Industrial Pipe Fittings are essential components that connect pipe sections in various industrial systems. They facilitate changes in direction, size, and flow, ensuring operational integrity. Material selection is crucial for Industrial Pipe Fittings because it directly impacts system performance, safety, and longevity. For instance, choosing corrosion-resistant thermoplastic fittings, such as Plastic Pipe Fittings like PVC Ball Valves or HDPE Pipe Fittings, is vital for specific chemical processes. The global pipe fittings market, valued at USD 70 billion in 2024, highlights their significance. Even a simple 90° Elbow requires careful material consideration for optimal function.

Key Takeaways

- Choosing the right material for industrial pipe fittings is very important. It affects how well the system works, its safety, and how long it lasts.

- Engineers must think about pressure, temperature, and what liquid the pipes will carry. Different materials work best for different conditions.

- Materials like stainless steel fight rust well. Plastics like PVC and HDPE are good for chemicals and are lighter. Each material has its own strengths.

- Always follow industry rules and standards when picking pipe fittings. This makes sure everything is safe and works correctly.

- Good choices in pipe fitting materials help prevent problems. They also make systems last longer and cost less to maintain over time.

Metallic Industrial Pipe Fittings: Properties and Applications

Metallic industrial pipe fittings form the backbone of many critical systems, offering strength, durability, and resistance to various operational stresses. Their material properties dictate their suitability for specific environments.

Stainless Steel Industrial Pipe Fittings

Stainless steel industrial pipe fittings are highly valued for their excellent corrosion resistance and strength. They find widespread use in environments requiring hygiene, such as food processing, or resistance to corrosive media. Two common grades, 304 and 316, offer distinct advantages.

| Mechanical properties | 304 stainless steel | 316 stainless steel |

|---|---|---|

| Ultimate Tensile Strength | 73200 psi | 79800 psi |

| Tensile Yield Strength | 31200 psi | 34800 psi |

| Corrosion resistance | Excellent | Even better |

While both grades exhibit similar tensile strengths, 316 stainless steel provides superior corrosion resistance, particularly in chemical and marine environments. This enhanced resistance to pitting and crevice corrosion comes from its 2-3% molybdenum content. This makes 316 ideal for applications involving chlorides, acids, and alkalis.

Carbon Steel Industrial Pipe Fittings

Carbon steel industrial pipe fittings are a workhorse in heavy industries due to their robustness and cost-effectiveness. They offer high strength, durability, and resistance to significant pressures and temperatures. Industries like oil and gas, power generation, and chemical processing frequently utilize carbon steel. These fittings, with carbon content ranging from 0.06% to 1.5%, withstand extreme pressure without failure.

| Fitting Type | Operating Pressure (Max) | Temperature Range |

|---|---|---|

| Streamline® STL-G (Gas & Fuel/Oil) | 125 PSI (fuel gas), 200 PSI (other approved) | -40°F to 180°F |

| Streamline® STL (Mechanical & Fire Sprinkler) | 200 PSI CWP | -40°F to 250°F |

Their toughness and corrosion resistance also make them viable for harsh conditions, ensuring reliability in demanding high-pressure and high-temperature applications.

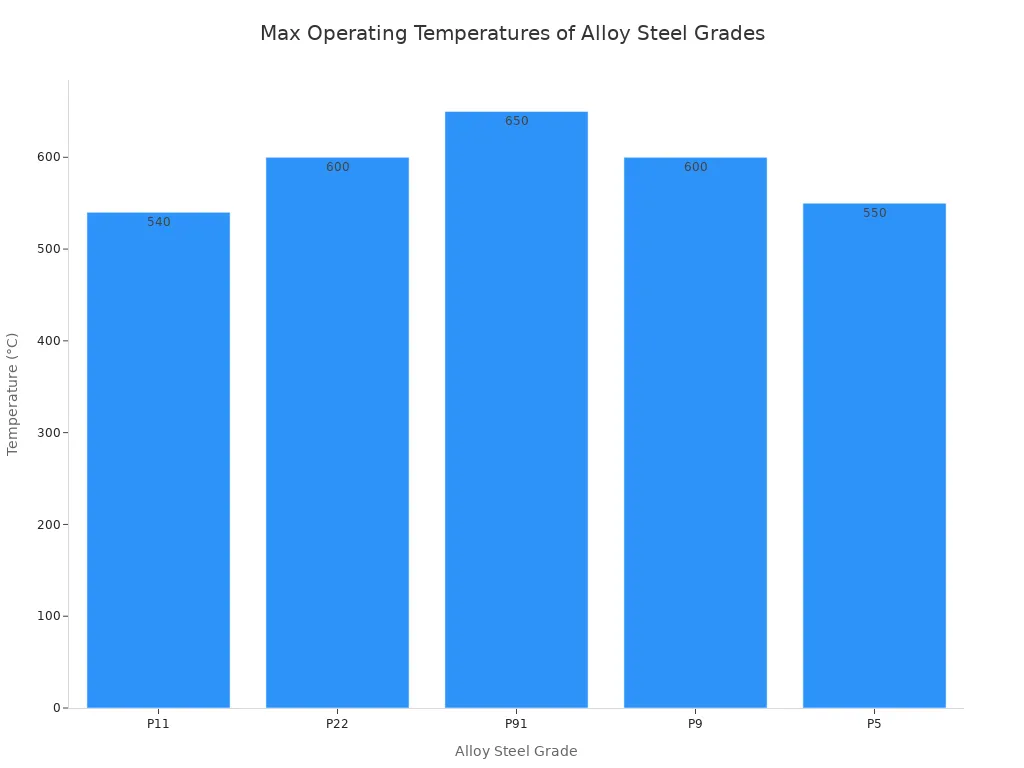

Alloy Steel Industrial Pipe Fittings

Alloy steel industrial pipe fittings are engineered for extreme conditions, offering enhanced performance where standard carbon or stainless steels fall short. These fittings contain specific alloying elements like chromium and molybdenum, which improve their strength, creep resistance, and oxidation resistance at elevated temperatures and pressures. Grades under ASTM A335 (ASME SA335), such as P5, P9, P11, P22, and P91, are commonly used.

| Specification | Details |

|---|---|

| Grades Available | F1, F5, F9, F11, F22, F91 |

| Pressure Rating | Up to 9000 PSI |

| Temperature Range | -46°C to 675°C |

Each grade offers a unique balance of properties. For example, F91 provides exceptional creep strength and high-temperature endurance, making it suitable for ultra-high-pressure environments.

These specialized alloys ensure system integrity in the most challenging industrial settings.

Copper and Brass Industrial Pipe Fittings

Copper and brass industrial pipe fittings offer distinct advantages for specific applications, primarily due to their excellent corrosion resistance and thermal properties. Industries often choose these materials for their reliability in certain fluid transfer systems.

Copper industrial pipe fittings are highly valued for their exceptional thermal conductivity and resistance to corrosion from water. Manufacturers commonly use copper in plumbing, heating, ventilation, and air conditioning (HVAC) systems. Its ductility allows for easy shaping and installation, making it a versatile choice for various configurations. Copper also resists bacterial growth, which makes it suitable for potable water systems. However, copper fittings generally have lower strength compared to steel and are not ideal for very high-pressure or high-temperature environments.

Brass, an alloy of copper and zinc, provides enhanced strength and machinability over pure copper. These industrial pipe fittings are durable and resist corrosion well, particularly in water and gas applications. Brass fittings are common in gas lines, low-pressure fluid transfer systems, and decorative plumbing fixtures. Their good machinability allows for precise manufacturing of complex shapes. While brass offers better strength than copper, it still does not match the pressure and temperature capabilities of steel alloys. Some brass alloys can also be susceptible to dezincification in certain aggressive water conditions, which can compromise their integrity over time. Both copper and brass fittings are crucial components in systems where their specific material properties align with operational demands.

Non-Metallic Industrial Pipe Fittings: Characteristics and Uses

Non-metallic industrial pipe fittings offer distinct advantages in applications where corrosion resistance, flexibility, and lighter weight are paramount. These materials provide effective solutions for various fluid transfer needs, often at lower costs than their metallic counterparts.

PVC and CPVC Industrial Pipe Fittings

Polyvinyl Chloride (PVC) and Chlorinated Polyvinyl Chloride (CPVC) industrial pipe fittings are widely used for their excellent chemical resistance and cost-effectiveness. Manufacturers often choose them for water treatment, chemical processing, and waste management systems. CPVC, in particular, offers superior temperature and pressure capabilities compared to standard PVC. For instance, Corzan CPVC can handle pressurized service up to 200°F. This material also provides a higher pressure rating across most of its useful temperature range compared to other thermoplastic materials. Other thermoplastics like PVC, polypropylene, or HDPE typically have maximum pressurized service temperatures as low as 140°F or 160°F. Some HDPE grades might be pressure-rated up to 180°F, but their maximum pressure at elevated temperatures remains lower than Corzan CPVC.

PEX Industrial Pipe Fittings

Cross-linked polyethylene (PEX) industrial pipe fittings have gained popularity for their flexibility, durability, and ease of installation. PEX pipes are more cost-effective than copper or steel pipes due to lower material costs. Their flexibility allows them to bend around corners and obstacles, reducing the need for multiple fittings and connections. This simplifies installation and minimizes potential leak points. This adaptability leads to faster installation times and lower labor costs. PEX pipes are also lightweight and easier to handle, contributing to overall installation efficiency and cost savings.

HDPE Industrial Pipe Fittings

High-density polyethylene (HDPE) industrial pipe fittings are known for their robustness, flexibility, and exceptional chemical resistance. They are a preferred choice for municipal water systems, gas distribution, and industrial fluid transfer. HDPE is highly resistant to acids, alkalis (bases), and salts. This resistance prevents material breakdown or reaction with transported fluids. HDPE maintains its mechanical strength even after prolonged chemical exposure. It is inert and does not leach harmful substances, making it suitable for potable water applications. HDPE also resists common chemicals, acids, and solvents, making it a suitable option for underground piping due to its resistance to strong acids and bases naturally occurring in soil.

Fiberglass Reinforced Plastic (FRP) Industrial Pipe Fittings

Fiberglass Reinforced Plastic (FRP) industrial pipe fittings offer a compelling solution for demanding environments where traditional metallic options fall short. These fittings excel due to their exceptional corrosion resistance and impressive strength-to-weight characteristics. FRP can be specifically formulated to achieve extreme corrosion resistance, making it an ideal material for highly aggressive applications. This material exhibits excellent resistance across a wide range of chemical applications, including organic and inorganic compounds, as well as alkaline and acidic environments. Manufacturers can further enhance this superior corrosion resistance through modifications to the corrosion barrier based on specific design specifications.

FRP also provides a significantly higher strength-to-weight ratio compared to steel. For equivalent thicknesses and sizes, fiberglass weighs only one-seventh as much as steel. This makes FRP notably lightweight, weighing less than 20% of steel, while still offering excellent strength. In fact, FRP is stronger than steel on an equal weight basis. This lighter weight translates to easier handling and reduced loads on support structures. Fiberglass pipe is inherently corrosion resistant and offers a long service life, often exceeding 30 years. This makes it a desirable alternative to steel and other metal alloys in corrosive settings. While steel generally possesses higher mechanical and tensile strength (456 MPa for steel versus 80-135 MPa for FRP), FRP’s superior corrosion resistance and lighter density (1850 kg/cu.m compared to steel’s 7800 kg/cu.m) make it a more economical long-term solution for many industrial pipe fittings applications.

Specialized Industrial Pipe Fittings for Demanding Environments

Certain industrial applications present extreme conditions that require materials beyond standard metallic or non-metallic options. Specialized industrial pipe fittings address these challenges, offering enhanced durability, corrosion resistance, and performance in the harshest environments.

Ductile Iron Industrial Pipe Fittings

Ductile iron industrial pipe fittings are crucial for demanding infrastructure projects. They offer exceptional impact resistance and cost-effectiveness. These fittings can withstand significant impacts and vibrations, making them suitable for urban environments with ground movement. Their robust nature allows them to handle high-pressure applications, heavy earth and traffic loads, and unstable soil conditions. Industries widely use ductile iron in water distribution, sewage and wastewater systems, and fire protection systems. Modern ductile iron pipes and fittings are designed for longevity, with a projected service life exceeding 100 years. This long lifespan contributes significantly to cost savings over time.

Nickel Alloy Industrial Pipe Fittings

Nickel alloy industrial pipe fittings provide superior performance in highly corrosive environments. Monel Alloy 400, for example, resists chloride ion stress corrosion cracking. It performs well in reducing environments and withstands most alkalis, salts, and organic substances. Monel is ideal for marine applications and acidic conditions. Inconel alloys, such as 625 and 718, offer excellent corrosion resistance in high-temperature and harsh settings. They resist oxidation, acids, alkalis, and chlorides. Manufacturers use Inconel in chemical processing, high-temperature gas applications, and high-pressure steam systems. These alloys ensure system integrity where other materials would fail.

Titanium Industrial Pipe Fittings

Titanium industrial pipe fittings are essential for aerospace and marine applications due to their unique properties. Titanium possesses a high strength-to-weight ratio. It is as strong as steel but approximately 45% lighter. This characteristic significantly reduces aircraft weight, improving fuel efficiency. In aerospace, titanium’s resistance to corrosive jet fuel and hydraulic oils ensures reliability. For marine environments, titanium exhibits immunity to seawater corrosion and biofouling. This makes it ideal for desalination plant piping and submarine fittings. Its lightweight nature also enhances performance in marine systems.

Selecting the Right Industrial Pipe Fittings Material

Choosing the correct material for industrial pipe fittings is a critical decision. This choice directly impacts system safety, efficiency, and long-term operational costs. Engineers consider several key factors during the selection process.

Pressure and Temperature Considerations

System pressure and temperature are primary determinants for material selection. Each material has specific limits it can safely withstand. Elevated temperatures significantly reduce the maximum working pressure capability of tubing systems. To determine the maximum allowable working pressure at higher temperatures, engineers multiply the tube’s maximum allowable working pressure by a corresponding temperature stress factor. Specific derating factors for materials like 304SS, 316SS, and Carbon Steel are available in relevant tables. Stainless steel demonstrates better strength retention at elevated temperatures compared to carbon steel. This makes stainless steel a more suitable choice for high-temperature applications where pressure integrity is paramount.

Fluid Compatibility and Corrosion Resistance

The type of fluid transported through the piping system dictates the required corrosion resistance of the fittings. Different chemicals react differently with various materials. Galvanic corrosion poses a significant risk when dissimilar metals come into contact with an electrolyte. For galvanic corrosion to occur, three factors must be present: metals with different electrical potential, an electron path connecting the two metals, and a conductive electrolyte solution. In crude oil or gas services, if a conductive electrolyte like salty brine water is present, galvanic corrosion becomes a possibility.

Galvanic corrosion happens when two different metals touch an electrolyte, such as water or salt. This causes the more basic metal to corrode. Real-world examples include copper pipe connected to galvanized steel, where the zinc coating on the galvanized steel corrodes near the connection point. Another example is stainless steel fasteners on carbon steel supports, where the carbon steel corrodes around the joint. Marine environments also show rapid degradation of aluminum hulls in contact with steel supports or copper skin due to saltwater’s high conductivity. Closed-loop systems are vulnerable if initial fill water has high conductivity. These systems commonly use dissimilar materials like copper, stainless steel, and carbon steel. Improper or degraded corrosion inhibitors fail to protect vulnerable metals. Micro-leaks introduce oxygen, increasing conductivity and corrosion potential. Conditions accelerating galvanic corrosion include high conductivity from dissolved solids like chlorides and sulfates, low or unstable pH, biological activity releasing organic acids and gases, and temperature and pressure extremes, which increase reaction rates and ion mobility.

Cost-Effectiveness and Longevity

The initial cost of industrial pipe fittings is only one part of the equation. Engineers must also consider the material’s expected lifespan and maintenance requirements. Carbon steel pipe fittings generally last between 15 and 30 years. Environmental conditions, installation quality, and maintenance practices influence this lifespan. Proper protection and installation in moderate environments can lead to longer operational life. Harsh conditions may necessitate more frequent replacements. Regular inspection and maintenance are crucial for extending their service life.

Here is a comparison of typical lifespans for various pipe materials:

| Pipe Material | Typical Lifespan |

|---|---|

| HDPE | 50-100 years |

| Ductile Iron | 30-50 years |

| Steel | 20-40 years |

| Copper | 40-70 years |

HDPE typically offers a 25-100% longer service life compared to metallic alternatives in corrosive environments. It also has a comparable lifespan to other plastics in benign conditions. Its combination of corrosion resistance, flexibility, and joint integrity provides a significant lifespan advantage, especially in aggressive soil and water conditions.

Other materials also have varying lifespans:

- Carbon Steel: 20–50 years (shorter with corrosive contents or poor coating)

- Stainless Steel: 50+ years (excellent for chemical resistance, but can suffer from stress corrosion)

- PVC/HDPE: 25–50 years (performance depends on temperature, pressure, and chemical exposure)

Adherence to Industry Standards and Regulations

Adhering to industry standards and regulations is paramount when selecting industrial pipe fittings. These guidelines ensure safety, reliability, and compatibility across various systems and components. Numerous organizations develop and enforce these standards, providing a framework for manufacturing, testing, and application.

ASTM International, for instance, provides over 12,000 global industrial material and service standards. More than 100 of these standards specifically cover steel pipe, tubing, fittings, and flanges. The American Society of Mechanical Engineers (ASME) has published standards since 1880, focusing on industrial tools, machine parts, and safety improvements for boilers and pressure vessels. ASME standards for pipe applications are extensive and often identical to ASTM standards, indicated by the ‘A/SA’ designation, such as A/SA 333. The American Petroleum Institute (API) is an industry-specific organization. It develops standards for materials used in the oil and gas industry. API standards are generally stricter and include additional testing requirements compared to other standards, though some overlap exists. For example, API 5L pipe is commonly used in oil and gas. It shares similarities with A/SA 106 and A/SA 53, but the latter do not meet all API 5L criteria. The American National Standards Institute (ANSI) was founded in 1916 to develop voluntary consensus standards in the U.S. ANSI collaborated with international organizations to form the International Organization for Standardization (ISO). ANSI also acts as an accrediting body, endorsing standards from individual organizations for global adoption. Many ASTM, ASME, and other standards, such as the ASME B16 standard for flanges, valves, fittings, and gaskets, have been endorsed by ANSI for worldwide use.

Several key industry standards govern the manufacturing and testing of industrial pipe fittings:

- ASTM Standards: The American Society for Testing and Materials develops these standards. They cover materials, dimensions, testing procedures, and performance requirements for pipe fittings, ensuring consistency and quality. Examples include ASTM A105, ASTM A234, ASTM F442, and ASTM A403.

- ANSI/ASME B16 Standards: The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) established the B16 series. It addresses dimensions, materials, pressure ratings, and design for various pipe fittings like flanges, valves, elbows, tees, and reducers. ANSI B16 standards are widely adopted for compatibility, interchangeability, and safety. Specific examples include:

- B16.47: Large diameter Steel Flanges: NPS 26 through NPS 60 metric/inch standard. This covers pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing for pipe flanges in sizes NPS 26 through NPS 60, across various rating classes.

- B16.48: Line Blanks. This specifies pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing for operating line blanks in sizes NPS 1/2 through NPS 24. They are designed for installation between ASME B16.5 flanges in various Pressure Classes.

- B16.49: Factory-made, Wrought Steel, Buttwelding Induction Bends for Transportation and Distribution systems. This addresses design, material, manufacturing, testing, marking, and inspection requirements for factory-made pipeline bends of carbon steel materials produced by the induction bending process.

- B16.5: Pipe Flanges and flanged fittings: NPS 1/2 through 24. This covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods for designating openings for pipe flanges and flanged fittings.

- B16.9: Factory-made Wrought Buttwelding fittings. This details overall dimensions, tolerances, ratings, testing, and markings for wrought carbon and alloy steel factory-made buttwelding fittings of NPS 1/2 through 48, covering any producible wall thickness.

- B1.20.1: Pipe threads, general purpose, inch. This covers dimensions and gaging of pipe threads for general purpose applications.

- ISO Standards: The International Organization for Standardization develops globally recognized standards for pipe fittings. They cover dimensions, materials, testing, and quality management. Examples include ISO 4144 and ISO 49 for threaded fittings, and ISO 5251 and ISO 3419 for butt-welded fittings.

- DIN Standards: The Deutsches Institut für Normung develops these German standards. They specify requirements for pipe fittings. Examples include DIN 2576 for plate flanges and DIN 2605 for steel butt-welding pipe fittings.

- EN Standards: The European Committee for Standardization (CEN) develops these standards. They define requirements for pipe fittings in Europe. Examples include EN 10242 for malleable cast iron threaded fittings and EN 1092 for flanges and their joints.

- MSS Standards: The Manufacturers Standardization Society of the Valve and Fittings Industry provides standards such as MSS SP-44 for steel pipeline flanges and MSS SP-75 for high-strength, low-alloy steel fittings.

- API Certifications: The American Petroleum Institute offers certifications for pipe fittings in the oil and gas industry. They cover design, materials, manufacturing, and testing to ensure reliability and safety. Examples include API 6A for wellhead equipment.

- NSF Certifications: NSF International certifies pipe fittings for potable water systems. NSF/ANSI 61 evaluates materials in contact with drinking water.

- DVGW Certifications: In Germany, the German Technical and Scientific Association for Gas and Water certifies pipe fittings for gas and water supply systems. This ensures compliance with safety and quality.

- WRAS Approvals: In the UK, the Water Regulations Advisory Scheme approves pipe fittings for public water supply systems. It verifies compliance with regulations and prevents water contamination.

- CE Marking: This is a mandatory conformity mark for products in the European Economic Area. It indicates compliance with EU directives for pressure equipment and construction products.

- UPC (Uniform Plumbing Code): IAPMO publishes this code. It sets standards for material, dimensions, construction, and performance of pipe fittings within plumbing systems in the United States.

- ABS (American Bureau of Shipping) Certification: This provides certification for pipe fittings in marine and offshore industries. It ensures compliance with ABS rules.

- DNV (Det Norske Veritas) Certification: This is relevant for pipe fittings in maritime, offshore, and oil and gas sectors. It indicates compliance with DNV rules for quality, safety, and environmental considerations.

- JIS Standards: Japanese Industrial Standards define requirements for pipe fittings in Japan. These include JIS B2311 for butt-welding fittings and JIS B2220 for steel pipe flanges.

Specific industries also have unique regulatory requirements. In the oil and gas industry, API standards, such as API 6A for wellhead and Christmas tree equipment, are critical. API certification ensures pipe fittings meet stringent safety and performance requirements. For the chemical processing industry, materials like stainless steel are vital. They withstand tough chemicals without corroding, especially for components like check valves in chemical plants. The food and beverage industry prioritizes hygiene. Materials like stainless steel are used because they are easy to clean and resist rust. Polished finishes are often required to prevent bacterial growth and maintain product purity. FDA standards also necessitate smooth, non-reactive materials. These materials tolerate a wide range of temperatures and are easy to maintain and clean.

Key Takeaways for Industrial Pipe Fittings Material Selection

Selecting the right material for Industrial Pipe Fittings requires careful consideration of operating conditions. Engineers must evaluate pressure, temperature, and fluid compatibility. Corrosion resistance, cost-effectiveness, and longevity are also crucial factors. Adherence to industry standards ensures safety and reliability.

The Impact of Informed Choices on System Performance

Informed material choices directly impact system performance and operational efficiency. Proper selection prevents failures, reduces maintenance, and extends system lifespan. This strategic approach ultimately leads to safer, more reliable, and more cost-effective industrial operations.

FAQ

What are the primary categories of Industrial Pipe Fittings?

They generally fall into metallic and non-metallic categories. Metallic options include stainless steel, carbon steel, and alloy steel. Non-metallic types feature PVC, CPVC, PEX, and HDPE. Each category serves different operational needs and environmental conditions.

Why does material choice matter for Industrial Pipe Fittings?

Material selection directly impacts system performance, safety, and longevity. The right material ensures compatibility with fluids, withstands pressure and temperature, and resists corrosion. This prevents failures and reduces maintenance costs.

What are common uses for stainless steel fittings?

Industries use stainless steel fittings in environments requiring high hygiene or corrosion resistance. These include food processing, chemical plants, and marine applications. Grades like 304 and 316 offer specific advantages for different corrosive media.

When are non-metallic fittings like PVC or HDPE preferred?

Non-metallic fittings are ideal when corrosion resistance, flexibility, and lighter weight are crucial. They suit water treatment, chemical processing, and gas distribution systems. These materials often provide cost-effective solutions for various fluid transfer needs.