves provide efficient flow and reliable shut-off. They create minimal flow resistance, resulting in a very low pressure drop. This ensures water moves freely through the system. While gate valves offer higher flow capacity when fully open, ball valves are more compact. They also offer a predictable relationship between valve position and flow rate in moderate throttling applications.

Ball valves are highly favored for their excellent shut-off capabilities. They use a spherical ball with a central bore. When perpendicular to the flow, this ball creates a reliable seal. The tight seal formed by the ball and its seat, often made of Teflon, ensures minimal water leakage when closed. This design supports full flow and offers quick shutoff. It makes them ideal for residential systems, protecting even delicate Plastic Faucets.

Versatility Across Residential Plumbing Applications

Compact ball valves demonstrate great versatility across residential plumbing applications. Homeowners use them for water main shut-offs and hot water heater connections. They also control individual water lines to appliances like dishwashers and washing machines. Furthermore, they are excellent for outdoor spigots. CPVC ball valves, a type of compact ball valve, handle both hot and cold water systems. They withstand temperatures up to 180°F, making them ideal for heating applications. Their corrosion resistance and durability ensure longevity in wet environments. This versatility makes them suitable for systems featuring various components, including Plastic Faucets.

Preventing Leaks and Water Damage

Compact ball valves excel at preventing leaks and water damage. They achieve a leak-proof seal by forcing seats, typically made of PTFE, to press tightly against the ball surface when closed. This mechanism results in low chances of leakage. High-standard ball valves can even achieve an absolute zero leak condition, known as “bubble-tight” sealing. This completely stops media flow. Gate valves, in contrast, are prone to leakage over time. This superior sealing capability protects homes from costly water damage, safeguarding entire plumbing systems, including any Plastic Faucets. Choosing these valves minimizes the risk of unexpected repairs.

Compact ball valves offer exceptional durability, minimal maintenance, and easy installation. These features make them the most cost-effective choice for residential plumbing. Their reliable performance and long lifespan provide substantial long-term savings and peace of mind for homeowners. Investing in compact ball valves ensures a more efficient, reliable, and economical plumbing system for years.

FAQ

What makes compact ball valves a cost-effective choice?

Compact ball valves offer superior durability and minimal maintenance. This reduces long-term repair and replacement costs for homeowners, providing significant savings over time.

How long can homeowners expect compact ball valves to last?

Stainless steel ball valves often last over 20 years. Brass ball valves typically perform reliably for 20 to 30 years, ensuring long-term system integrity.

Do compact ball valves require extensive maintenance?

No, they require minimal maintenance. Their simple design prevents debris accumulation and ensures a tight, reliable seal, reducing the need for frequent upkeep.